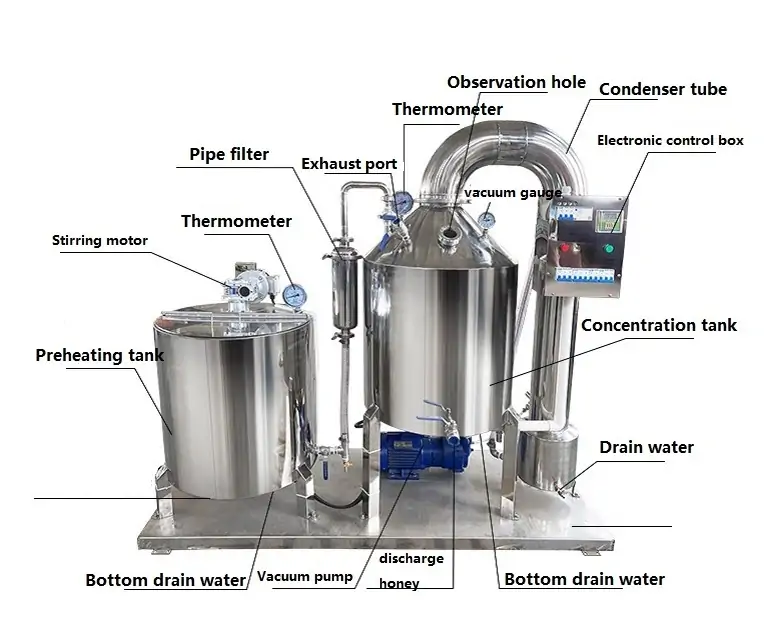

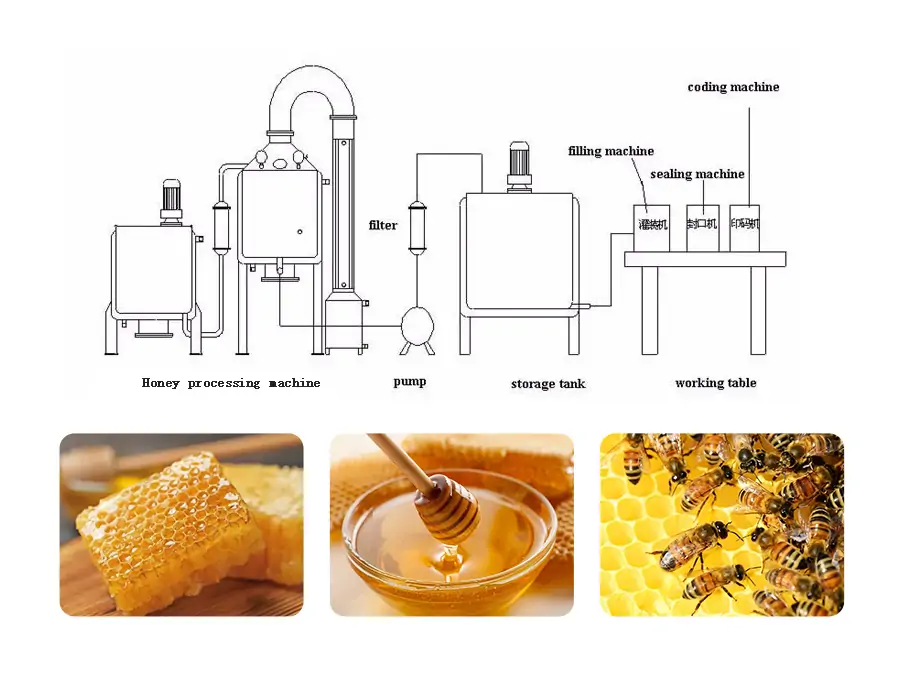

The honey processing machine also called honey concentrator, adopts an electric heating or steam heating structure, automatic temperature control, and vacuum feed, the device not only can concentrate but can sterilization, this equipment adopts 304 stainless steel, easy to operate, reliable operation, highly efficient, vacuum suction honey, can achieve higher vacuum degree and low concentrated temperature, is the ideal of honey processing equipment. Equipment includes a preheating tank, filters, concentrator, condenser, and vacuum pump.

