The auger screw feeder hopper is an economical, practical, and convenient feeding equipment, simple structure, easy use, easy maintenance, and easy closed transportation. It is especially suitable for conveying powdery materials that are easy to flow and have poor fluidity, such as flour, soybeans, monosodium glutamate, solid beverages, sugar, coffee, feed, solid medicines, pesticides, dyes, feed, plastic particles, coal powder, muck, cement, and other powdery and granular materials.

Materials: Stainless steel/ Carbon steel

Select angle: Tilt/Vertical

Hopper volume: 70-350 kg

Conveying capacity: 2-22 ㎥/h

Conveying height: 2-70 meters (special requirements can be customized)

Feeding speed: 1 cubic meter/hour

Power supply: 380V/220V

Power: 1.5KW/2.2KW/5.5KW

Weight: 80KG

Working principle

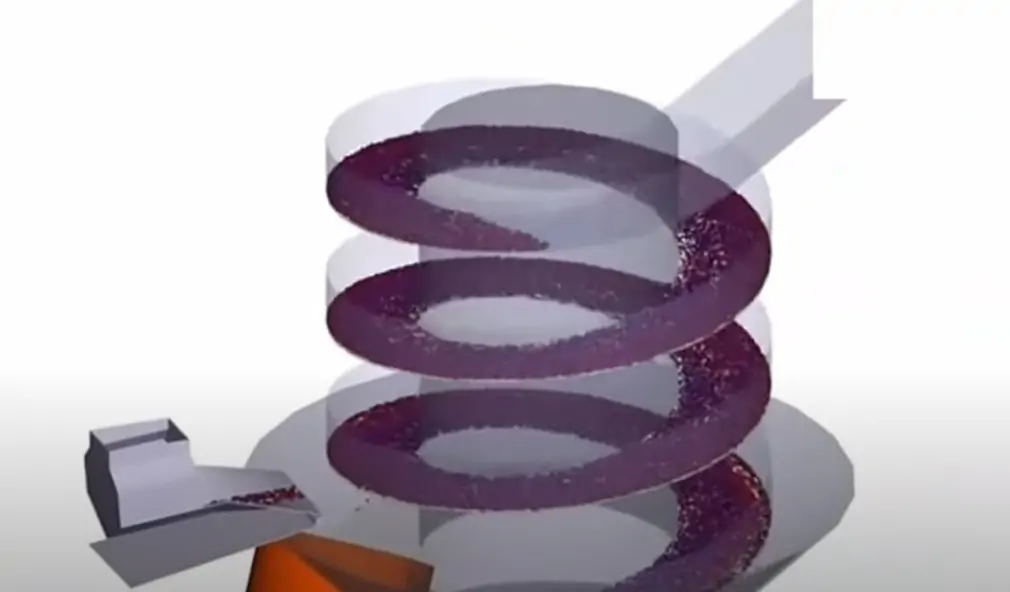

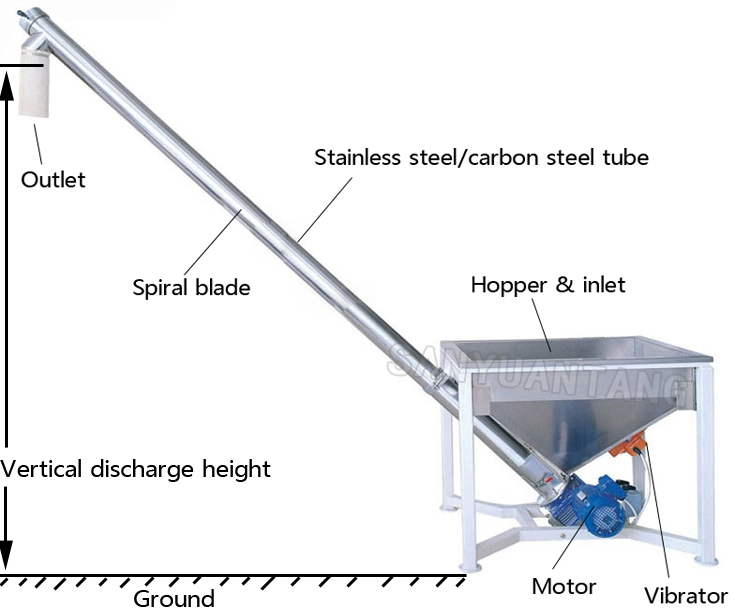

The working principle of the screw feeder hopper is based on the ingenious combination of the screw body and the spiral groove, forming a tight conveying system in the pipeline. When the motor starts and drives the screw body to rotate, the spiral groove rotates synchronously with the material and pushes forward under the action of centrifugal force, thereby realizing continuous and stable conveying of materials.

