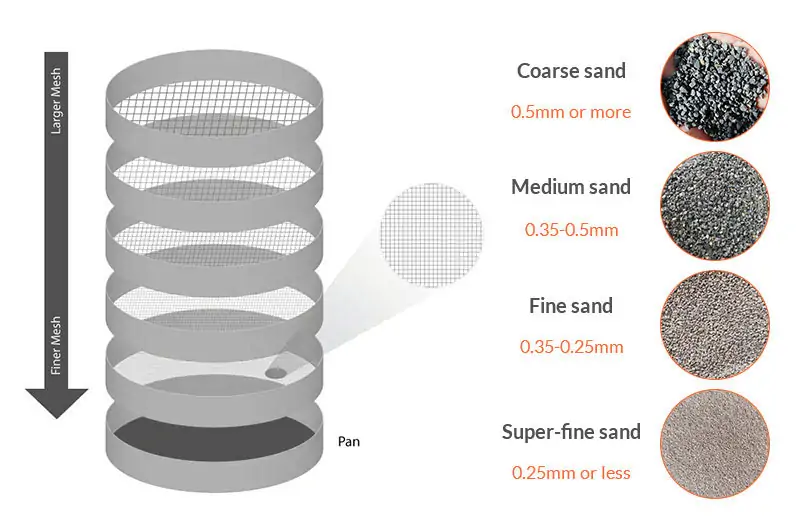

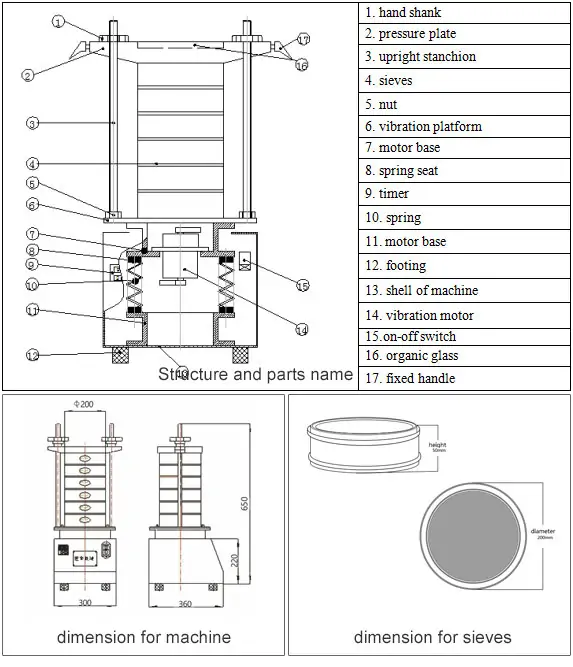

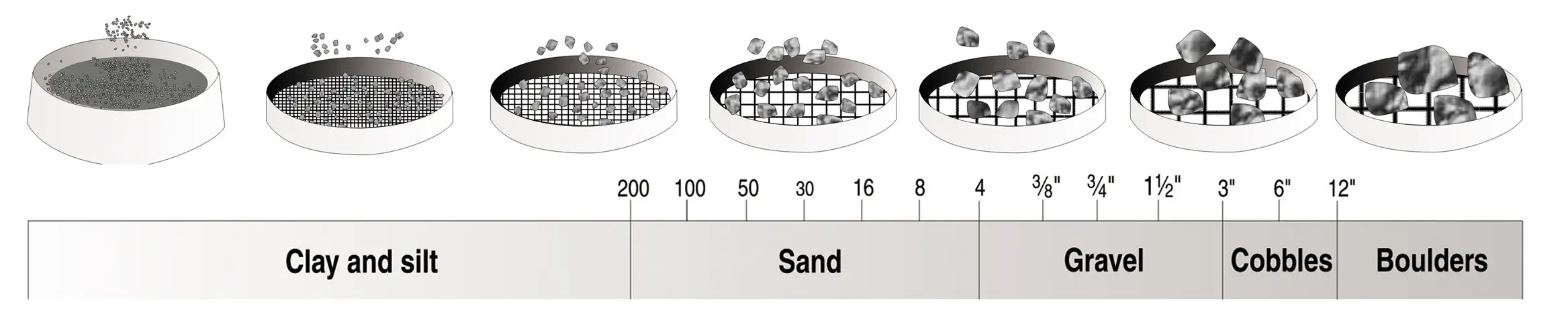

The sand test sieve set is a national standard test sieve for testing the particle size of sand and gravel in the laboratory. The equipment is mainly composed of square hole metal screens. The diameter of the screen frame is commonly 200mm and 300mm. Up to 8 layers of screens can be stacked for classification and screening at the same time. The screen aperture size is 9.5mm to 0.15mm, which can be used to test aggregates of different particle sizes such as gravel, coarse sand, and medium sand. The stone classification standards are: 9.50mm (gravel), 4.75mm (very coarse sand), 2.36mm (coarse sand), 1.18mm (medium sand), 0.6mm (fine sand), 0.3mm (very fine sand) and 0.15mm (micro-fine sand) and other particle size grades.

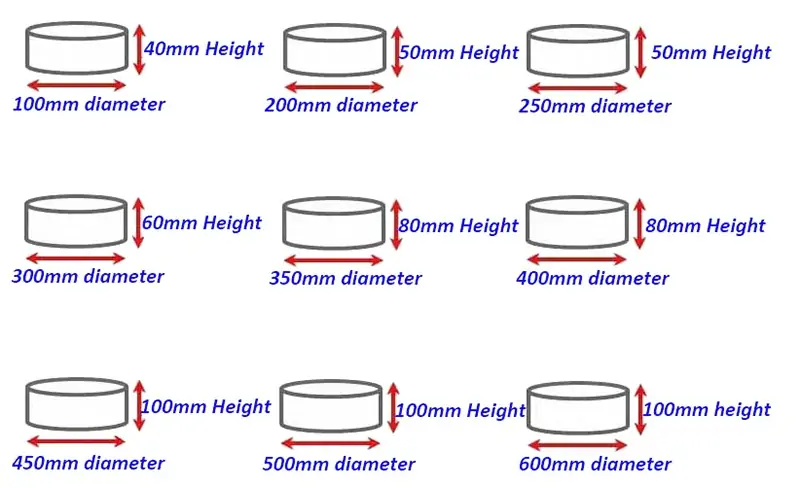

- Sieve Size: 200mm, 300mm.

- Height: 3.5cm, 5cm, 6cm, 7.5cm, 8cm, 10cm, etc.

- Specification: 0.075mm, 0.15mm, 0.6mm, 1.18mm, 2.6mm, 4.75mm, 9.5mm.

- Sieve Material: Brass, stainless steel, aluminum, PVC coated, etc.

- Aperture size: perforated plate for aperture size bigger than 1.18mm, woven mesh for aperture size smaller than 1.18mm.

working Principle

Sand and gravel test sieve set through mechanical vibration, so that the granular material in the multi-layer standard sieve screen for grading and screening. When working, the sample is placed on the top screen frame, the equipment starts to produce uniform vibration or horizontal oscillation, prompting the material in the sieve surface continuous movement. Particles smaller than the size of the sieve hole fall down layer by layer, while particles larger than the sieve hole remain on the corresponding layer, and ultimately realize the accurate classification according to the particle size.

