Linear Vibrating Screens for Pet Food in Greece

Overview

On May 9, 2022, a Greek customer ordered two linear vibrating screens for pet food in our factory. The Greek By-Products Enterprise is a factory that specializes in refining animal by-products and mainly develops, produces, and sells various feeds. With business development, they want to add a new powder screening machine for sieving meat meals.

Customer Requirement

The main products are pet food meat powder, including bones, hair, powder, etc. The raw material size is about 30mm, and 6mm mesh is usually used. The output wants to be about 4-5 tons per hour.

Linear vibrating screens for pet food Solutions

To meet the needs of our customers, we recommended a pet food vibrating screens to our customers. The linear vibrating screen can meet the multi-layer impurity removal effect that customers want. Each outlet can automatically discharge materials, which is suitable for assembly line operations. It has a simple structure and high output. Suitable for screening and classifying powdery materials. It has a fully enclosed structure, is green and environmentally friendly, and complies with food hygiene standards.

Result

The humidity and particle size of meat powder require relatively high screening equipment requirements while ensuring output. The pet food vibrating screens help to solve these problems very well. They solve the quality problem of screening meat powder and guarantee the output. The customer is very satisfied with our equipment and services.

Why choose the linear vibrating screen?

A linear vibrating screen is highly effective at removing impurities and is mainly used for material classification, washing, dehydration, and medium removal. Many finished products need to screen impurities before packaging. The screen can screen them according to the shape, specific gravity, and particle size of the material.

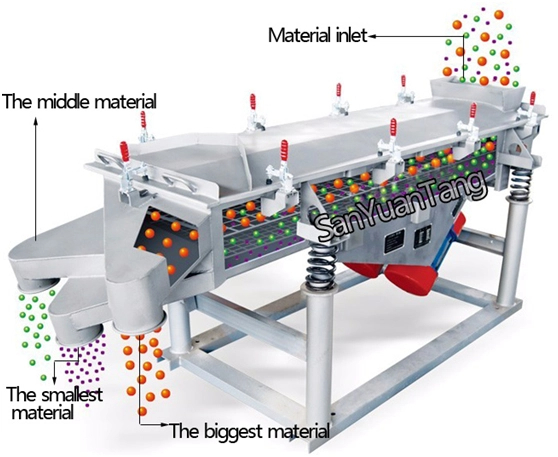

Principle of linear vibrating screen

Linear vibrating screen uses a vibration motor as an exciting force to make the material move up and down on the screen surface in a straight line, thereby screening, filtering and removing impurities.

High screening accuracy

The vibratory screen box for pet food is welded from several steel plates of different thicknesses. It has a certain strength and rigidity when processing materials. In addition, the screen is composed of several screens such as low-carbon steel, brass, bronze, and stainless steel wire, so that the screening accuracy of the whole machine is greatly increased, and there is no dust pollution, which is beneficial to environmental protection.

Large output

The pet food vibrating screens use the vibration motor as the vibration source to make the material thrown up on the screen and move forward linearly at the same time. The material enters the feed port of the screening machine evenly from the feeder, and produces several specifications of screened materials and screened materials through the multi-layer screens, which are discharged from their respective outlets without clogging, and its output is relatively high.

Low cost

The mother net of the linear vibrating screen fully supports the fine net, so the fine net can have a longer life and reduce the use of fine net consumables. If it is used for a long time, it can reduce many production costs, and the pet food vibrating screens can replace a variety of screens, with a long service life, reducing the replacement cycle and reducing the production costs of users.

Easy to operate and maintenance

The linear vibrating screen for pet food adopts a unique screen structure design, which is convenient and quick to replace the screen, and only takes 3-5 minutes, and the screen machine is reasonably designed, exquisite, and easy to assemble, and one person can operate the screen machine. It saves time for customers and reduces labor.