Working Process

When the screw feeder with hopper is running, the motor drives the screw body to rotate rapidly in the pipeline through the transmission reducer, thereby realizing efficient transportation, precise unloading, and effective processing of materials. The material is injected into the system from the feed port. With the rotation of the screw, it is gradually transported to the discharge port and discharged smoothly after a precise unloading procedure.

Types of Screw Feeder Hopper

Vibrating screw feeders are available in a variety of customizable models. In terms of material, it is mainly divided into two types: stainless steel and carbon steel. In terms of tilt angle, vibrating screw feeders can be divided into horizontal, tilted, and vertical types according to the degree of tilt. In addition, to meet different production needs, buckets of different shapes can also be selected, such as no bucket, square bucket, round bucket, etc. Please read this article for details: How To Choose An Right Inclined Screw Conveyor Model?

Stainless Steel Screw Feeder Hopper

It is mostly used in industries such as food and medicine that have high requirements for a hygienic environment. It is resistant to acid, corrosion, wear, and rust. It is also more convenient to clean up after use.

Carbon Steel Screw Feeder Hopper

It is used in industries where hygiene requirements are not very strict, with low cost, large conveying capacity, good heat insulation effect, no cooling device, and low power consumption.

Horizontal Screw Feeder Hopper

It is used for continuous and uniform conveying of loose materials horizontally or slightly inclined (below 20º), and the conveying distance is generally not more than 70 meters.

Inclined Screw Feeder Hopper

It is used for conveying materials within a range of 60°, and the conveying length can reach 60 meters. It can convey and lift products at the same time, and can directly and automatically convey powder or granular plastic raw materials to silos or other equipment.

Vertical Screw Feeder Hopper

90° vertical upward conveying of materials, the speed is higher than that of ordinary screw conveyors, the lifting height is generally not more than 8 meters, and the floor area is small.

Features of screw feeder hopper

- The feeding is uniform, and the feeding speed can be controlled by installing a variable frequency motor, and the material is not easy to be blocked.

- The feeding motor and the vibration motor can be switched separately to control the vibration amplitude. The system has a time relay. Set the time according to the set amount each time to control the feeding amount.

- The direction of conveying materials is reversible, and materials can be conveyed in two directions at the same time. During the conveying process, mixing, stirring, loosening, heating and cooling can also be completed.

- The silo and conveying pipe are made of stainless steel (the material can be customized according to customer requirements) to ensure that the raw materials are completely pollution-free during the transportation process. 5. The conveying pipeline adopts a closed design, which can effectively prevent dust and effectively isolate materials with high hygiene requirements or strong odor.

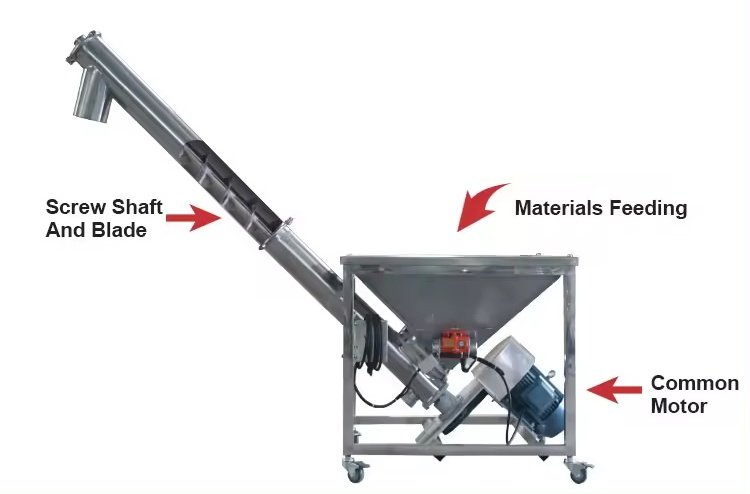

Structure

The screw feeder hopper consists of a discharge device, a precisely designed screw shaft, an efficient feeding mechanism, a sturdy transmission, and other components.

- Vibration motor: The feed motor and vibration motor can be switched separately, and the feeder and vibration amplitude can be independently controlled. The time relay is seamlessly integrated into the system, and the precise time adjustment can be made according to the specific batch size to control the feeding amount.

- Hopper: The design of the hopper should consider reducing the pressure of the feeding screw, and a pressure relief mechanism can be added if necessary to improve the feeding accuracy. Round or square hoppers can be selected for easy feeding. It can be used alone or directly connected to its supporting equipment.