After sieving, by weighing the residual material in each layer of the screen, the particle size distribution curve of sand and gravel can be calculated, so as to assess whether the grading meets the engineering requirements.

Videos

Standard Test Sieve Sizes

Sand test sieves are used for particle size analysis in various industries, including construction, mining, pharmaceuticals, and food processing. Standard sieve sizes are defined by international and national standards such as ISO 3310, ASTM E11, and GB/T 6003 (China). Test sieves are typically made of stainless steel (brass or brass frame options available) and come in standard diameters such as 200mm (8″), 300mm (12″), and 450mm (18″). The follow are common test sieve sizes table(mm & Mesh):

| Sieve Opening (mm) | Approx. Mesh (per inch) | Typical Application |

|---|---|---|

| 9.50 mm | 2 mesh | Coarse gravel, aggregates |

| 4.75 mm | 4 mesh | Gravel, coarse sand |

| 2.36 mm | 8 mesh | Coarse to medium sand |

| 1.18 mm | 16 mesh | Medium sand |

| 600 μm (0.6 mm) | 30 mesh | Fine sand |

| 300 μm (0.3 mm) | 50 mesh | Very fine sand, silt |

| 150 μm (0.15 mm) | 100 mesh | Fine powders, silt |

| 75 μm (0.075 mm) | 200 mesh | Ultra-fine particles, clay |

Applications

Sand test sieve set is widely used in the following scenarios:

Construction material testing: used to determine the grading of construction sand, gravel and other aggregates, so as to make them meet the proportioning requirements of concrete, mortar and other engineering materials.