- Function: Removing honey moisture and filtering

- Model: FM-600 FM-400

- Material: All stainless steel 304

- Vacuum degree: -0.092 Mpa

- Power: 16kw

- Concentration temperature ≤45℃

- Capacity: 0.5-1.5t per 8h

Price: $2900-3290 /Set

Working Principle

The honey processing machine adopts high-efficiency heat conduction and centrifugal separation technology. By accurately controlling the liquid level of the honey liquid in the heating tube, the honey is quickly vaporized and formed into a film by using external steam for uniform heating. At the same time, the accumulation of secondary steam enhances the film effect and promotes water evaporation. Subsequently, the steam mixture is subjected to high vacuum suction and centrifugal force in the separator, and is separated by high-speed rotation, which increases the surface area of the material and accelerates the further vaporization of water, ultimately achieving efficient concentration of honey while maintaining its flavor and nutritional value.

Structures

The equipment consists of a preheating tank, a filter, a concentration tank, a condenser, a vacuum pump, etc., and uses automatic control electric heating for heating, which is hygienic and convenient.

- Heating system: The heating system usually consists of a heater or a steam heater, which is used to provide a heat source to heat the honey, evaporate it and concentrate it.

- Evaporator: The evaporator is the core component of the honey concentrator. It usually uses a tubular evaporator or a plate evaporator to heat and evaporate the honey to achieve the effect of concentration.

- Cooling system: The cooling system usually includes a cooler or a cooling water system to cool the concentrated honey for storage and packaging.

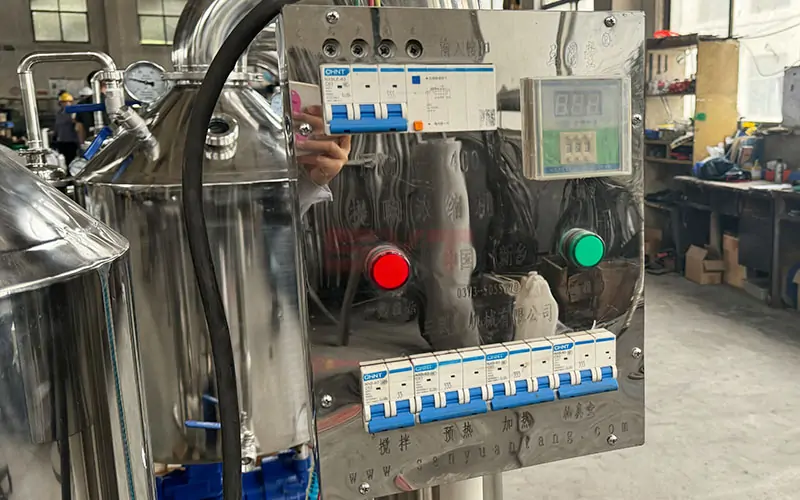

- Control system: The control system usually consists of a PLC controller or other types of controllers to monitor and adjust process parameters such as heating, evaporation and cooling to achieve automatic control.

- Feeding system: The feeding system usually includes a feeding pump and a feeding pipeline to feed the raw honey into the honey concentrator for processing.

- Discharging system: The discharging system usually includes a discharging pump and a discharging pipeline to deliver the concentrated honey from the concentrator for packaging or further processing.

- Protection system: To ensure the safety of equipment and operators, honey concentrators usually also include some protection systems, such as over-temperature protection, pressure protection, etc.

