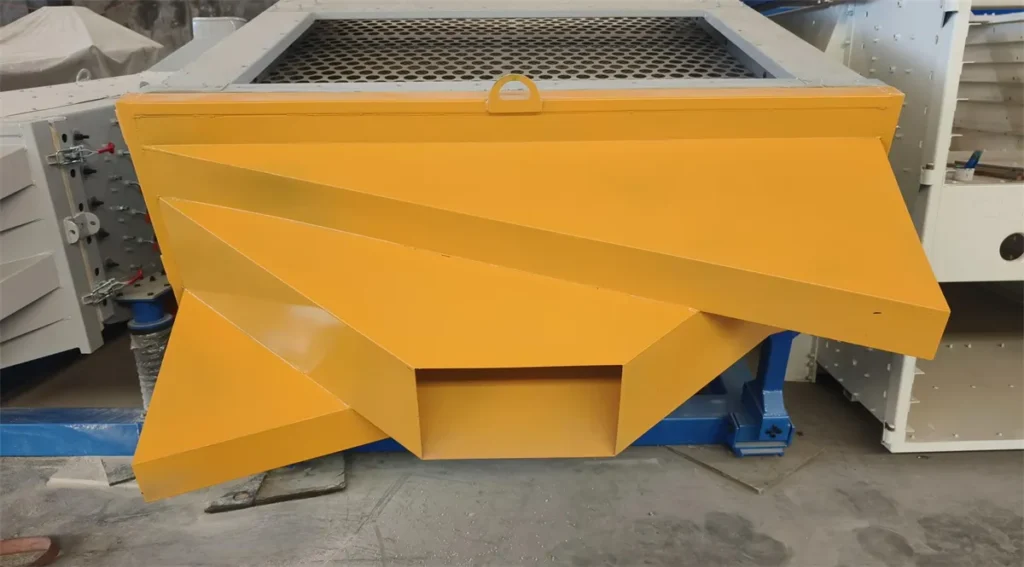

The Fully Balanced Square Gyratory Vibrating Screen Machine is a novel screening device independently developed by Sanyuantang Machinery to address the industry challenge of “large-particle-size material screening.” When processing graphite blocks, aluminum ingots, or performing sand and gravel mineral sorting, traditional equipment like the Large-Inclination Swing Probability Vibrating Screen and Linear Swing Vibrating Screen Machine often suffer from high energy consumption, excessive vibration impact, and material breakage issues.

In contrast, the Fully Balanced Square Gyratory Vibrating Screen Machine employs a fully dynamic balanced design, significantly reducing impact on support structures. Whether in chemical processing, food production, woodworking, or mineral screening—industries demanding precision and reliability—this machine adapts to diverse materials by adjusting the screen’s inclination angle through 360° regulation.

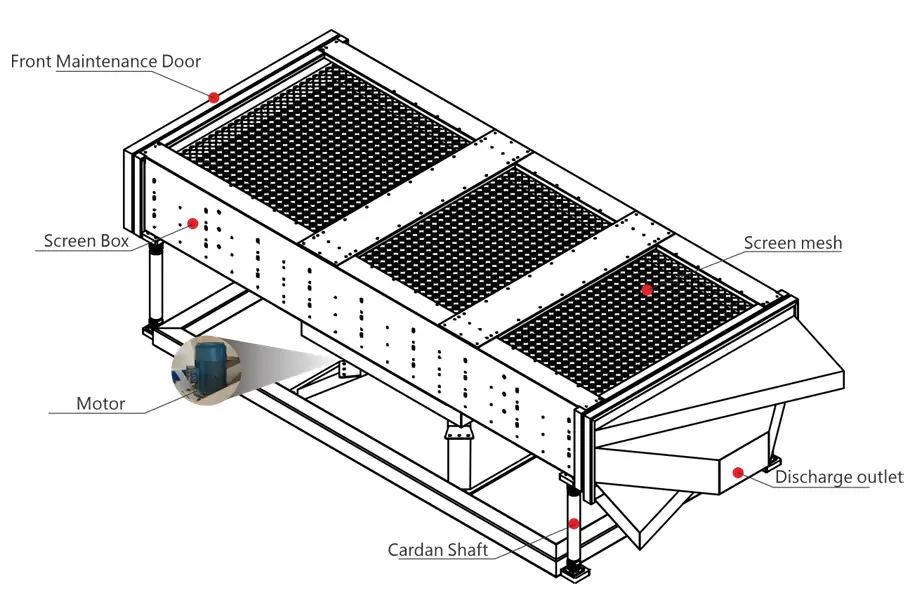

Parts of the Fully Balanced Square Gyratory Vibrating Screen Machine

The machine achieves its balance of high precision and stability through the seamless integration of its key components.

- Screen Box: The primary frame housing the screen plates, which vibrate to separate materials. Typically equipped with a front maintenance door for easy inspection, cleaning, and component replacement, minimizing downtime.

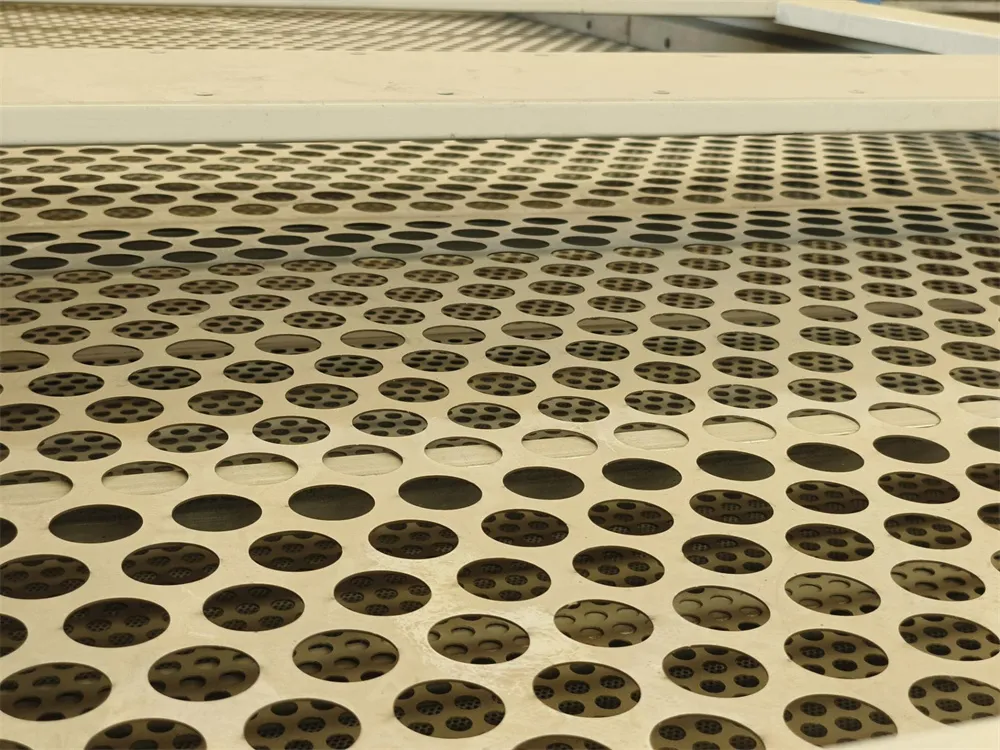

- Screen Mesh: Located within the screen box, it regulates material particle size categories by adjusting mesh count and aperture size.

- Cardan Shaft: Connects the screen box to the base while evenly distributing motor-generated power throughout the screen body. This ensures the fully balanced square gyratory vibrating screen machine maintains equilibrium during operation, minimizing vibration and mechanical wear.

- Motor: Typically employs a three-phase asynchronous motor to deliver stable and efficient power to the equipment.

- Discharge Chute: The inclined discharge structure enhances discharge efficiency and reduces material residue.

Discharge-outlet

Discharge-outlet Motor

Motor Front-Maintenance-Door

Front-Maintenance-Door Cardan-Shaft

Cardan-Shaft Screen-mesh

Screen-mesh

For specialized requirements, we can customize the geometric structure. Contact us for a bespoke solution.

Working Principle of the Fully Balanced Square Gyratory Vibrating Screen Machine

The fully balanced square gyratory vibrating screen machine employs a compound motion drive mechanism. This structure generates uniform rotary motion, evenly dispersing material across the entire screen mesh. High-amplitude oscillation continuously redirects material flow, preventing particle jamming in the screen mesh. The motor drives precision counterweights to generate centrifugal force and counterbalancing force, achieving self-stabilization of the machine body.

Unique Advantages of the Fully Balanced Square Gyratory Vibrating Screen Machine

- Flexible Screen Surface: The screen surface utilizes premium sheet metal or high-elasticity polyurethane material. These materials offer a smooth, wear-resistant surface that minimizes damage from material impact while accommodating varying hardness levels, such as graphite and aluminum raw materials.

- Omnidirectional Balance: Customers can freely adjust the screen surface angle to suit their needs. The machine maintains balanced operation even when positioned vertically or inverted, maximizing flexibility for customized capacity and quality requirements.

- Modular Design: Component replacement time is reduced to under 30 minutes, significantly minimizing production line downtime losses.

- Stable Operation: Actual data shows the Fully Balanced Square Gyratory Vibrating Screen Machine achieves over 10,000 hours of fault-free operation—50% longer than industry averages.

- Protects Floors and Support Structures: A unique motion balancing system neutralizes inertia and vibration, reducing stress on foundations and structural supports.

- Low Noise, Low Vibration: The equipment operates quietly and smoothly, minimizing noise pollution.

Industrial Applications of the Fully Balanced Square Gyratory Vibrating Screen Machine

Many industries face challenges like uneven discharge and material blockages under traditional screening conditions. The fully balanced square gyratory vibrating screen machine offers a new solution for these sectors.

Carbon Industry: Graphite blocks (10-50mm) in anode materials are difficult to separate by particle size, and traditional screening methods often damage the graphite structure. The Fully Balanced Square Gyratory Vibrating Screen Machine minimizes material damage and adjusts screening precision by altering the screen surface inclination, enabling rapid, uniform, high-precision classification without compromising graphite structure.

Wood Industry: Materials like wood chips, bamboo shavings, and palm fibers are lightweight and irregularly shaped. Traditional vibrating screens often cause floating, layering difficulties, and uneven discharge. High-frequency vibration can also lead to wood fibers tangling in the screen mesh or breaking. The low-frequency, flexible motion of the fully balanced square gyratory vibrating screen machine allows materials to move smoothly along the screen surface, achieving natural layering without damaging fiber structures.

Construction Industry: Building materials are typically irregularly shaped and highly abrasive, causing rapid screen wear, clogged apertures, and uneven particle size distribution during discharge. The fully balanced square gyratory vibrating screen machine features wear-resistant screens. Its adjustable inclination angle and interchangeable multi-layer screens enable precise grading of construction aggregates.

Fully Balanced Square Gyratory Vibrating Screen Machine VS Wood Chip Screener

| Product Type | Fully Balanced Square Gyratory Vibrating Screen Machine | Wood Chip Screener |

| Product Structure | Standard support structure | Suspended structure |

| Tilt angle | 0-90° | 8-10° |

| Working Principle | The composite motion drive mechanism generates uniform rotary motion during operation. The high-amplitude rotary motion continuously alters the direction of material flow, ensuring the material is evenly dispersed across the entire screening surface. | Driven by V-belts and synchronous belts, it generates reciprocating elliptical oscillation motion, which is transmitted to the screening bucket through components such as the screen box and screen mesh. |

| Application Industries | Carbon industry, building materials industry, wood industry | Wood processing, pulp and paper manufacturing, biomass energy |

Conclusion

The fully balanced square gyratory vibrating screen machine represents another innovation from Sanyuantang Machinery, efficiently addressing the challenges of screening large-particle materials across various industries. Compared to traditional equipment, it occupies less space, operates at lower noise levels, and causes minimal damage to materials. This significantly enhances screening efficiency and reduces costs in related industries.

With over 30 years of dedicated expertise, Sanyuantang Machinery is a comprehensive enterprise integrating design, R&D, production, and sales. The company holds multiple certifications and patents, with products distributed to over 100 countries and regions. If you are interested in vibrating screens, please contact us for professional advice and competitive quotations.