Project Overview

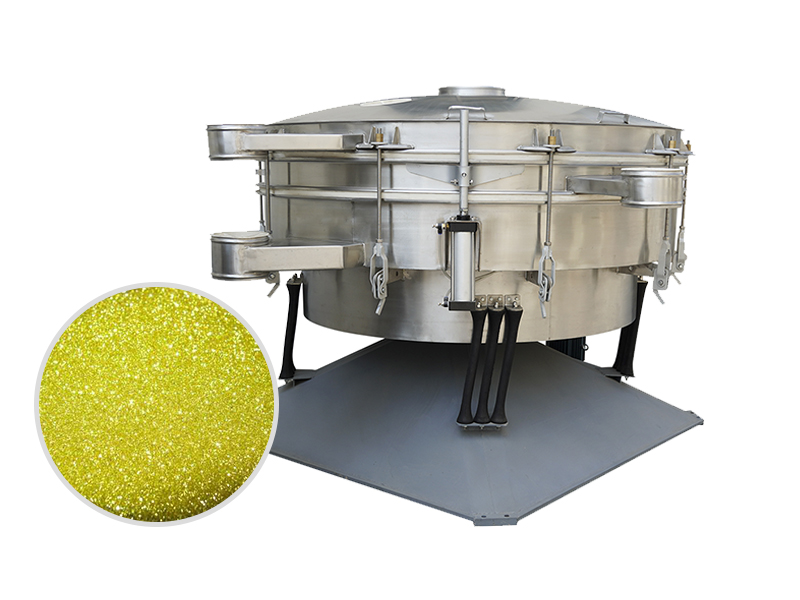

By adopting Sanyuantang Machinery’s tumbler screening machine, a Hebei-based recycled rubber company successfully resolved impurity challenges in tire waste powder. This not only enhanced product quality and production efficiency but also marked a crucial step toward environmental protection and resource recycling.

Project Background

The tire manufacturing process generates substantial amounts of waste powder primarily composed of rubber, fibers, and steel wires. Improper handling not only causes severe environmental pollution but also results in significant waste of reusable resources.

While traditional crushing and grinding processes enable preliminary resource recovery, the presence of impurities and foreign objects in the waste powder poses major obstacles to effective recycling.

Key impacts include:

- Compromised quality stability of recycled rubber products;

- Reduced production efficiency and increased defect rates;

- Accelerated equipment wear and higher maintenance costs.

Thus, efficiently removing impurities and achieving precise powder grading has become an urgent challenge for recycled rubber enterprises.

Custom Solution

Following technical discussions, Sanyuangtang recommended a tumbler screening machine solution. The technical specifications and features are as follows:

Core Equipment: 1600mm diameter tumbler screening machine

Artificial Oscillation Motion: Effectively extends material residence time on the screen mesh, enhancing screening precision.

Multi-layer screen design: Equipped with 20-mesh, 40-mesh, and 60-mesh screens for comprehensive processing—from coarse impurity retention to multi-stage powder classification.

High adaptability: Achieves optimal balance between processing capacity and workshop space constraints.

Solution Highlights:

Production capacity assurance: Equipment delivers stable output of 2 tons/hour, fully meeting the client’s large-scale production demands.

Precise Grading: Rubber powder of varying particle sizes is classified according to different mesh specifications.

Durable Equipment: Minimizes screen clogging and excessive wear, reducing maintenance costs.

Process Flow

Pre-treatment Stage: Tire waste is crushed by a shredder, then ground into fine powder by a mill.

Screening Stage: Powder enters the tumbler screening machine, where material disperses evenly across the screen surface. Impurities are retained, while pure rubber powder is precisely sorted by mesh size.

Product Reuse: The high-purity rubber powder is directly reused in manufacturing industrial products like seals and rubber pads, achieving a closed-loop recycling system for waste materials.

Customer Feedback

Clients highly commend the performance of Sanyuantang’s tumbler screening machine:

“Since implementing this equipment, rubber powder purity has significantly improved, defect rates have dropped markedly, and production efficiency has increased by nearly 30%. Maintenance costs decreased, environmental standards were easily met, achieving genuine cost reduction, efficiency gains, and resource recycling.”