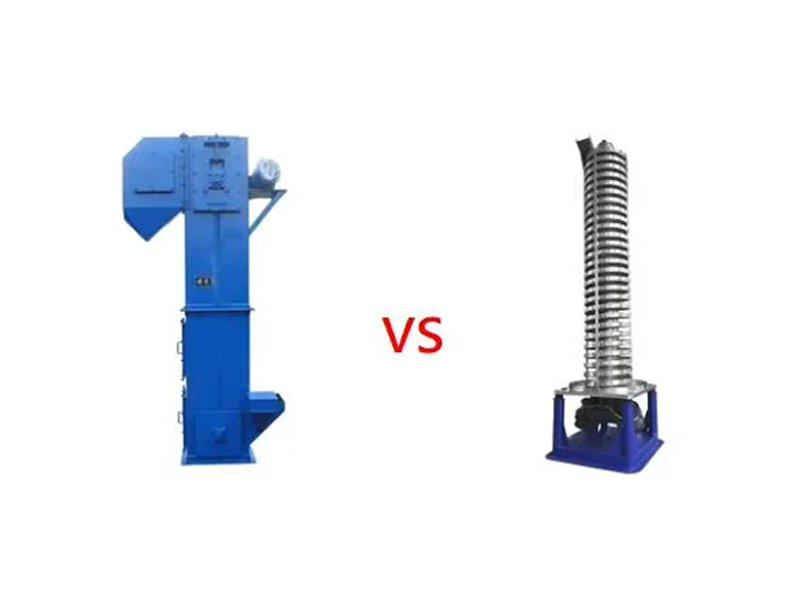

Stainless Steel Vertical Bucket Elevator is a kind of mechanical equipment used for vertical or inclined conveying of bulk materials, the whole machine is made of stainless steel (such as 304/316), which is corrosion-resistant, high-temperature-resistant and rust-resistant. It lifts the materials from low to high place through the hopper fixed on the belt or chain, which is widely used in food, medicine, chemical industry, etc. It is suitable for conveying granular, powdery or small block materials, such as grain, fertilizer, feed and so on. The equipment runs stably and is easy to clean, especially suitable for production environments with high hygiene requirements.

Material: Food grade sus 304 or 316

Conveying capacity: 800m³/h

Lifting height: 40m

Features: Roller dual-speed chain drive, stable transportation, skirt design of feed port, material does not spill.

Application: Food, chemical, pharmaceutical and other industries, suitable for conveying high temperature, corrosive or high hygienic materials.

