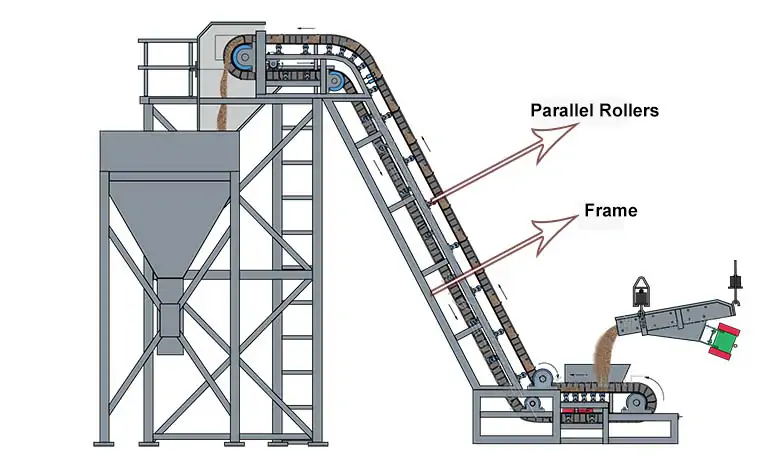

Z type belt conveyor is a kind of continuous conveying equipment innovatively designed according to special working conditions, specially designed to realize large inclination angle and vertical conveying of materials. Compared with the traditional inclined belt conveyor, the Z type belt conveyor adopts unique corrugated sidewall belt structure and sets transverse partitions in the middle of the belt to form a closed conveying unit, so that the materials can be stably conveyed at an inclined angle of 30-90 degrees and are not easy to be scattered.

- Conveying angle: 0-90°

- Belt width: 0.3-1.5 meters

- Conveying length: 6 meters

- Speed: 0.8-4.0 m/s

- Conveying capacity: 28-800 m³/h

- Belt material: food grade PVC, PU, rubber

- Frame material: SUS304 stainless steel/carbon steel

Working principle

Z-type belt conveyor adopts unique combination structure of corrugated baffle and transverse partition to form a closed conveying unit, realizing efficient inclined and vertical conveying of materials. Both sides of the conveyor belt are equipped with retractable rubber wave-shaped vertical baffles, together with equally spaced horizontal partitions, forming a series of continuous box-shaped hopper, so that the material can be stably conveyed at any angle of inclination from 0-90°. The following is its working principle:

When Z type belt conveyor is working, the materials are evenly loaded into the hopper of the lower horizontal section through the controlled feeding device. With the running of the conveyor belt, the specially designed baffle partition structure can wrap the material, effectively preventing spilling and backflow during the inclined or vertical lifting process. When conveying to the upper horizontal section, the hopper automatically turns over with the conveyor belt around the head roller, and the material is naturally discharged under the action of gravity, and the complete discharging can be realized with the vibration cleaning device. The whole conveying process is continuous and smooth, especially suitable for space-constrained occasions requiring large inclination angle or vertical lifting of material conveying needs.

Z Type Conveyor Belt Structures

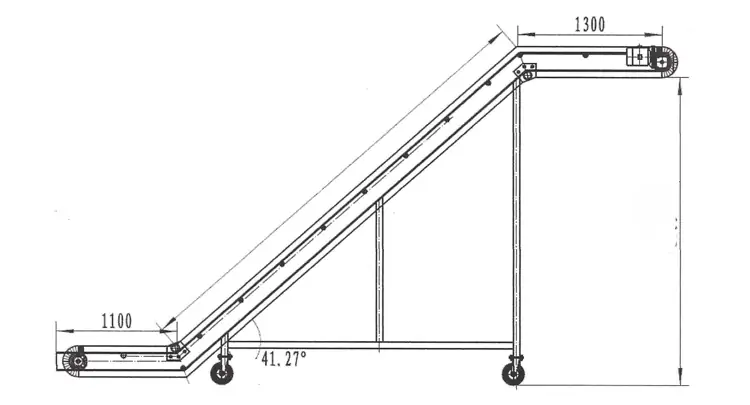

Z type belt conveyor adopts “Z”-shaped layout, which mainly consists of upper horizontal section, inclined section and lower horizontal section, driving device, tensioning device, and sweeper, etc. The following are the functional characteristics of the main components:

- Lower Horizontal Section (loading section): adopts the low intermediate frame legs, with low height of loading opening for easy loading of materials. The height is low, which is convenient for material loading. It can reduce the impact of materials, reduce the wear of conveyor belt, prevent materials from scattering, and improve the loading efficiency; it is suitable for all kinds of bulk materials and packaging parts to feed smoothly.

