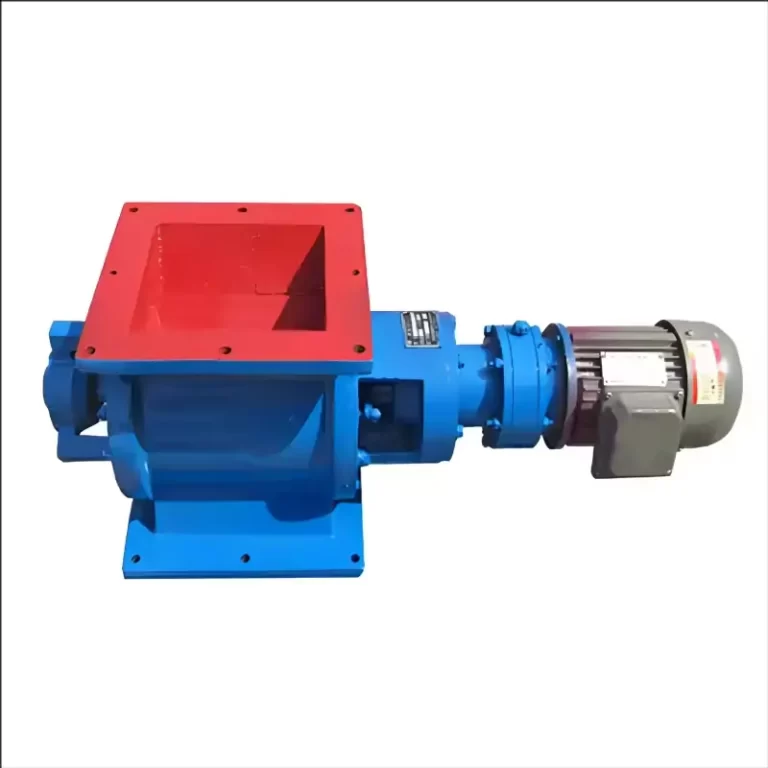

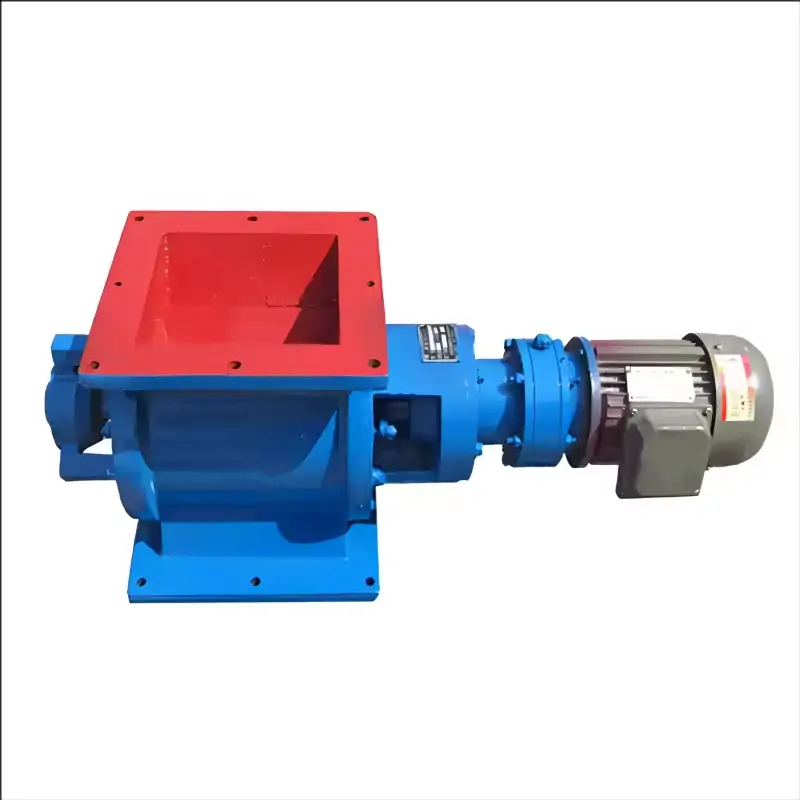

The rigid impeller feeder machine is used to continuously and evenly convey the dry powder or small particle materials in the upper silo to the next level of equipment. It is an accurate quantitative feeding equipment. The rigid impeller feeder is specially designed for continuous and uniform conveying of dust, coal powder and other dry materials with a particle size of less than 10 mm. Its characteristics include excellent blade wear resistance, efficient air locking performance, thorough discharge, smooth connection and compact structure. The elastic impeller feeder adopts an elastic rotor to further improve the sealing performance and ensure uniform feeding of materials.

