Vibrating screen spare parts mainly consist of four major parts: excitation system, load-bearing system, screening system, and support system. The specific configuration of different types of vibrating screens (linear, circular, high-frequency, etc.) varies slightly, but the basic framework is basically the same.

Vibrating Screen Spare Parts Components

Below is the functional introduction of key components:

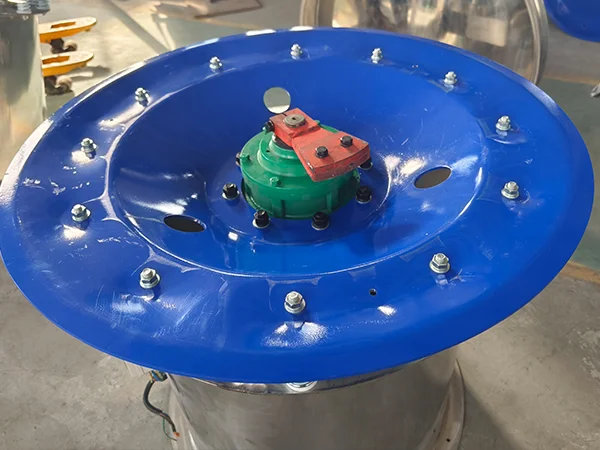

Excitation System

- Vibration motor (most common): generates centrifugal force by rotating eccentric blocks, driving the screen body to vibrate. It needs to match the equipment power to ensure uniform material dispersion.

- Exciter: includes eccentric blocks, bearings, transmission shafts, etc., and can adjust the excitation force by adjusting the eccentric block angle.

- Ultrasonic system (ultrasonic vibrating screen): composed of ultrasonic generator and transducer, superimposes high-frequency vibration (20-40KHz) to solve the problem of fine powder blocking the screen.

Screening main frame: Load-bearing system

- Screen box: welded or bolted from steel plates, requiring high strength and rigidity to withstand vibration impact.

- Screen frame: the structure that supports the screen mesh, made of pine wood (traditional) or metal material, and needs to keep the screen mesh flat and tight.

- Crossbeam: connects the side plates of the screen box, enhances overall stability, and is mostly made of seamless steel pipe or section steel.

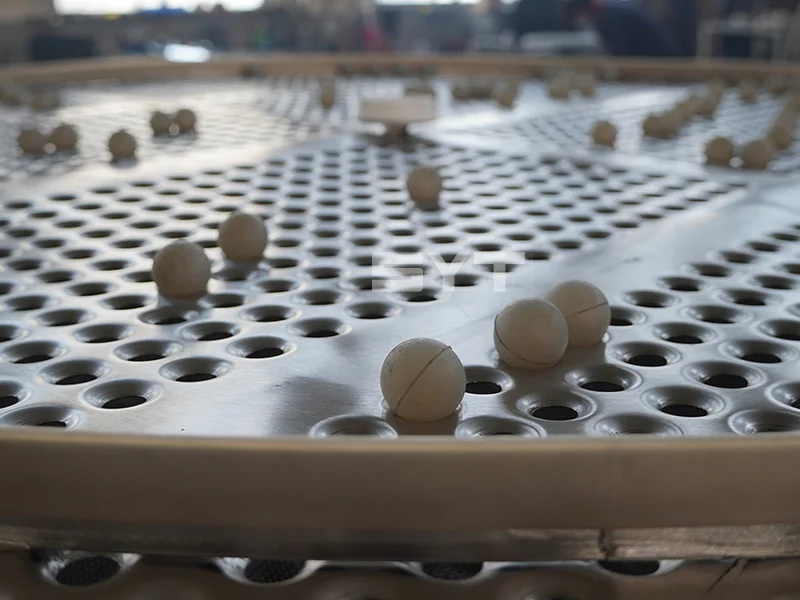

Screening System: Vibrating Screen Spare Parts

The screen mesh is the key component of vibrating screen spare parts that directly contacts the material. The most common materials are:

- Metal: stainless steel, carbon steel (wear-resistant)

- Non-metal: polyurethane, nylon (acid and alkali resistant)

- Special: ultrasonic screen mesh (fine screening)

- Screen plate: perforated plate, woven mesh, slotted screen, etc., selected according to material characteristics.

Vibration reduction and stability: Support system

Vibration damping spring: commonly used rubber springs or coil springs to reduce vibration transmission to the ground and reduce noise.

Support/base: supports the entire equipment, and must ensure level installation to avoid eccentric load.

Isolation device: high-end models adopt air springs or composite shock absorbers to further reduce dynamic load.

Auxiliary accessories

Cleaning device: bouncing balls, ultrasonic, brushes, etc., to prevent material blocking the screen.

Sealing structure: dust cover, rubber sealing strips, suitable for occasions with large dust or high hygiene requirements.

Lubrication system: automatic grease injection device to extend bearing life.

Key differences:

Linear vibrating screen: two motors rotate synchronously in opposite directions, and the trajectory is a straight line.

Circular vibrating screen: driven by a single motor, the trajectory is circular or elliptical.

Ultrasonic vibrating screen: vibration frequency is above 3000 times/min, suitable for fine materials.

Maintenance focus:

- Check the screen mesh tension daily to prevent material leakage.

- Replace motor grease after a total running time of 2000 hours.

- Regularly check whether the damping springs are cracked and whether the support bolts are loose.

- Vibrating screens in different industries will optimize component materials and structures according to material characteristics (such as corrosiveness, viscosity, particle size).

For example, the food and pharmaceutical industries mostly use stainless steel materials, while the mining industry requires heavy-duty design.

If you need vibrating screen spare parts replacement, customization, or bulk procurement, welcome to contact us, Sanyuangtang Machinery. We have 30 years of vibrating screening manufacturing experience, and we also have a professional team to provide you with solutions.

Email: info@sanyuantang.com

Phone: +86-18639095165