Geological and mineral analysis: mainly used in mineral processing, soil research and other fields to analyze the particle size distribution of sand, soil, ore and other materials.

Laboratory research and quality control: used in colleges and universities, scientific research institutions and testing centers to conduct material science research using sand test sieves, so that sand and gravel products comply with national standards.

Road and bridge engineering: testing the particle composition of roadbed filler, asphalt mixture and other materials to optimize the construction ratio.

Water conservancy and environmental protection engineering: analyzing the fineness modulus of materials such as river sand and mechanism sand, and assessing their suitability for use in concrete, filter layers and other applications.

Industrial production: in ceramics, glass, foundry and other industries, used for raw material screening, to ensure the uniformity of product particles.

Sieve Mesh Specifications

| Production Name | Wire Mesh Test Sieve |

| Material | Stainless steel 304, 304L, 316, 316L, brass,custom |

| Frame material | Stainless steel, brass. |

| Surface treatment | Galvanized, electrostatic paint. |

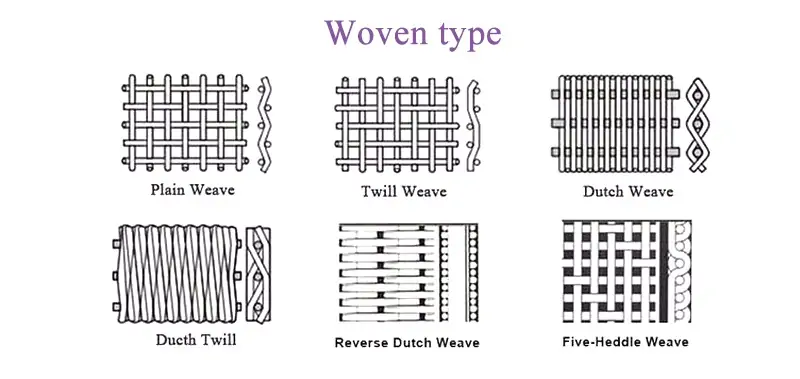

| Production process | Plain woven, perforated holes. |

| Hole shape | Square or round. |

| Common size | 8 “,12″,17.7 .24”, other size can be customized |

| High | 2″ .4″.other size can be customized |

| Aperture | From 1 micron to 50mm both can be customized |

| Applications | Mainly used for flour, beans, sand,medicine and lab material separation |

| Packing | The use of wooden packaging can also be packaged according to specific needs |

| Standard | ASTM E323-11, ASTM E11-16, E161-12, ISO 565-1990, ISO 3310-1, ISO 3310-2, ISO 3310-3, ISO 2591-1, GB/T 6003. |

| Feature | High strength, not easy to be damaged. Lightweight structure, easy to operate and transport. Anti-corrosion, high temperature resistance, anti acid and alkali. Suitable for all kinds of powders and particles. Sieving can be done in a dry and humid environment. Strong and durable with longer lifespan and free maintenance. |

| Application | sieve soil, grain, flour, coffee powder or used for particle size analysis:Garden. Laboratory. Home. Metallurgy industry. Construction industry. Quality inspection department. |

Product Show

Features

High precision screen design

The screen specification covers the whole particle size range from 150mm to 5μm (0.005mm), and the screening precision is strictly tested by the authoritative technical supervisory organization.

High quality SS304 stainless steel material

The screen frame is made of food-grade SS304 stainless steel, with anti-rust, non-magnetic, high-precision characteristics. 0.6mm thickened box structure, strong sealing, no leakage of material seepage phenomenon, long-term use without deformation, durable.

High temperature welding process

Sieve mesh and frame adopt high-temperature welding technology, which can withstand the extreme environment of 400℃, and is suitable for screening all kinds of organic/inorganic solutions. The one-piece molding structure has no seams, completely eliminating the problem of material entrapment and providing high purity of screening.

Global standardization

Support 400/300/200mm and other international common size customization, compatible with the standard sieve frame specifications. Widely used in medicine, food, super-hard materials (diamond, etc.), chemical industry, metallurgy and other high-end fields, to meet the demand for precision screening in various industries.