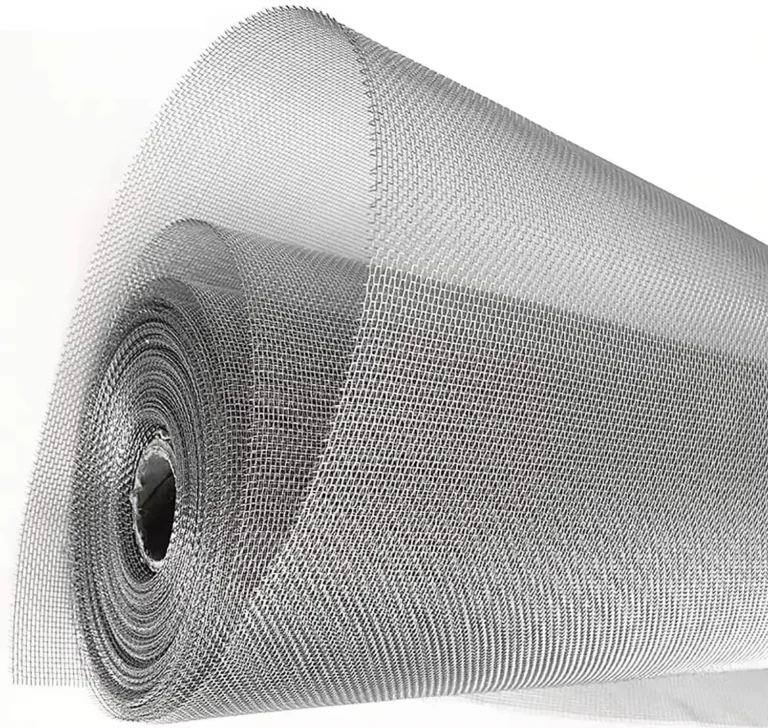

Stainless steel mesh strainers are the most common type of mesh strainer in the vibrating screen industry. They not only effectively remove impurities from materials but also ensure the purity of substances. However, during prolonged use, the fine mesh openings accumulate dust, oil residue, and trapped impurities, gradually clogging the mesh and reducing filtration efficiency. Therefore, we must monitor the condition and cleanliness of the screen mesh.

Why is regular cleaning of the screen mesh necessary?

Regular cleaning of stainless steel mesh screens not only maintains optimal filtration performance but also prevents equipment clogging and damage. Failure to clean for extended periods may result in:

- Significantly reduced filtration speed;

- Increased impurity permeability;

- Heightened equipment load;

Secondary contamination risks in applications such as food processing, pharmaceuticals, or laboratories.

In reality, cleaning mesh screens is straightforward. Below is a detailed guide to cleaning stainless steel mesh screens, along with practical tips to reduce cleaning frequency.

Tools Required Before Cleaning

- Before cleaning stainless steel screens, prepare the following tools:

- Clean water or a hose with a spray nozzle;

- Soft-bristle brush (avoid wire brushes);

- Mild detergent or specialized stainless steel cleaner;

- Protective rubber gloves;

- Small basin or container for soaking.

With these tools ready, let’s proceed to the specific cleaning steps for stainless steel screens.

Cleaning Steps for the Sifter Screen:

1. First, remove the screen and rinse it thoroughly with clean water or blow it clean using a rubber hose. Ensure all corners are thoroughly rinsed until the stainless steel holes are visible or the water runs clear.

2. Soak the stainless steel screen in a specialized stainless steel cleaning solution. Soak the screen for about 10 minutes to allow the cleaning solution to fully break down debris and grime.

3. Clean both the inner and outer surfaces of the stainless steel mesh using a soft-bristled brush. For stubborn stains, gently scrub with a fine-bristled brush. Avoid using metal tools to clean the mesh, as they may scratch the surface and reduce its lifespan. When scrubbing, start from the outer edges and work inward.

4. Soak the stainless steel mesh in clean water and rinse thoroughly to remove all cleaning agents and residues. Alternatively, use compressed air to dry the interior before reinstalling the strainer.

5. To reduce cleaning frequency, remove and clean the strainer after each extended use. This effectively removes accumulated debris. Additionally, placing cleaning aids like scouring pads inside the strainer helps maintain consistent filtration performance over time.

The above outlines the specific steps for cleaning a mesh strainer. Below we recommend several practical tips to reduce cleaning frequency.

How to reduce cleaning frequency for stainless steel mesh strainers?

Regular cleaning is essential, but adopting simple habits can minimize cleaning needs:

- Clean immediately after specialized use: If the strainer filters viscous liquids or construction site water, rinse it for 2 minutes after use to prevent debris from drying onto the mesh.

- Weekly Inspection: Conduct a visual check weekly. If debris accumulation is detected, rinse it off promptly to prevent buildup that becomes harder to clean later.

- Select Appropriate Mesh Size: Using overly fine mesh for large particles causes faster clogging. Consult us to select the optimal mesh size based on your specific filtration needs.

- Cleaning balls: For certain screen cleaning tasks, consider using screen cleaning balls. Their vibrating action reduces clogging rates and lowers cleaning frequency.

Conclusion:

Clean stainless steel screens not only filter more effectively but also last longer. Clogged screens force the entire system to work harder, potentially increasing energy consumption and even causing equipment failure. Furthermore, dirty screens fail to effectively filter impurities, allowing contaminants to mix into water, air, or liquids—rendering the screen installation pointless.

Cleaning stainless steel screen filters is straightforward: rinse, soak, gently scrub, thoroughly rinse, then air-dry. When cleaning, remember to use mild detergents, avoid metal tools, and perform regular maintenance. If you encounter any issues during use, feel free to contact us. Our professional technical team is ready to assist you. Should you require vibrating screen equipment, please also reach out to us. As a leading manufacturer in China’s Vibrating Screen Capital, we bring over 30 years of manufacturing expertise and solution experience to the table.