What are Coal Gyratory Vibrating Sieves?

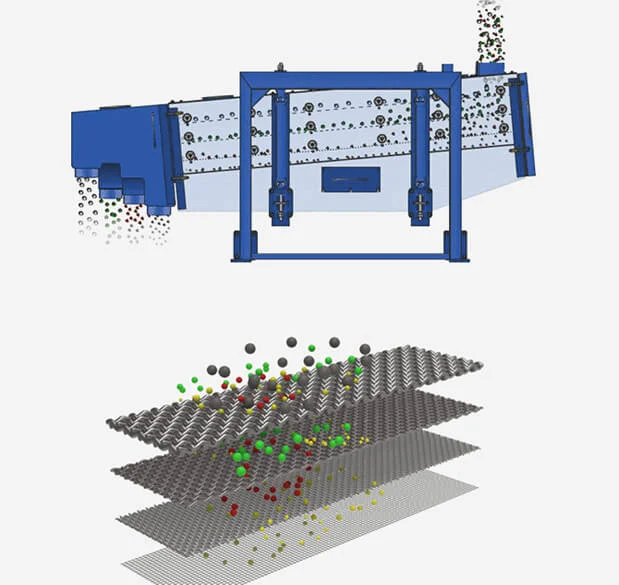

First, we need to understand the primary functions of vibrating screens in the coal industry. Vibrating screens primarily serve functions such as particle size classification, dewatering, de-mediation, and removal of coal slurry impurities in the coal industry. Depending on their specific applications, Coal Gyratory Vibrating Sieves can be categorized into Linear Vibrating Screens and our improved Gyratory Vibrating Sieves. These two types of vibrating screens are the most widely used and frequently applied in the coal industry. They enhance production efficiency and product quality in the coal industry through continuous operational performance. Each type has distinct working principles, structural features, and application scenarios. Let us explore the Coal Gyratory Vibrating Sieve in more detail.

What issues can the Coal Gyratory Vibrating Sieve address in the coal industry?

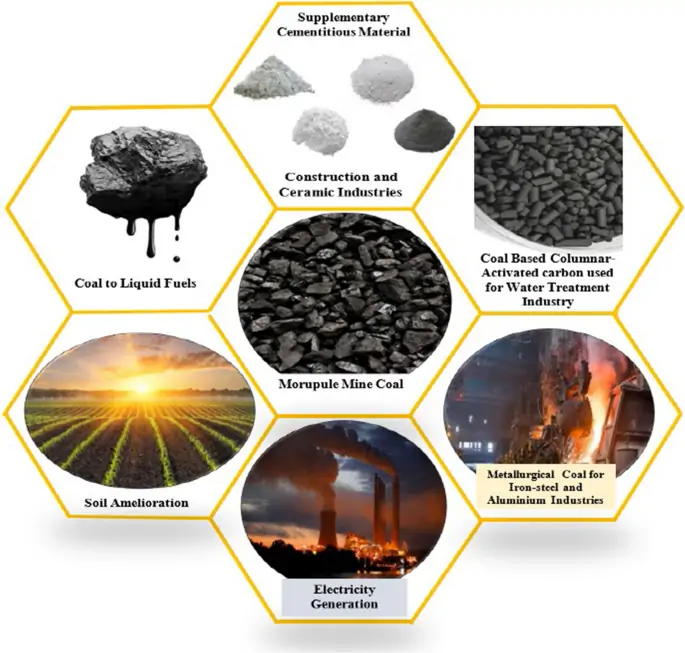

The Coal Gyratory Vibrating Sieve is a key piece of equipment in coal processing, with its performance directly impacting production efficiency and product quality. It primarily addresses the following critical issues:

Uneven product size:

