A vibrating spiral conveyor is a specialized industrial conveying equipment that uses vibrating motion to efficiently and continuously convey materials in a spiral or helical path. Below we will introduce the working principle, structure, design, and different types of vibrating spiral conveyors in detail, please continue reading this article.

vibrating spiral conveyor Structure design

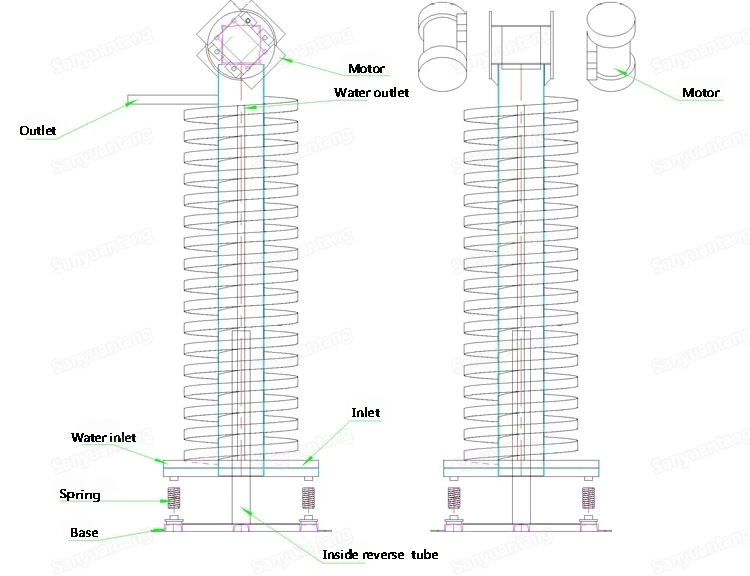

- Spiral track: The conveyor is equipped with a spiral track that runs in an ascending manner on the outside or inside spiral. The track is usually made of stainless steel material to withstand continuous vibrating motion and the weight of the conveyed material.

- Vibration drive: The vibration drive unit is the core of the conveyor and consists of an electric motor, a vibrating mechanism (such as an eccentric weight or an unbalanced rotor) and a drive shaft. By generating vibrating motion, the material is pushed along the spiral track.

- Support structure: The entire conveyor is mounted on a solid support structure to ensure the stability of the equipment operation. The support structure includes rubber pads or other vibration-damping elements to reduce the transmission of noise and vibration to the surrounding environment.

how does a vibrating spiral conveyor work

When the motor of the vibrating drive unit is started, it causes the vibrating mechanism to rotate and generate repeated oscillating motion, which is then transmitted to the spiral track through the drive shaft, causing the material to be gently pushed upward along the spiral path. The material is subjected to a series of small, rapid movements that simulate the micro-throwing principle, ensuring smooth, continuous conveying. (vibrating spiral conveyor.pdf download)

Vibrating spiral conveyors can handle a wide range of materials, including granules, powders, and small parts. The design of the spiral track and vibrating drive can be customized to the specific characteristics of the material being conveyed.

Vibrating Spiral Conveyor Work Animation

vibrating spiral conveyor types

According to different application requirements, vibrating spiral conveyors have different types and designs. The following are several common types and features of vibrating spiral conveyors:

Standard vertical vibrating spiral conveyor:

Specially designed for vertical material conveying, the reverse arrangement of the unbalanced motor generates a vertical conveying force to push the material along the spiral track. It is widely used in food, pharmaceutical, plastic, chemical and other industries, suitable for conveying granular, powdered and small items. It can be designed and manufactured according to the specific needs of customers, including customization in size, material and conveying capacity. Such as high cleanliness, corrosion resistance or high temperature resistant conveying system.

Enclosed vertical Spiral conveyor:

It has an enclosed spiral track to prevent material leakage or external contamination during conveying. It is particularly suitable for handling sensitive or hazardous materials, such as perishable or perishable products in chemicals, medicines, or food.

Cooling and Drying Vibrating Spiral Conveyors:

In addition to the basic conveying function, they are also equipped with cooling or drying equipment, such as radiators or water/hot oil heating systems. Suitable for materials that need to be cooled or dried during conveying, such as plastic granules, chemicals, or food ingredients.

How to select a suitable vibrating spiral conveyor?

When selecting a vibrating spiral conveyor, the following key factors need to be considered:

- Material characteristics: including material size, shape, density and moisture content.

- Conveying capacity: The required conveying rate or throughput.

- Space constraints: The available space required for installation and operation.

- Environmental conditions: The operating environment, including temperature, humidity and potential contaminants.

- Maintenance and maintenance: The ease of maintenance of the equipment and the required maintenance level.

Conclusion

In summary, a vibrating spiral conveyor operates on the principle of vibration and gravity to move materials along a helical path. By using controlled vibrations, the system creates a consistent flow, gently conveying materials without the risk of damage or clogging. Whether it’s for handling bulk materials, fragile items, or powders, the vibrating spiral conveyor offers several advantages, including space efficiency, minimal wear and tear, and easy integration into existing production lines. If you would like to customize your vibrating spiral conveyor, please feel free to contact our team.

Related Articles

- How To Clean The Spiral Conveying Layer When Changing Materials?

- How To Maintain A Vibrating Spiral Elevator Conveyor?

- Vibrating Spiral Elevator For Cooling Plastic Pellets

- Vertical Vibrating Elevator vs Bucket Elevator: How to choose the right vertical conveying equipment?