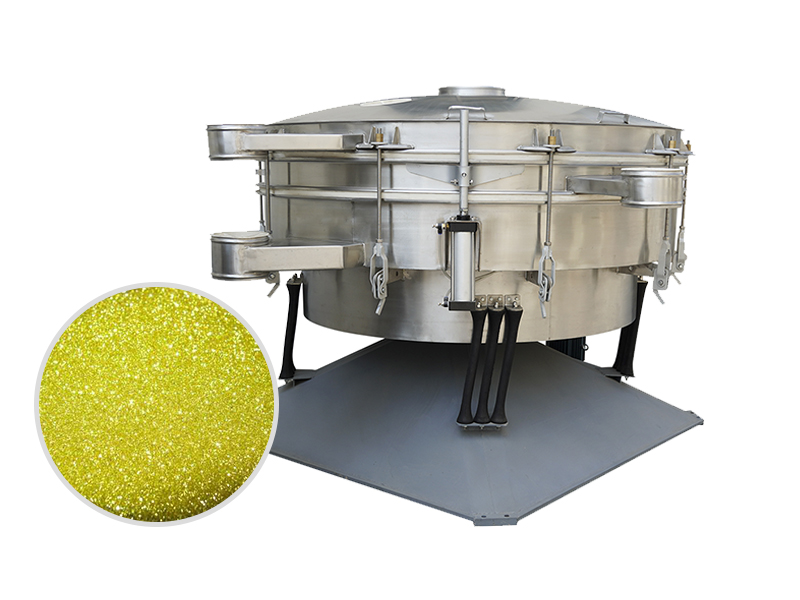

Circular tumbler screen shows significant advantages when screening emery. When screening emery, the tumbler screener can easily complete large-capacity, high-density screening tasks. Its screen life is long, which can reach 5-10 times that of ordinary vibrating screens, thereby reducing maintenance costs and the risk of production interruption. Additionally, the circular tumbler screen delivers high screening precision and efficiency, ensuring optimal screening results for emery.

What is Emery?

Emery, also known as pure, is a colorless crystal and is generally a colorless powder particle. After grinding, it can be used as grinding powder, polishing paper, and the friction surface of grinding wheels and whetstones. It is made by placing sand and the appropriate amount of carbon in an electric furnace to enhance heat. It has high strength and good oxidation resistance and does not deform at high temperatures. It can be used as turbine blades on high-temperature gas turbines, as well as wear-resistant sealing materials. It can also be used as nozzles for rocket tail nozzles and lightweight Bulletproof supplies, etc.

working principle of the circular Tumbler screen

The working principle of the tumbler vibrating screen is to achieve the purpose of screening by simulating manual screening actions and using nonlinear three-dimensional motion to cause the materials to move similar to manual operations. This screening method is especially suitable for spherical, cylindrical, flaky, and even irregular-shaped materials that are easy to block the network. Emery is one of them.

The basic rotary motion of the emery vibrating screen is similar to that of manual screening, the eccentricity is adjustable from 25 to 40mm, and the low-speed V-belt drive is adjustable from 120 to 360rpm. The residence time of each product can be adjusted in the direction of the drive axis through the radial direction and cutting angle of the SY series tumbler screening machine. Thus establishing horizontal and throwing three-dimensional tumbling motions. The resin spreads evenly across the entire screen surface from the center to the outer edge, thereby propagating axially with a helical motion. The fine particles thus complete the whole screening process. The horizontal and vertical acceleration increases with the movement of the particles, and the particles close to the mesh size are successfully separated; the larger particles are transported to the outlet, and the flow is controlled by an adjustable guide at the outlet. The guide is Another factor controlling material residence time. This process is repeated between each sieve layer.

Advantages of Circular Tumbler Screens in Emery Screening

- High Screening Precision: Simulates manual screening motions to ensure thorough tumbling and grading of materials.

- High Efficiency: Low-speed operation minimizes material breakage while boosting output.

- Extended Lifespan: Screen mesh durability is 5-10 times that of conventional vibrating screens, lowering maintenance costs.

- Flexible Parameter Adjustment: Rotational speed, eccentricity, and radial force can be customized based on material properties to meet diverse particle size separation requirements.

Adjust parameters to meet diverse material requirements

The Circular Tumbler Screen can flexibly adjust parameters such as rotational speed, eccentricity, and radial force to alter material residence time and movement trajectory on the screen surface. This adapts to varying material properties and customer screening demands, ensuring optimal screening results. Whether handling fine powders or ultrafine particles, the Circular Tumbler Screen handles them with ease.

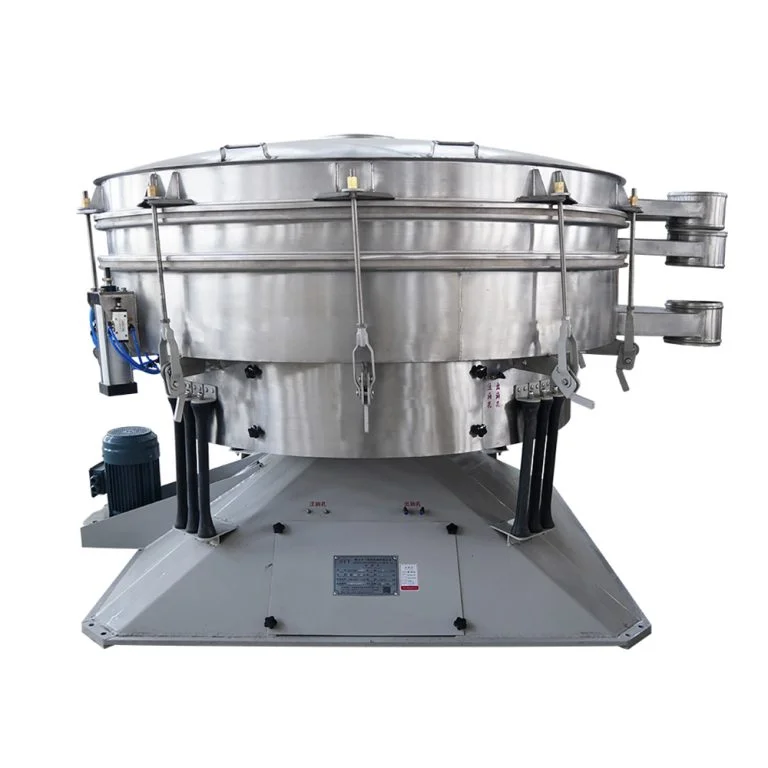

Tumbler Screen for Emery Screening

In order to meet the screening needs of emery of different particle sizes, the rotation speed, eccentricity, radial force, and other parameters of the circular tumbler screener can be flexibly adjusted. This allows the material’s residence time and movement route on the screen surface to be changed, thereby adapting to the physical properties of different materials and customer screening requirements.

We can also customize vibrating screens tailored to your production environment based on your specific operating conditions.

Selecting the Right Swing Tumbler Vibrating Screen Distributor

As a leading manufacturer of conveying equipment and vibrating screens in China, Sanyuantang offers comprehensive solutions including screening machines, conveyors, mixers, and more. If you are seeking high-performance circular tumbler screens or a reliable swing tumbler vibrating screen distributor, contact us for technical support and customized solutions to achieve efficient production and precise screening.

Conclusion

As demonstrated above, the Circular Tumbler Screen has become a critical piece of equipment in Emery screening due to its high precision, efficiency, and longevity. By flexibly adjusting rotational speed, eccentricity, and radial force, it adapts to screening requirements across varying particle sizes and operating conditions. As a company specializing in the R&D and manufacturing of screening and conveying equipment, Sanyuantang not only provides high-performance Circular Tumbler Screens but also offers technical consultation, equipment selection, and engineering support to global users. If you are seeking a reliable swing tumbler vibrating screen distributor, feel free to contact us anytime. We will provide you with efficient, customized screening solutions.

If you need more details or technical support, please feel free to contact us!