- Inclined section (climbing section): adopts corrugated baffle conveyor belt + transverse partition to form a closed conveying unit; the legs are adjustable and can be of low, medium or high type to adapt to different inclination angles (30°~90°); when the inclination angle is more than 45°, it is recommended to use the low intermediate frame legs to enhance the stability.

- Upper horizontal section (unloading section): the unloading end adopts head frame of different heights, which can be matched with unloader or guide chute to adapt to a variety of unloading methods; the intermediate frame legs should be coordinated with the height of the head frame to ensure a smooth transition.

- Driving device: adopting frequency conversion motor + reducer to realize stepless speed regulation, energy saving and high efficiency.

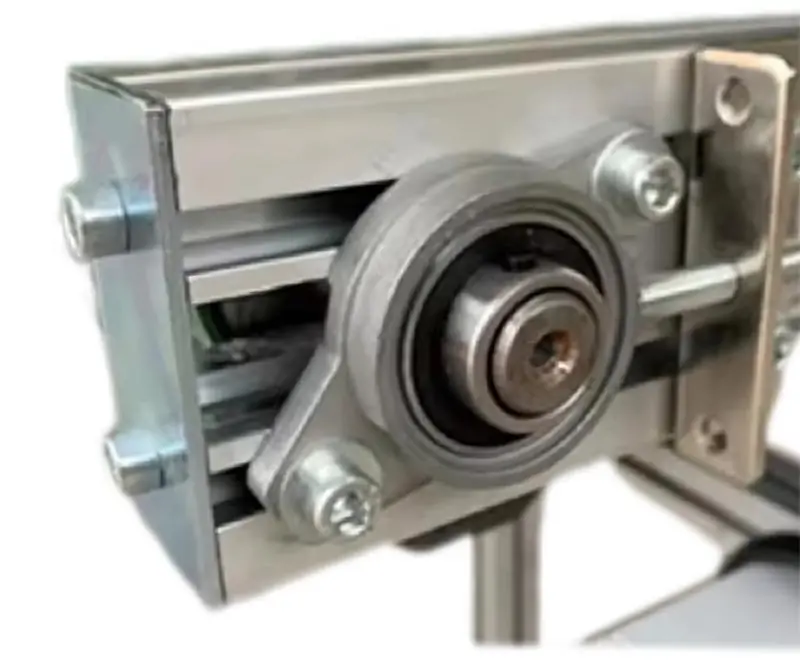

- Tensioning device: automatically adjust the tension of the conveyor belt to prevent slipping or deviation.

- Sweeper: removes the residual material and reduces the maintenance frequency.

Details Show

Electric Machine:

Electric Machine:

Select the high-quality motor and equip it with different power motors according to different loads, ensuring safety and reliability with a two-year warranty. Guide Rail Bracket Round Guide Rail:

Guide Rail Bracket Round Guide Rail:

Adjustable height and width to avoid dropping goods during the conveying Adjusting the Deviation Device:

Adjusting the Deviation Device:

Thickened aluminum block sur

face is Anodizing, fixed with stain

less steel full set of screws, solid

and durable without deformation

and left and right aluminum

blocks can be adjusted for devia

tion Speed Control:

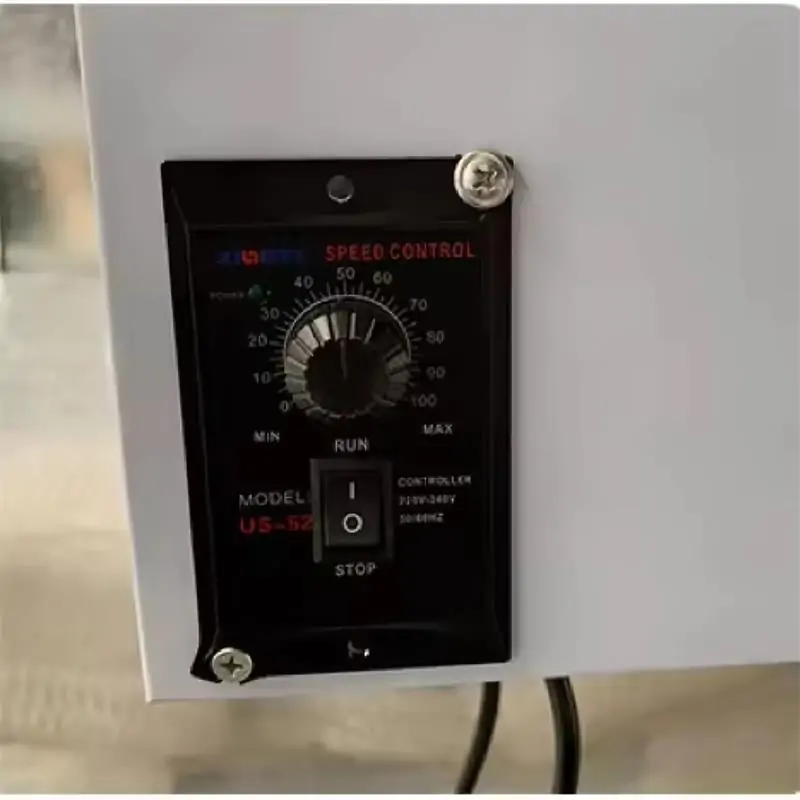

Speed Control:

Adjustable express delivery, specific speed can be adjusted according to customer needs, reliable qualitv, durabilitv. low noise, high product stability, and quality assurance

Specification

| Belt | food grade White PU belt ,with baffle, side walls |

| Structure material | Aluminium, Galvanized Steel, 304/316 Stainless Steel |

| Size | Can be customized on request |

| Motor | 750w (Customized according to your needs) |

| Running Speed | 1-40m/min (Customized according to your needs) |

| Voltage | 110V/220V/380V/415V, 50HZ 60HZ |

| Foot Cup/Casters | Standard quality |

| Weight-bearing | 30-100kg (Customized according to your needs) |

| Install/Assemble service | Online support, Vedio Support |

| Inspection | Provide the photos and video for Confirm before shipping |

Features

- Wear-resistant conveyor belt design: made of wear-resistant PVC material, optional grass stripe belt, stall belt, skirt baffle belt, etc.; with anti-static, corrosion-resistant, easy-to-clean and other characteristics, applicable to food, chemical, pharmaceutical and other industries.

- Large inclination angle and vertical conveying capacity: Climbing section, inclined length, upper and lower platforms can be customized, and the conveying angle can be adjusted from 0° (horizontal) to 90° (vertical) to meet the needs of different working conditions.

- High load bearing and strong adaptability: single machine can continuously convey ≤500kg materials, meeting the needs of small and medium-sized bulk materials and packaging parts. Suitable for humidity, dust, temperature difference and other complex environments.

- Modular structure, intelligent control: support single/multiple accurate feeding, can be matched with PLC or frequency conversion control to realize automatic conveying. It can be seamlessly connected with elevator, sorter, packaging machine and other equipments; provide roller, chain plate, pneumatic interface and other connection methods.

- Stable and reliable, easy maintenance: Spill-proof design: corrugated baffle + spacer structure, zero leakage of materials when climbing or vertical conveying.

- Easy maintenance: modular assembly, easy to disassemble and replace; equipped with automatic tensioning device and cleaning scraper, reducing manual maintenance.

Application

| Industry | Application Scenario | Materials/Usage |

|---|---|---|

| Food Processing | Grain conveying | Rice, wheat, corn, etc. |

| Snack food lifting | Packaged chips, candies, nuts, etc. | |

| Meat processing transfer | Frozen foods, prepared meals vertical transport | |

| Seasoning production | Salt, sugar, MSG and other powdered materials | |

| Chemical Industry | Plastic raw material lifting | PE/PP/PVC particles |

| Fertilizer production | Urea, compound fertilizer particle conveying | |

| Mineral processing | Quartz sand, calcium carbonate dust-proof transport | |

| Hazardous material handling | Explosion-proof design for flammable/explosive materials | |

| Logistics & Warehousing | Parcel sorting | E-commerce package vertical sorting system |

| Warehouse logistics | Boxed goods multi-level shelf access | |

| Port operations | Bulk cargo container loading/unloading | |

| Pharmaceutical Manufacturing | Drug production | Sterile tablet/capsule conveying |

| Medical device transfer | Automated syringe, infusion bottle transport | |

| Biological preparations | Temperature-sensitive material transport | |

| Other Industrial Fields | Building materials | Cement, tiles, glass raw material conveying |

| New energy industry | Lithium battery electrodes, photovoltaic silicon material handling | |

| Automotive manufacturing | Parts assembly line material lifting |