Details Show

Observation Hole

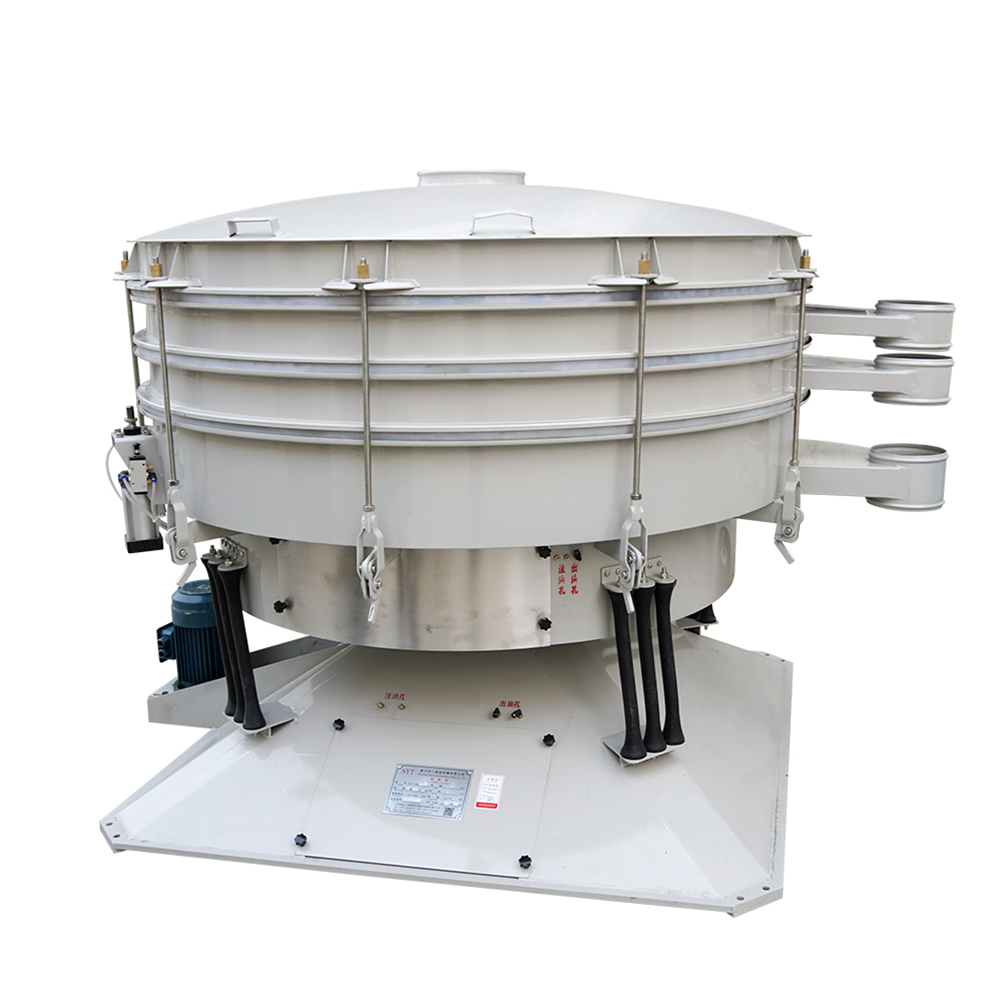

filter Screen

Vacuum Gauge

Stirring Motor

Vibration Motor

Thermometer

Electronic Control Box

Observation Hole

Technical parameters

| Model | FM600 | FM400 |

|---|---|---|

| Production capacity | 1.2-1.5 t/8h | 0.5 t/8h |

| Machine diameter | 1750*600*1660 mm | 1600*500*1555 mm |

| Tank diameter | 600 mm | 400 mm |

| Thank height | 600 mm | 600 mm |

| The overall volume | 140 L | 70 L |

| Effective volume | 120 L | 60 L |

| Preheat tank power | 6 KW | 6 KW |

| Volume concentration tank power | 9 KW | 6 KW |

| Vacuum pump power | 1.5 KW | 1.5 KW |

Features

- Integrated and efficient processing: It integrates vacuum suction, crystal dissolution, instant sterilization, rapid cooling, low-temperature concentration and continuous feeding and discharging functions to achieve comprehensive optimization of honey processing.

- Purity and quality are improved: deep sterilization, impurity removal and crystal nucleus dissolution improve the purity and quality standards of honey.

- High-efficiency and energy-saving design: wide adaptability, efficient operation and reduced energy consumption, helping to improve production efficiency and quality.

- Convenient operation and real-time monitoring: easy to operate, equipped with automatic temperature control, flow monitoring, sampling and concentration adjustment functions, to master the honey processing status throughout the process.

- Fresh-keeping and anti-deterioration technology: effectively prevent honey from browning, fermentation and crystallization, extend shelf life, and maintain natural flavor and nutrition.