Models: 300/400/500/630/800/1000

Running speed: 25(rpm)

Applicable materials: Powder, granular, small pieces and other materials

Material Bulk Density: Less than 2.5 (t / m³)

Operating temperature: Less than 250 degrees

Delivery volume: 23-900(m³/h)

Rigid impeller feeders are suitable for conveying and batching systems in power plants, cement plants, chemical plants and other industries. They are used for air locking or quantitative feeding when conveying dry powdered materials. They can also be used for ash discharge under the ash hopper of dust collectors and air preheaters. They have simple structure, stable performance, and convenient operation and maintenance. They are ideal supporting parts in conveying, unloading and batching systems.

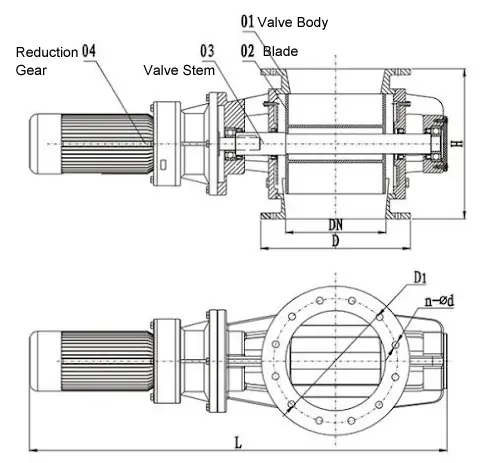

Structures and Working Principle

When the impeller It consists of a rotor with several blades, a housing, a seal, a motor, a reducer, etc.

It is driven by the transmission mechanism to rotate in the machine body, the powder and particle materials dropped from the upper separator (or hopper) enter the impeller cell from the feed port and are sent to the discharge port for discharge as the impeller rotates. In the whole working process, the materials can be fed and discharged continuously and quantitatively.

Details Show

Specifications

| Model | Impeller size(mm) | Capacity per revolution(m³/r·p·m) | Impeller speed(r·p·m) | Theory feeding capacity(m³/h) | Rated feed ability(m³/h) | Motor power(kw) | Reducer Model | Max material size(mm) |

|---|---|---|---|---|---|---|---|---|

| JL200 | 200×200 | 0.005 | 10 | 3 | 2 | 0.75 | BW1 | 30 |

| 19 | 6 | 4 | ||||||

| JL300 | 300×300 | 0.018 | 19 | 20 | 15 | 1.5 | BW2 | 45 |

| 25.5 | 27 | 20 | 2.2 | |||||

| JL400 | 400×400 | 0.045 | 25.5 | 68 | 60 | 3 | BW2 | 50 |

| 35 | 90 | 80 | 4 | |||||

| JL500 | 500×500 | 0.05 | 25 | 75 | 70 | 4 | BW3 | 60 |

| 35 | 105 | 90 | 4 | |||||

| JL630 | 630×600 | 0.09 | 20 | 108 | 98 | 5.5 | BW4 | 75 |

| 28 | 126 | 110 | 5.5 | |||||

| JL1000 | 1000×1000 | 0.11 | 20 | 154 | 132 | 7.5 | BW5 | 110 |

| 28 | 192 | 160 | 7.5 |

Customized According to Different Needs

According to the characteristics, uses and conditions of use of the materials, impeller feeders have various structural types. Its selection depends on the characteristics of the conveyed materials such as particle size, adhesion, temperature, humidity, etc.

Special motors can be configured according to your needs, such as explosion-prooffrequency conversion, Marine motors, etc., in order to meet the special requirementsof users, in the material can also be customized according to user needs, such as hightemperature resistance, corrosion resistance, stainless steel, explosion-proof impeller, etc.

Features

- Flexible impellers are used for smooth operation and good sealing.

- The sealing device and gears are reliable and can be configured according to customer needs.

- Two and a half sealing rings are used at both ends of the impeller, which has a simple structure and is easy to install and replace.

- The discharge port can be designed into different styles such as square or round according to user needs.

- The bearings at both ends of the equipment are designed outside the machine body, which effectively prevents dust from entering the bearings, reduces wear and extends service life.

Application

Stainless steel impeller feeders are widely used, covering multiple industries such as chemical, pharmaceutical, food, and metallurgy. It can not only convey powdered raw materials, but also is suitable for conveying granular materials.

- In the chemical industry, this equipment is often used to convey various chemical raw materials, such as granular plastics and alumina powder.

- In the food industry, it is used to convey various food raw materials such as flour and rice noodles to ensure the efficiency and hygiene of food production.

- In the pharmaceutical field, stainless steel impeller feeders can safely convey various drug raw materials to ensure the hygiene and safety of the production process.

- In the metallurgical industry, stainless steel impeller feeders can convey various metal particles, such as iron powder and copper ore, to meet the high-strength and wear-resistant conveying requirements.