Price: $3,000~$4500 /Set

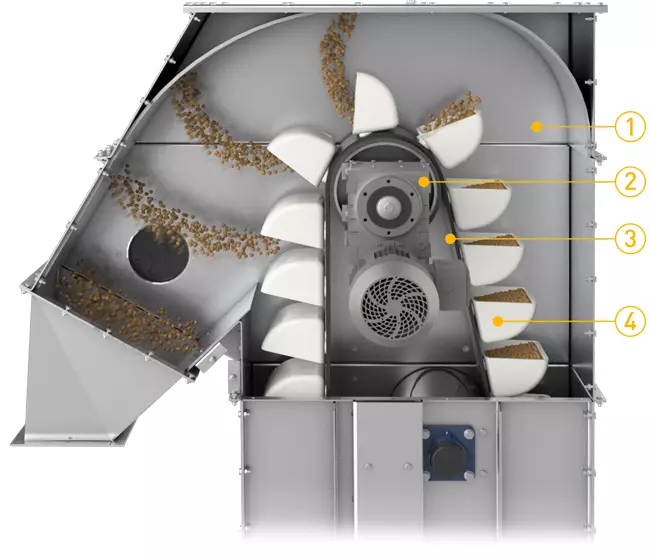

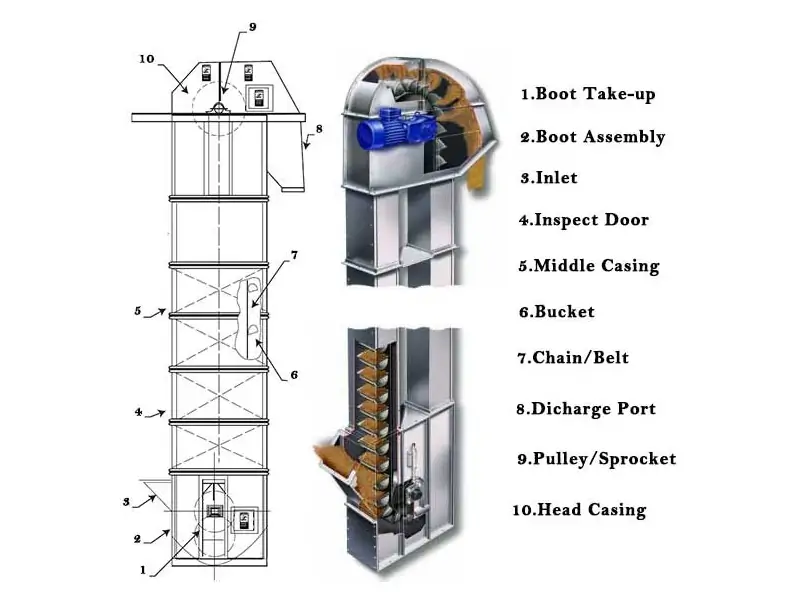

Working principle

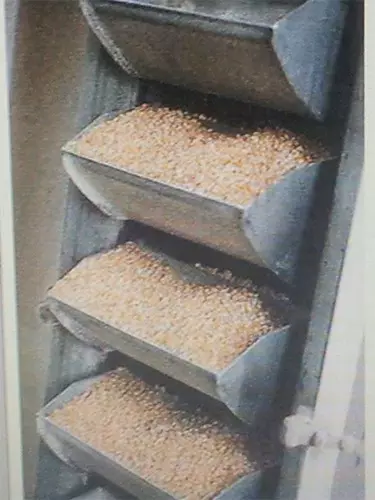

The bucket elevator is mainly composed of shell, driving wheel (head wheel), driven wheel (bottom wheel), traction components (belt or chain) and hopper and other core components. The working principle is as follows: the traction member surrounds the driving wheel and the follower wheel to form a closed circuit, the hopper is uniformly fixed on the traction member according to the preset spacing, and the shell seals the dustpan and the traction belt. The material enters the running hopper through the inlet, and is vertically transported along the elevator cylinder with the traction member to the top driving wheel, where the material is thrown off under the effect of centrifugal force, and finally discharged out of the equipment through the discharge port.

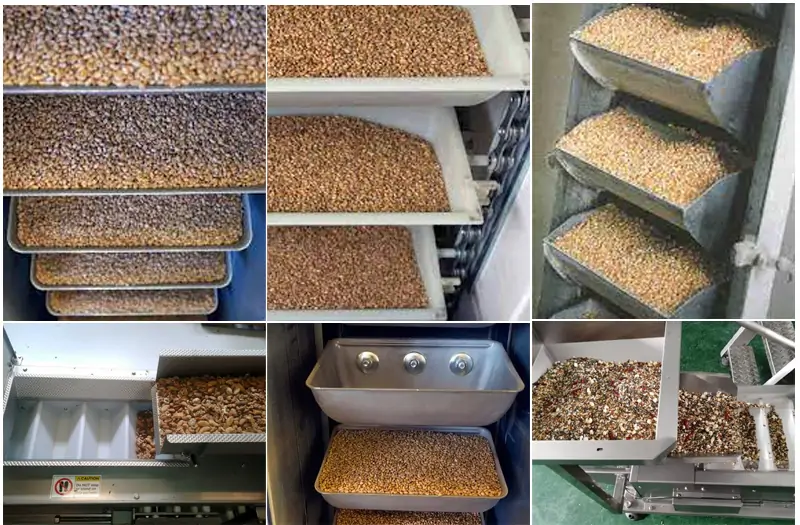

Details Show

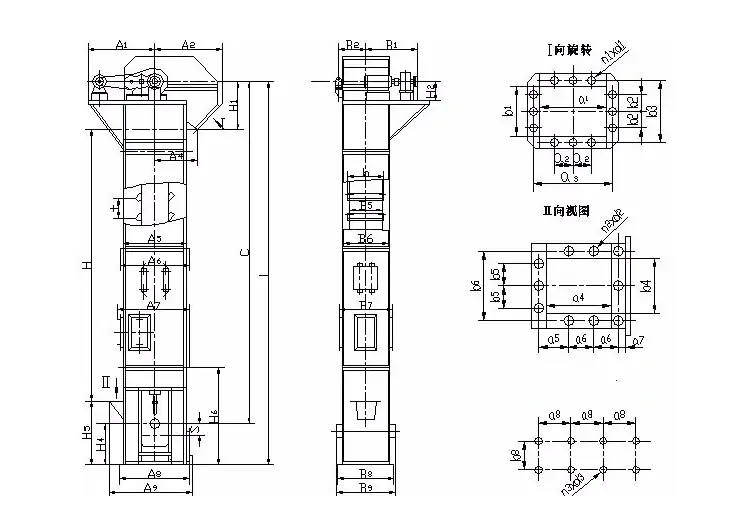

Specifications

| Model | Size of material(mm) | Speed of Bucket (m/s) | Bucket Capacity (L) | Capacity (m3/h) |

