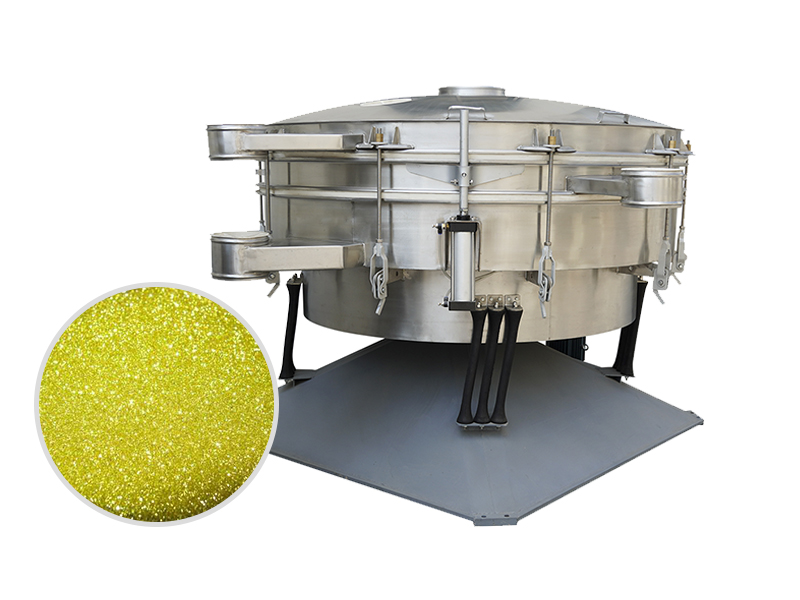

The circular tumbler screen is a material screening device that mimics manual sifting. Compared to conventional vibrating equipment, circular drum screens offer numerous advantages in production lines handling granular or fragile materials, including the preservation of material integrity, high screening efficiency, and a broad applicable particle size range.It is widely used in the food, chemical, metallurgical, pharmaceutical, and carbon industries.

However, during prolonged operation, the circular tumbler screen skew may appear due to component aging or structural damage. Failure to address this skew promptly accelerates equipment deterioration, compromises discharge quality, and shortens service life.

Primary Causes of Circular Tumbler Screen Skew

During actual production operation, the balanced motion of the circular tumbler screen’s body relies on multiple factors working in concert. Deviation in any component can cause asymmetric oscillation of the screen body, resulting in circular tumbler screen skew.

Primary Causes of Circular Tumbler Screen Skew

- Imbalanced eccentric weight distribution: The circular tumbler screen relies on upper and lower eccentric weights for motion. Inconsistent weight values or angles on either side cause uneven oscillation.

- Uneven base or foundation: An unstable installation foundation, loose bolts, or unstable contact between the machine body and the ground can all cause tilting.

- Uneven screen tension: Local variations in tension cause deformation of the screen surface during operation, disrupting the balance of the circular tumbler screen.

- Uneven material feeding: Concentrated material discharge on one side subjects the tumbler screen to prolonged unidirectional impact, resulting in tilting.

- Spring degradation: Spring deterioration causes the circular tumbler screen to lose its dynamic balancing capability.

Hazards of Circular Tumbler Screen Skew

- Reduced screening accuracy: An unbalanced screen surface prevents uniform material distribution, diminishing screening precision.

- Unstable material flow rate: Material buildup on one side and accelerated flow on the other cause deviations in actual screened particle size, affecting final product grading.

- Increased mechanical vibration and noise: Asymmetric forces amplify machine vibration, potentially causing resonance and abnormal noises.

- Accelerated structural component fatigue: Frames, springs, and screen frame connection points endure heightened loads under skew conditions, significantly shortening equipment lifespan.

- Potential for downtime or sudden failures: If unaddressed, skewing progressively worsens, potentially causing component fractures or complete shutdown.

The Solution for Circular Tumbler Screen Skew

- Correct eccentric balancing: Ensure consistent angles for upper and lower eccentric weights, fine-tuning the counterweight ratio based on screening requirements.

- Inspect and reinforce equipment foundation: Tighten anchor bolts. Use a level to verify base horizontal alignment; if foundation settlement occurs, re-level or perform secondary concrete pouring for support platforms.

- Adjust screen mesh tension and inspect frame: Replace damaged or deformed screen frames to ensure uniform circumferential tension across the mesh.

- Optimize feeding methods: Install material buffers or distributors to maintain stable, continuous feed rates and prevent one-sided loading.

- Regularly inspect drive and support components: Periodically maintain fatigue-prone parts and maintain maintenance records.

Installation Manual Of Tumbler Screeners

Conclusion

Concerns about circular tumbler screen skew are unnecessary when you focus on three key areas: purchasing professional components, conducting regular inspections, and seeking expert repairs when issues arise. This approach ensures stable, worry-free production.

If you are interested in our circular tumbler screens, please do not hesitate to contact us. We have thirty years of industry experience, focus on providing you with reliable, labour-saving screening equipment.