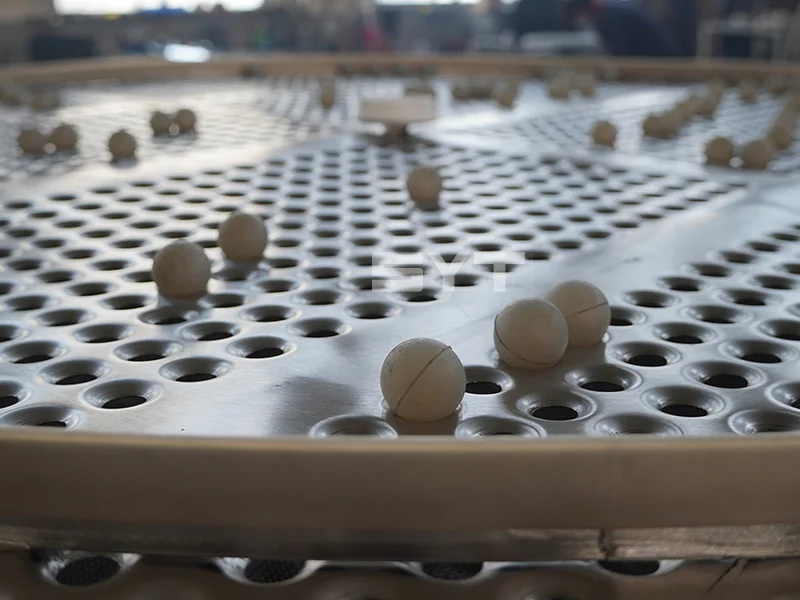

The screen cleaning ball is an indispensable small part of the vibro sifter. Its function is to hit the screen by cyclically hopping back and forth between the rotary vibrating screen and the pallet, imitating the manual tapping of the screen surface, so that the material adhering to the screen surface can be separated from the screen. Avoid blocking the screen from affecting the screening output and accuracy.

- Material: Natural rubber, silicone, polyurethane

- Customizable materials: Food-grade silicone, high-abrasion-resistant polyurethane, oil-resistant, temperature-resistant specialty rubber

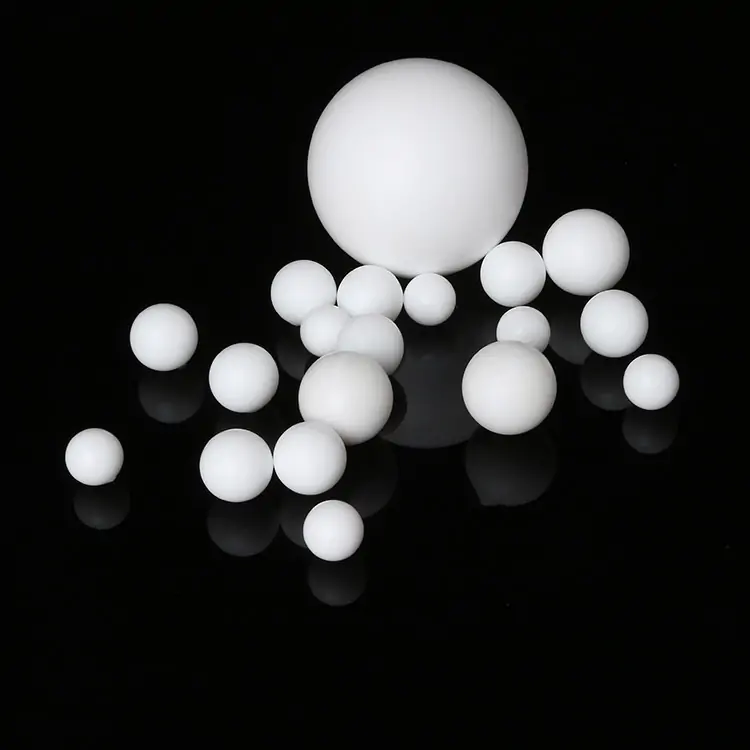

- Diameter: Φ15mm – Φ60mm Customizable to any size

- Physical properties: Rebound elasticity ≥45%, hardness 40-90 Shore A, corrosion-resistant, high-temperature-resistant, abrasion-resistant