|---|---|---|---|---|

| TD-630 | 50-195 | 0.5 | 2.5-501.8 | 15-800 |

| TD-500 | 50-195 | 2.5-501.8 | 15-800 | |

| TD-400 | 50-195 | 2.5-501.8 | 15-800 | |

| TD-315 | 50-195 | 2.5-501.8 | 15-800 | |

| TD-250 | 50-195 | 2.5-501.8 | 15-800 | |

| TD-160 | 50-195 | 2.5-501.8 | 15-800 | |

| More model can be customized | ||||

Customize Vertical Bucket Elevator

The selection of stainless steel vertical bucket elevator depends on the bucket form, bucket speed, material ratio, material properties and the number of buckets. If you need to convey corrosive, high-temperature or high-hygiene materials, a customized stainless steel bucket elevator will be an ideal choice. Please feel free to contact our technical team and we will customize the best solution for you according to your specific needs. Before making a selection, please provide the following basic information:

- Material characteristics (particle size, humidity, temperature, etc.).

- Capacity requirements (tons/hour).

- Site space conditions (conveying height).

Features

- Hygiene and environmental protection, superior material: the whole machine is made of stainless steel (e.g. 304/316), with smooth and easy-to-clean surface, which meets the high standard of hygiene required by the food and pharmaceutical industries, as well as corrosion and rust resistance, suitable for a variety of environments.

- High-efficiency transmission, smooth running: adopting special roller two-speed chain drive system, the power transmission is smooth and reliable, reducing vibration and noise in running.

- Large conveying capacity, high lifting capacity: the conveying capacity is up to 500 m3/hour, and the lifting height is up to 40 meters, which can meet the demand of large-scale production and is applicable to a variety of industrial scenarios.

- Flexible design, customized hopper: the width of the hopper is the same as the inlet, so the material enters smoothly, while the length of the hopper can be customized according to the specific needs, adapting to the conveying requirements of different materials.

- Anti-overflow design, reduce waste: the inlet adopts a unique skirt design, effectively preventing material overflow and avoiding contact with the moving hopper, reducing material loss and environmental pollution.

- Multi-functional feeding, strong adaptability: according to the characteristics of different materials (such as particle size, fluidity, etc.), can be configured with a variety of feeding devices, such as vibrating feeder, screw feeder, etc., to ensure that the material enters the elevator in a uniform and stable manner.

- Compact structure, convenient maintenance: the equipment design is compact, small footprint, while the key components are easy to disassemble and maintain, reducing the cost and time of daily maintenance.

Applications

- Food processing industry: used for vertical conveying of raw materials such as flour, sugar, salt, grain, etc., in line with food hygiene standards.

- Chemical industry: It is suitable for conveying corrosive chemical raw materials, such as fertilizer, soda ash, resin, etc.

- Pharmaceutical industry: It is used for the transportation of pharmaceutical raw materials and intermediates to ensure the cleanliness of materials.

- Metallurgical industry: used in the lifting operation of high temperature materials such as mineral powder and metal powder.

- Environmental protection industry: used for lifting and conveying solid materials in garbage treatment, sewage treatment and other projects.

- Building materials industry: used for vertical conveying of cement, limestone and other building materials.

Vertical Bucket Elevator Manufacturer

We are a professional Stainless Steel Bucket Elevator factory and manufacturer with 30 years of industry experience, always committed to providing customers with comprehensive conveying and screening solutions. With profound technical accumulation and rich experience in customizing production lines, we are able to tailor-make efficient and reliable conveying equipment according to customers’ specific needs, and we are especially good at providing specialized solutions for the food, pharmaceutical, chemical and other industries.

Our stainless steel bucket elevators follow the “Ease Sieve” design concept, which ensures high quality while being easy to disassemble and install, easy to transport, easy to clean and maintain. Whether it’s a small production line or a large industrial project, we offer a one-stop service from design and manufacture to installation and commissioning.

If you have material conveying or screening needs, please feel free to contact our professional team. We will provide you with the best quality solutions with our rich experience, innovative technology and comprehensive service!