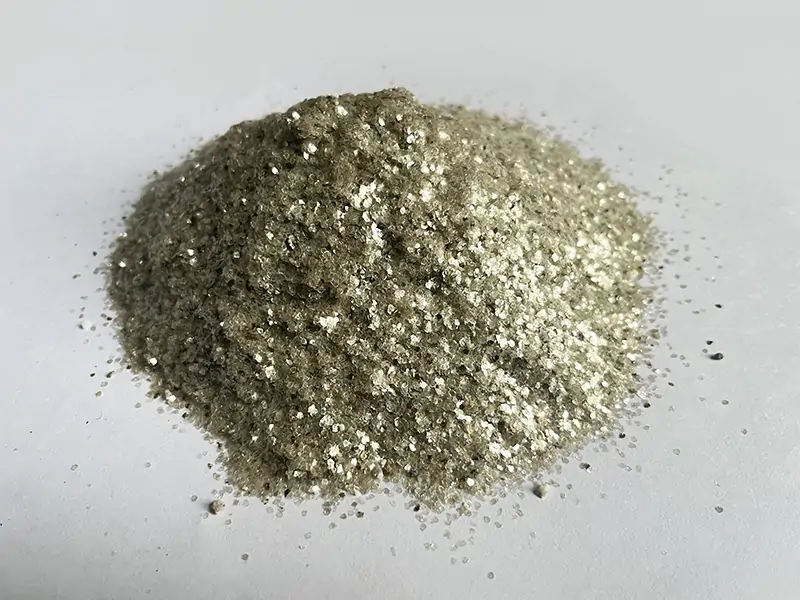

Spice Powder

Spice Powder Sieve Machine solutions

Sieving is a key link in the spice processing industry. The purpose of sieving spice powder is mainly to remove unwanted components such as debris, grease, particles, etc. in the raw materials, so as to obtain clean and pure spice raw materials. How select a spice powder sieving machine directly affects the screening efficiency and product quality. Therefore, the spice screening scheme needs to comprehensively consider multiple factors, such as the aperture of the screen, screening efficiency, screening accuracy, etc.

Spice Powder Sieving Process

- Raw Material Pretreatment: Preliminary inspection and cleaning of the spice powder to be screened to remove large impurities or foreign matter.

- Vibration Screening: The pretreated spice powder is sent to the vibration screening machine and finely screened by the vibration of the screen. During the screening process, large particles and impurities are retained above the screen, and qualified particles fall into the collection device through the screen.

- Grading collection: According to the particle size requirements of the spice powder, a multi-layer screen is set for graded screening. Spice powders of different particle sizes are collected separately to meet the needs of different uses.

- Subsequent processing: The sieved spice powder can be further mixed, seasoned, or packaged.

Sieving Requirements

Material: turmeric, cumin, chili powder, coriander, paprika, etc.

Output: 100kg-2t/h

Mesh size: 30 mesh, 60 mesh, 80 mesh, 100 mesh

Spice Powder Sieving Machine Recommend

For spice sieving, we also have different screening equipment to choose from. Please choose the appropriate vibrating screen according to your needs.

Chili powder Sieving

Recommend Sieve Machine: SY-515 Linear Vibrating Screen

Features: 304 stainless steel materials, high screening efficiency, large processing capacity, and the inclined screen surface design help the chili powder pass through the screen quickly and reduce clogging.

Production: 500-1000kg/hour

Screen mesh: 5mesh, 20mesh

Chili Powder Sieving Videos

Application

Chili powder, pepper powder (including black pepper), star anise, fennel, pepper, mustard, cloves, cinnamon, garlic powder, ginger powder, onion powder, powdered sugar, salt, etc.

Solutions

| Material Name | Screen Size | Equipment Model | Capacity |

|---|---|---|---|

| Pepper powder | 50-60 mesh | SY-1500 | 5 m³/h |

| Chili powder | 40-45 mesh | SY-1200 | 500kg/h |

| Turmeric powder | 60-500 mesh | SY-1000 | 100kg/h |

| Mustard powder | 30-45 mesh | SY-800 | 300-700kg/h |

Features Of Spice Powder Sieve Machine

- Efficient screening: Linear vibration quickly disperses spice powder and improves production efficiency.

- Corrosion resistance: The contact parts are made of 304/316 stainless steel to ensure food safety and equipment life.

- Convenient maintenance: The design is easy to repair and the screen can be quickly replaced to reduce costs.

- Adjustable inclination: Adjust according to the characteristics of the material to optimize the screening effect.

- Low noise: Small amplitude and high-frequency vibration reduce noise pollution.

- Energy saving and high efficiency: Vibration motor drive, low power consumption, and low operating cost.

Related Products

More Solutions

Contact Us for Details and Quotes

Sanyuantang — Focus on Whole Screening and Conveying Solutions 30 years.