- Structure: Solid, hollow

- Color: Black, white, any color

Screen Cleaning Balls Size and Material

Screen Cleaning Balls Size

Screen Cleaning Balls have various diameter specifications, such as Φ10, Φ15, Φ20, Φ25, Φ28, Φ30, Φ40, Φ50, Φ60, etc. Among them, Φ25 and Φ28 are commonly used specifications, while Φ40, Φ50, and Φ60 are mainly used in mining vibrating screens. middle.Bouncing Balls Size

Based on your screening requirements, we offer custom sizing. We can provide precision custom sizing (Φ15-60mm±0.5mm) to ensure a perfect fit with the screen holes and efficient anti-clogging. Simply provide the screen machine model and material characteristics, and we will customize a dedicated bouncing ball solution for you to solve the problem of screen clogging!

Screen Cleaning Balls Material

Professional customized vibrating screen accessories: We provide precise material selection solutions based on working conditions. We support customized material performance to precisely match your working conditions!

The following are commonly used materials for reference:

| Property | 01 NBR (Nitrile) | 02 NR (Natural Rubber) | 03 SIL (Silicone) | 04 EPDM | 05 FKM (Fluorocarbon) | 06 IIR (Butyl) | 07 CR (Neoprene) |

|---|---|---|---|---|---|---|---|

| Wear Resistance | ★★★☆ (Medium) | ★★☆☆ (Low) | ★★☆☆ (Moderate) | ★★★☆ (Good) | ★★★★ (Excellent) | ★★☆☆ (Low) | ★★★☆ (Good) |

| Impact Resistance | ★★★☆ (Good) | ★★★★ (Excellent) | ★★☆☆ (Brittle) | ★★★☆ (Good) | ★★☆☆ (Moderate) | ★★★★ (High Damping) | ★★★☆ (Good) |

| Temp. Range | -30℃~120℃ | -50℃~80℃ | -60℃~230℃ | -50℃~150℃ | -20℃~200℃ | -40℃~130℃ | -40℃~120℃ |

| Media Resistance | Mineral oil ● Grease ● Solvents ○ | Water ● Weak alkali ● Oils ○ | Water ● Acid/alkali ● Oils ● | Water ● Refrigerants ● Ozone ● | Acids ● Alkalis ● Solvents ● | Chemicals ● Gas permeation ○ | Ozone ● Oils ○ Weak acids ● |

| Typical Applications | Coal/ore screening | Grain/building materials | Food/pharmaceuticals | Humid environments | Chemical/high-temp materials | High damping required | General-purpose screening |

Types Of Screen Cleaning Balls

When choosing a bouncing ball, we should fully consider its material to meet performance needs under different conditions.

1. Silicone Gel Ball

Silicone bouncing balls have good elasticity and wear resistance and are not easy to fall. It is widely used in the screening of food, medicine, and other materials.

2. Rubber Bouncing Ball

Natural rubber bouncing balls are suitable for general material screening processes.

3. PTFE Bouncing Ball

PTFE bouncing balls can be soaked in oil and are specially used for screening oily liquid materials.

Function Of The Screen Cleaning Balls

The bouncing ball impacts the screen mesh by moving up and down in the vibrating screen machine, thereby preventing or reducing clogging. The screen mesh of the vibratory screen is an important component of the vibrating screen. There are bouncing balls cleverly installed between the screen mesh and the mother mesh. These bouncing balls can weaken the adhesion of materials on the mesh through their unique impact effect and achieve a clean screen. The function of the net is to improve the efficiency of materials passing through the net.

Custom Screen Cleaning Balls

To provide the most suitable screen cleaning balls for your vibrating screen, please provide the following customised parameters:

- Screen model/size: Vibrating screen brand and screen frame inner diameter

- Screen mesh size: Screen mesh count or millimeter size

- Material characteristics: Material name, viscosity, temperature

- Operating conditions: Operating temperature (maximum value), anti-static/food grade certification requirements (such as FDA), wear resistance grade requirements

- Existing issues: Core pain points to be addressed