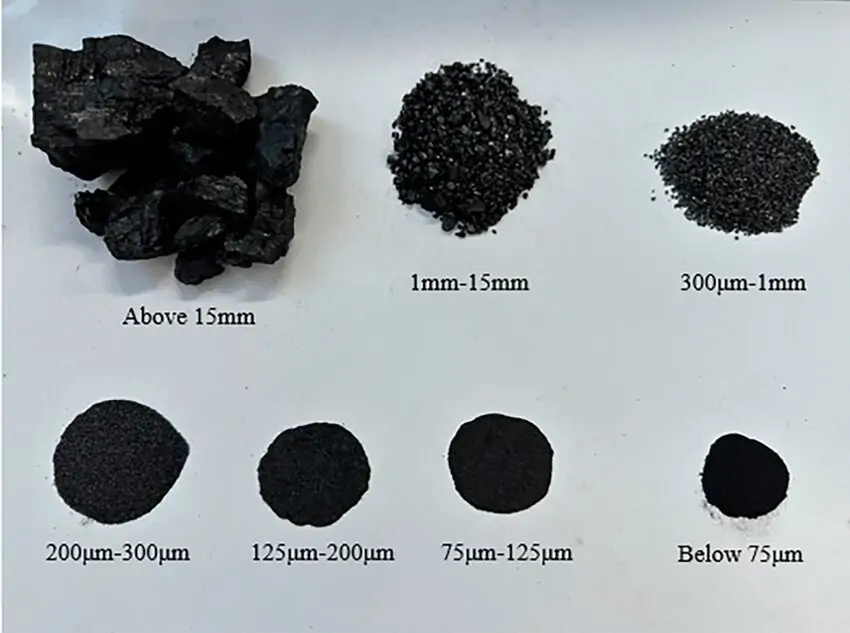

Issue: Raw coal or washed coal particles vary in size, failing to meet the specific particle size requirements of different users such as power plants, coking plants, or subsequent processes.

Solution: The vibrating screen uses screens with different mesh sizes to separate coal into multiple standardized products such as lump coal, seed coal, fine coal, and coal powder.

Low dewatering efficiency:

Issue: After washing, jigging, or flotation, the refined coal, medium coal, and gangue contain a high moisture content, which not only increases transportation costs and affects combustion efficiency but may also lead to frozen vehicles in winter and storage difficulties.

Solution: Dewatering-type screens like the Gyratory Vibrating Sieve utilize strong vibration and screen surface inclination to quickly remove surface moisture from the material, reducing product moisture content.

Magnetite powder recovery:

Issue: In heavy medium coal beneficiation processes, expensive magnetite powder medium can mix into the product or gangue, causing waste and product contamination.

Solution: The Linear Vibrating Screen, in conjunction with water spraying, efficiently separates and recovers magnetite powder from coal concentrate, middlings, and gangue.

Fine Coal Slurry Impurity Interference Issue:

Issue: Coal contains a large amount of fine coal slurry (-0.5mm), which easily clogs screen openings, reduces screening efficiency, affects product purity, and increases the burden on subsequent water treatment.

Solution: The Gyratory Vibrating Sieve effectively screens and removes fine coal slurry, prevents clogging, and improves the quality of the main product.

The Coal Gyratory Vibrating Sieve addresses core challenges in the coal industry—sorting, quality improvement, energy savings, and environmental protection—through effective particle size classification, dewatering, de-mediation, and impurity removal.

Performance Comparison of Coal Gyratory Vibrating Sieves Working Principle, Structural Features, and Application Scenarios

| Feature | Linear Vibrating Screen | Gyratory Vibrating Sieve |

|---|---|---|

| Working Principle | Two vibrating motors generate synchronized counter-rotating forces, driving the screen box in a linear reciprocating motion. Material is thrown forward in a jumping motion. | Mimics manual sieving. A standard motor drives a specially designed exciter to generate 3D elliptical motion (horizontal, vertical, and tilting). |

| Structural Features | Relatively simple and robust structure. Rectangular screen box. Adjustable screen deck angle. Medium vibration intensity. | Square or near-square screen box. High screen mesh utilization (up to 90%+). Complex, smooth acceleration trajectory. |

| Key Advantages | High capacity, suitable for coarse and medium particle sizing. Stable operation, easy maintenance. | High screening accuracy (especially for fines). Blinding resistance. Low noise, lower dynamic load. Reduced material degradation. Extended screen life. |

| Suitable Particle Size Range | Wide range, excels at medium-coarse sizing (>13mm down to 3mm). | Ideal for difficult-to-screen fine, sticky, wet materials (e.g., <6mm, <3mm, <1mm coal slime classification, dewatering, demediuming). Also for high-precision, low-degradation medium sizing. |

| Typical Coal Applications | Raw coal pre-screening, lump coal sizing, coarse medium removal from middlings/reject (primary stage), large particle dewatering. | High-precision fine slime classification/dewatering/demediuming; Screening & dewatering of sticky raw coal or clean coal; Applications demanding long screen life and low noise; Replacement for inefficient traditional screens. |

Linear Vibrating Screens and Gyratory Vibrating Sieves each have distinct advantages, excelling in high-capacity coarse screening, efficient fine particle dewatering and de-mediation, and high-precision processing of difficult-to-screen materials, respectively. The Gyratory Vibrating Sieve, with its improved motion trajectory and structural design, offers superior advantages in screening precision, clogging prevention, screen mesh lifespan, and environmental performance.

If you are unsure which vibrating screen is suitable for your coal application, contact us for professional comparison analysis and customized recommendations!

Which Coal Gyratory Vibrating Sieve is suitable for different scenarios in the coal industry?

The coal processing process is complex. We select the most suitable vibrating screen type based on different process stages and material characteristics:

Raw Coal Workshop:

Scenario: Grading raw coal or unprocessed coal by particle size, such as selling blocks larger than 50mm directly, sending those smaller than 50mm for washing, or conducting inspection screening on crushed materials.

Recommended screen type: Linear Vibrating Screen, which offers high throughput, robust structure, and suitability for medium to coarse particle grading.

Advantages: High throughput, impact resistance, and coarse grading.

Washing and sorting workshop: De-mediuming of products after heavy medium separation

Application: Efficiently separating and recovering heavy medium (magnetite powder) from refined coal, medium coal, and gangue products.

Recommended screen type:

Initial de-mediuming: Linear Vibrating Screen

Final stage high-efficiency de-mediuming: Gyratory Vibrating Sieve offers superior de-mediuming performance, longer screen life, and cleaner medium recovery.

Washing and sorting workshop: Coal concentrate/medium coal dewatering

Scene: Reducing surface moisture in coal concentrate and medium coal products after washing and sorting.

Recommended screen type: Gyratory Vibrating Sieve causes minimal material damage, provides more uniform dewatering, and is suitable for sticky, wet, or fragile coal concentrate.

Advantages: Low moisture output, high processing capacity, and minimal product damage.

Coal Slurry Water Treatment Process: Fine Coal Slurry Classification, Dewatering, and Recovery

Application: Classifying concentrated coal slurry or dewatering coarse coal slurry.

Recommended Screen Type: The Gyratory Vibrating Sieve excels in this application, offering excellent clog resistance, high screening accuracy, and long screen life, making it the optimal choice for fine coal slurry processing (especially sticky fine materials).

Advantages: High-precision grading of fine particles, efficient dewatering, and exceptional anti-blocking performance.

From raw coal preparation to refined coal dewatering, and from de-mediuming to coal slurry recovery, different stages of coal processing have varying performance requirements for the Coal Gyratory Vibrating Sieve. Linear Vibrating Screens and Gyratory Vibrating Sieves cover the core screening equipment throughout the entire process. Especially in the fine coal slurry processing and coal concentrate dewatering stages, where high precision, anti-clogging performance, and long service life are strictly required, the Gyratory Vibrating Sieve is increasingly becoming the preferred upgrade solution for many customers.

If you are seeking the optimal vibrating screen for your coal washing plant, coal preparation plant, or coal slurry recovery facility, contact us immediately to obtain a customized solution!