Details

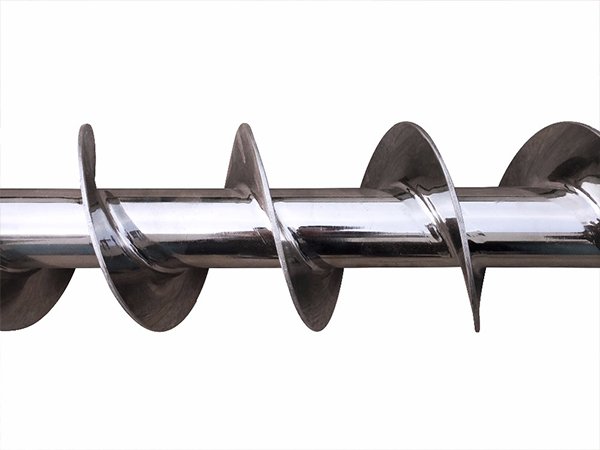

Spiral Shaft:

made of SUS 304 stainless steel, formed in one piece, and the blade angle and spacing can be customized according to needs. Hopper:

Hopper:

The size and shape of the hopper can be customized, usually round or square, and a screen can also be added to prevent debris from entering the hopper. Horizontal Screw Feeder:

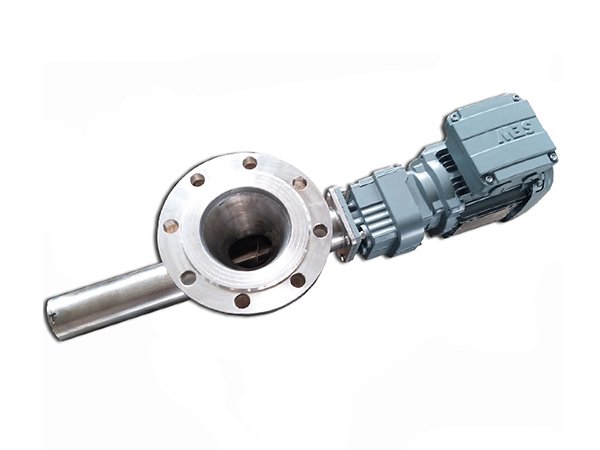

Horizontal Screw Feeder:

can make a horizontal screw feeder, that quickly connects with the machine. Motor:

Motor:

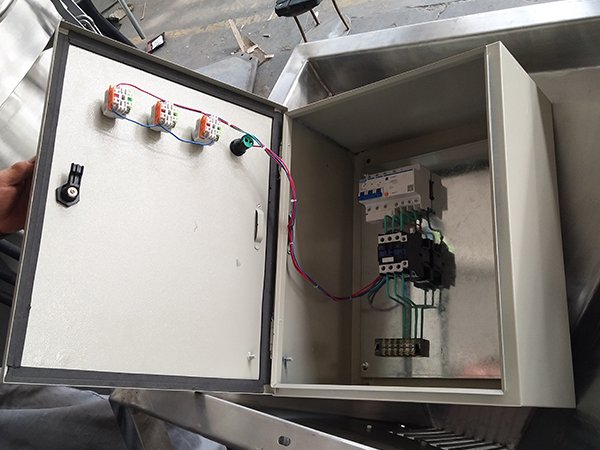

pure copper motor, vibration motor switch control, adjustable amplitude, low noise. Frequency Converter:

Frequency Converter:

Can be equipped with frequency converter for speed regulation

Screw Feeder with Hopper

The screw feeder with hopper is a uniform feeding device based on the principle of the screw conveyor. The device can easily realize the uniform supply of non-sticky powder, granular, and small particle materials from silos and other storage equipment, and the feed particle size is less than 5mm.

Screw feeder with hopper combines conveying, sealing, homogenizing, mixing, and other functions in one, widely used in cement raw material homogenization and silo sealing feeding. It has the advantages of uniform feeding, good sealing, no dust, etc. In addition, the closed design of the conveying pipe of the screw feeder can effectively prevent dust, and effectively isolate the materials with high hygiene requirements or strong odors to ensure that the raw materials are completely free of pollution in the conveying process.

Screw Feeder Hopper

Screw Feeder Hopper Screw Feeder Hopper

Screw Feeder Hopper Screw Feeder Hopper For Flour Conveying

Screw Feeder Hopper For Flour Conveying Screw Feeder with Hopper

Screw Feeder with Hopper U Type Screw Feeder Hopper

U Type Screw Feeder Hopper Carbon Steel Screw Feeder Hopper

Carbon Steel Screw Feeder Hopper

Technical parameters of screw feeder hopper

| Model | Screw diameter(mm) | Screw pitch (mm) | Rotational speed of screw(r/min) | Convey measure(m3/h) | Motor power(kw) | Max dip angle(o ) |

