Petroleum Coke

Petroleum Coke Crushing and Screening Solutions

Petroleum coke is a byproduct derived from the distillation of crude oil, which separates light and heavy oils, followed by thermal cracking of the heavy oil. It appears as irregularly shaped black blocks or particles with a metallic sheen. The primary component of petroleum coke is carbon, making up over 80% of its composition, with the remainder consisting of hydrogen, oxygen, nitrogen, sulfur, and trace metals. Due to its high carbon content and unique microcrystalline structure, petroleum coke is easily graphitized, making it an ideal raw material for producing graphite electrodes with low resistivity. Petroleum coke is extensively used in various industries, including metal smelting, chemicals, and aluminum production, as well as in the manufacture of calcium carbide, silicon carbide, and other products. It also serves as a fuel in metal casting processes.

Petroleum coke crushing and screening process

The following is the process of crushing and screening of petroleum coke, as well as the system equipment:

- Crusher: Crushes large petroleum coke pieces into smaller particles for subsequent screening.

- Bucket elevator: Lifts the crushed petroleum coke to the screening equipment.

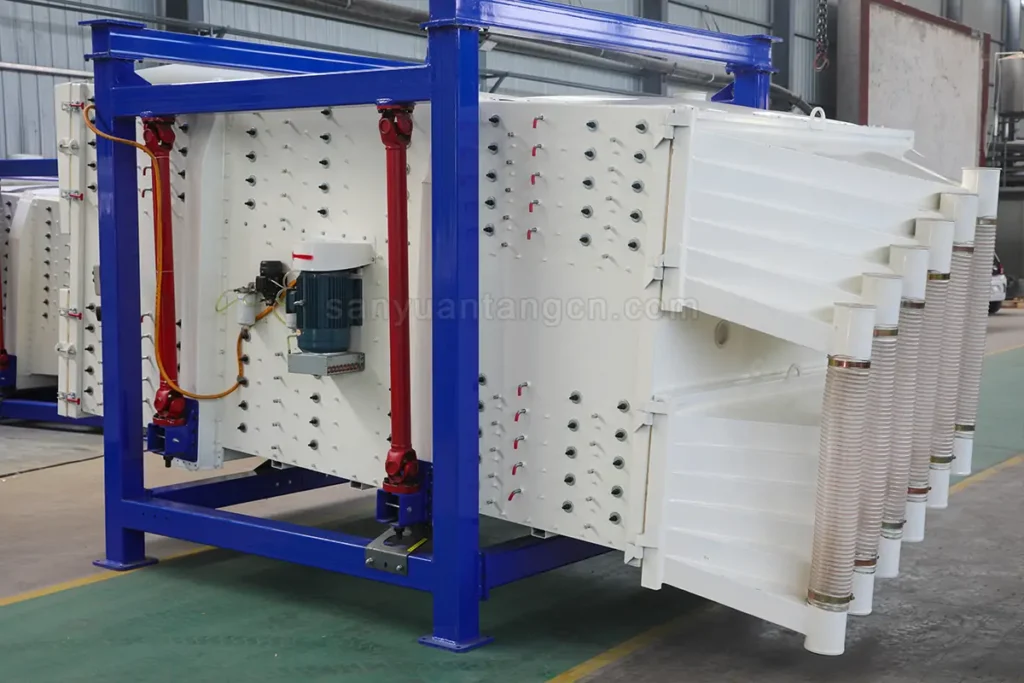

- Rectangular gyratory sifter: Multi-level fine screening to meet the screening needs of petroleum coke of different particle sizes. It has the characteristics of large output, high precision, energy saving, wear resistance, and easy maintenance.

- Vibrating feeder: feeds petroleum coke evenly into the screening equipment.

- Ton bags: used to store and transport screened petroleum coke.

Purpose of petroleum coke screening

- Remove impurities: remove impurities in petroleum coke, such as ash, sulfur and other harmful elements.

- Particle size classification: The particle size of petroleum coke affects its ignition point and combustion efficiency. Particle size classification of petroleum coke facilitates subsequent processing and utilization, and improves resource utilization.

Analysis of petroleum coke characteristics

- Easy to block mesh: The shape of petroleum coke blocks after crushing is irregular, which can easily embed into the mesh and cause mesh blockage. The equipped bouncing ball net cleaning device can effectively improve the net passing efficiency and accelerate the passage of materials.

- The discharge port is easy to wear: Due to the high hardness of petroleum coke, the discharge port of the machine is easy to wear. Sanyuantang recommends replacing the discharge port material with wear-resistant manganese steel.

Recommended solution

According to the material characteristics and screening requirements of petroleum coke, the following screening solutions are recommended:

Duplex Sand Vibrating Screen

- Material: petroleum coke

- Equipment: double vibration source gyratory sifter

- Output: 10-25 ton/h

- Screening particle size: 0-1mm, 0-2mm, 1-3mm, 1-5mm, 1-8mm, 2-8mm, 8-25mm, the screen can be customized according to the needs.

Videos

Please view our customer site video at petroleum coke screening: