In the vast field of industrial production and logistics transportation, various conveyors play an indispensable role. Chain and belt conveyors are two mainstream types, each with its own advantages. The differences in their design principles and application scenarios are crucial for accurate selection. This article aims to analyze the key differences between the two to help you make equipment selections that are more in line with actual needs.

Difference between Chain Conveyor vs Belt Conveyor

| Difference | Chain Conveyor | Belt Conveyor |

|---|---|---|

| Scope of application | Belt conveyor consists of a conveyor belt, driving device, roller, tensioning device, etc. | Belt conveyors are suitable for conveying bulk materials, granular materials, etc. |

| Performance features | Chain conveyors comprise chains, sprockets, guide rails, rollers, etc. | Chain conveyors are suitable for conveying heavy, high-temperature, corrosive materials. |

| Structural features | It has stable operation and simple maintenance and is suitable for long-distance transportation. | Belt conveyor consists of conveyor belt, driving device, roller, tensioning device, etc. |

Belt conveyor

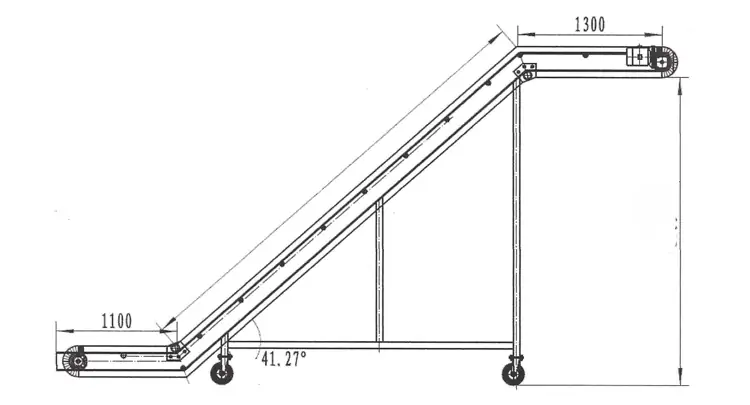

Belt conveyors are known for their simple yet sophisticated structural design, which can easily cope with material transport tasks in horizontal, inclined, and even vertical directions. The core is to support the tough and durable belt surface through rollers. This surface material is diverse, including oil-resistant, high-temperature, and food-grade conveyor belts designed for specific environments, ensuring the safety and efficiency of material transmission.

Advantages:

- Flexible conveying surface: The soft characteristics of the belt conveyor provide a gentle handling environment for vulnerable materials, and the smooth surface design is also convenient for daily cleaning and maintenance.

- Significant cost-effectiveness: Thanks to its simple structure and the use of economical materials such as PVC, belt conveyors perform well in cost control and bring users a higher return on investment.

Disadvantages:

Limited load capacity: When facing highly abrasive or heavy materials, the belt is easily damaged, affecting its service life.

Chain conveyor

The chain plate is mainly a chain plate assembled from stamped chain plates. The chain plate has a very high flatness and is relatively stable during conveying. Various chain plate styles can be customized according to customer requirements. It is currently widely used in conveying machinery in bottling lines, washing lines, and spraying lines. It is a high-demand conveyor belt product.

Advantages:

- The chain plate is very strong and chain-driven for medium and large load conveying. The steel plate is bent to form a hinge, and the hinge and chain are strung together using a support shaft.

- The chains at both ends can be fixed with cotter pins or washers, and cotter pins are used for easy disassembly.

- Chain plates are mainly used in the following aspects: die casting, low-temperature furnaces, iron chip removal, forging, cooling conveyors, recycling and hoists, tunnel quick freezers, etc.

- Excellent heavy-load capacity: The high-strength characteristics of the metal conveyor plate give the chain conveyor excellent load-bearing capacity, meeting the conveying needs of various heavy materials.

- Modular design: The conveyor belt is composed of multiple short-distance metal plates, which is convenient for local repair and replacement, reducing maintenance costs and time.

Disadvantages:

Gap problem: The gap caused by the splicing design may cause blockage when conveying loose materials, affecting the conveying efficiency and equipment life.

Summary

In summary, chain conveyor vs belt conveyors each have their own unique advantages and applicable scenarios. The former is known for its flexibility, economy and easy maintenance, while the latter is the best in heavy load capacity and adaptability to harsh environments. Therefore, when choosing, multiple factors such as material properties, working environment, production efficiency and cost budget should be considered comprehensively to ensure that the selected equipment can maximize the actual needs. For users who are interested in learning more, we sincerely invite you to visit our product page or directly consult online to obtain more comprehensive information and personalized suggestions.

For more information about chain conveyor vs belt conveyors, please email us at info@sanyuantang.com