|---|---|---|---|---|---|---|

| LS-100 | 100 | 100 | 140 | 2.2 | 2.2~18.5 | ≤20 |

| LS-125 | 125 | 125 | 125 | 4 | ||

| LS-160 | 160 | 160 | 112 | 8 | ||

| LS-200 | 200 | 200 | 100 | 11 | ||

| LS-250 | 250 | 250 | 90 | 22 | ||

| LS-315 | 315 | 315 | 80 | 34 | ||

| LS-400 | 400 | 355 | 71 | 64 | ||

| LS-500 | 500 | 400 | 63 | 95 | ||

| LS-630 | 630 | 450 | 50 | 150 | ||

| LS-800 | 800 | 500 | 40 | 210 |

Custom screw feeder hopper

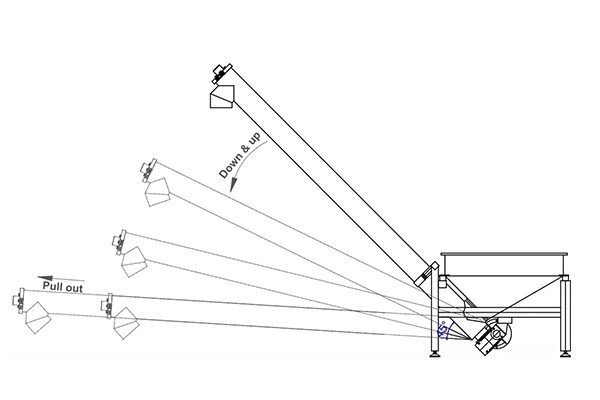

The screw feeder hopper can manufacture hoppers of different diameters, lengths, and inclinations according to user needs. It can also be equipped with a speed-regulating motor according to specific requirements to achieve continuous speed adjustment, thereby achieving precise quantitative feeding goals.

We can also make special customized designs according to your requirements, such as installing universal wheels, designing a discharge port at the bottom, requiring an anti-blocking switch, or other special designs, etc. Please contact us for a customized solution.

1. Selection of Appropriate Model According to Different Production Requirements

For conveying with slight inclination, horizontal orientation, or short distances, the horizontal screw feeder is suitable. Conversely, for vertical conveying or conveying at high inclinations with limited height, the vertical screw feeder is recommended.

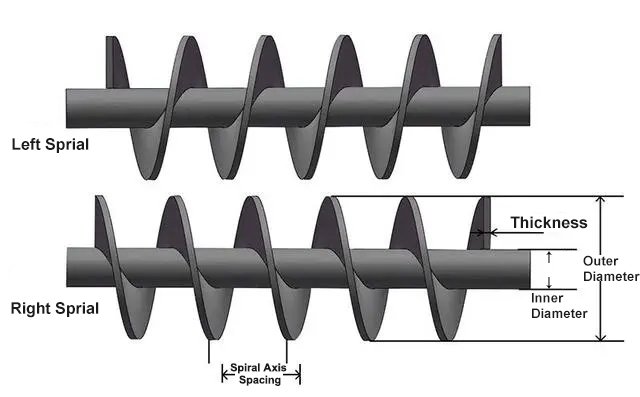

Determination of Screw Blade Form Based on Conveyed Material

- Solid Screw Blades: Primarily used for conveying dry, low-viscosity fine particles or powders such as lime powder, coal powder, etc.

- Ribbon Screw Blades: Ideal for conveying materials with moderate viscosity or in block form, such as sludge.

- Paddle Screw Blades: Designed for conveying materials with toughness or compressibility.

According to the requirements of the process equipment, determine the rotation direction of the spiral blade, the spiral shaft and the direction of rotation, and the combination of the spiral body

The material conveying direction can be determined by determining the position of the conveyor head and tail. The rotation direction of the spiral blade and the direction of the shaft must meet the requirements. If unloading in the middle or at both ends, blades with different rotation directions should be combined to form a spiral body.

Application

Transport Fertilizer

Transport Fertilizer Food Processing

Food Processing Grain Storage

Grain Storage

Professional screw feeder hopper manufacturer

As a professional screw feeder hopper manufacturer, Sanyuantang Machine adheres to 23 years of production experience. Our product line covers various types of screw feeder hoppers to meet the diverse needs of customers, providing free selection and customized drawing design services.

Our factory is equipped with a variety of advanced equipment, including various processing facilities such as lathes, milling machines, installation workshops, spraying workshops, and warehouses. It is also equipped with various processing equipment such as cutting machines, bending machines, and polishing machines to ensure product quality. and production efficiency.

We have a professional design, technology, and service team that can provide customers with a full range of pre-sales services from design, drawing, processing, assembly, painting, quality inspection, and testing to packaging and delivery. In addition, we also provide 12-month quality warranty and lifetime maintenance services to provide customers with comprehensive protection for their subsequent use.