Container Loading Belt Conveyor is a kind of mechanical equipment for conveying bulk materials, combining the functions of hopper and rubber conveyor belt, which can efficiently and flexibly accomplish the tasks of loading, conveying and unloading materials. It is widely used in mining, harbor,

Model: SYP

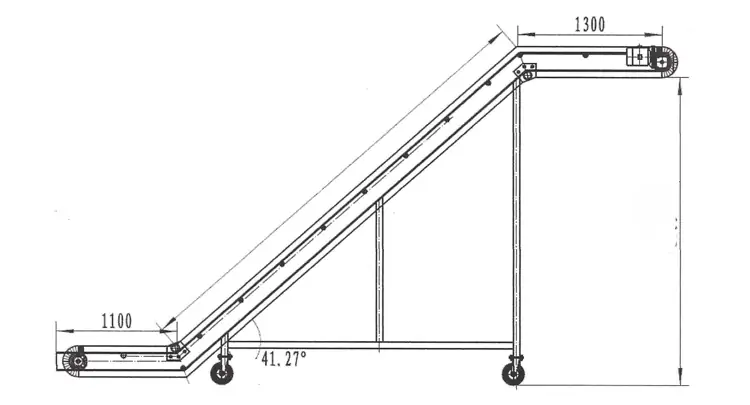

Conveying Angle: 0~30°

Conveyor Length: 5~30 m

Belt Width: 400mm~2000mm

Belt Material: Rubber, PVC, PU

Belt Speed: 0.5-2.0m/s

Height: Adjustable

Container Loading Belt Conveyor Introduction

Container Loading Belt Conveyor is a kind of mechanical equipment for conveying bulk materials, combining the functions of hopper and rubber conveyor belt, which can efficiently and flexibly accomplish the tasks of loading, conveying and unloading materials. It is widely used in mining, harbor, agriculture, construction and other fields, and is suitable for handling many kinds of bulk materials such as coal, ore, grain, sand and gravel.

Mobile Conveyor Belt Working Principle

The material enters the mobile conveyor belt through the hopper, and the drive device drives the rubber conveyor belt to run, conveying the material from the hopper end to the target position. The speed and direction of the conveyor belt can be adjusted by the control system to meet different operational requirements. The mobile device enables the equipment to be quickly transferred to a new working place to improve the working efficiency.

Structures

The mobile conveyor belt is a multi-functional and highly efficient material handling system consisting of several key structural components such as conveyor belts, hoppers, drives, Idlers and Rollers, frames and chassis, control systems and discharge ends. The functional characteristics of each component are as follows:

- Conveyor Belt: The core component, typically made of durable rubber or reinforced material, designed to carry and transport various types of bulk goods.

- Hopper: Located at the feeding end, the hopper collects and directs materials onto the conveyor belt, ensuring a controlled and consistent flow.

- Drive Unit: Comprising an electric motor, gearbox, and drive pulley, this unit provides the necessary power to move the conveyor belt.

- Idlers and Rollers: These support the conveyor belt and ensure smooth movement, reducing friction and wear.

- Frame and Chassis: A sturdy metal framework that supports the entire system, often equipped with wheels or tracks for mobility.

- Control System: Includes switches, sensors, and control panels to regulate speed, direction, and operational efficiency.

- Discharge End: The endpoint where materials are unloaded, often adjustable to direct the flow to specific locations.

Specification

| Item | DY-400 | DY-500 | DY-650 | DY-800 | DY-1000 | |

| Length of machine(m) | 3~20 | |||||

| Belt width(m) | 400 | 500 | 650 | 800 | 1000 | |

| Belt speed(m) | 0.4~1.25 | |||||

| Conveying height | 6.52 | |||||

| Conveying capacity | (m3/h) | 60 | 120 | 220 | 500 | 1000 |

| (t/h) | 40 | 80 | 150 | 200 | 300 | |

| dip angle(°) | 0°~18° | |||||

| Electric roller | Model | DY | DY | DY | DY | DY |

| Power(kw) | 2.2 | 2.2 | 3.0 | 4.0 | 7.5 | |

Customized conveying solutions – to meet your unique needs

Please provide the following information, and our professional team will design an efficient and reliable customized conveying solution for you. Contact us now to get a personalized quote and technical support!

- What is your capacity demand?

- What materials do you need to convey?

- What is the conveying length and belt width?

- Do you need height adjustment function?

- What are the conveying angle requirements?

Get a Quote

Application

The Container Loading Belt Conveyor is a movable, multifunctional and efficient material conveying equipment, mainly used for loading, transferring and unloading bulk materials. It is widely used in mining, agriculture, ports, construction and industrial production. The following are the main application industries and scenarios:

- Mining industry: used for loading and transferring materials such as coal, ore, sand and gravel. The equipment has strong wear resistance and can adapt to harsh environments to achieve efficient and continuous material transportation.

- Agricultural field: suitable for transporting, loading, and unloading agricultural products such as grains, feed, and fertilizers. The conveyor belt is designed to be gentle to avoid damage to the material and is suitable for handling granular and powdery materials.

- Port terminal: used for loading, unloading and storage of bulk goods (such as coal, ore, and grain). The equipment is flexible and can quickly adapt to the needs of different ships and yards to improve operating efficiency.

- Construction site: used for the transportation of building materials such as sand, gravel, cement and concrete. The structure is strong, adaptable to complex terrain, and supports high-intensity operations.

- Industrial production: used for the transportation of raw materials and finished products in industries such as chemical, metallurgy, and food processing. The material and structure of the conveyor belt can be customized according to the material characteristics to improve safety and meet hygiene standards.