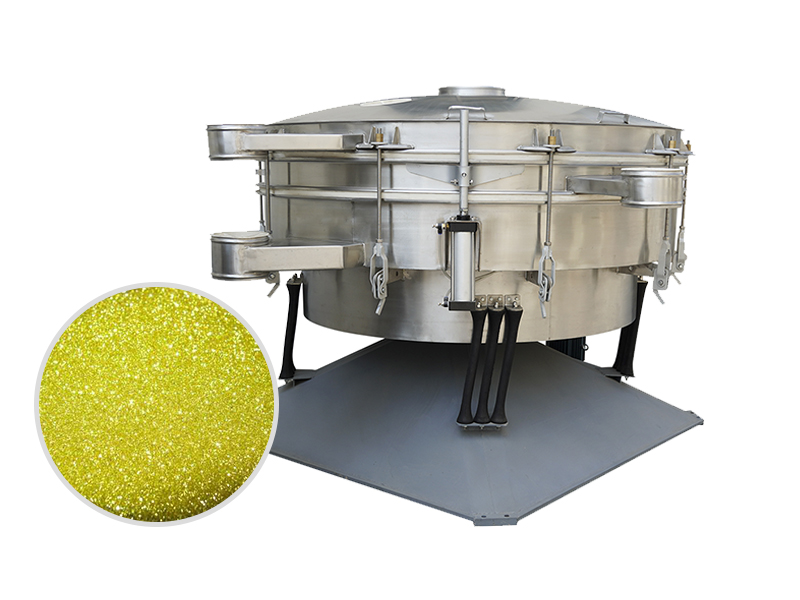

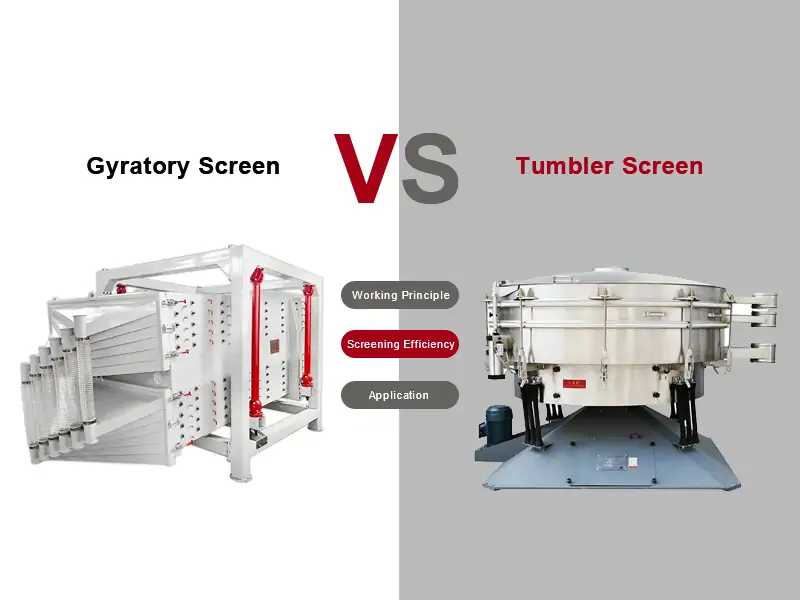

The tumbler screening machine, also known as a tumbler screener, is designed for high-capacity and efficient screening of fine and ultra-fine powders. It imparts rotary and gyratory motion to the screened material, facilitating efficient particle separation. This type of machine is commonly used in various industries, including food processing, pharmaceuticals, chemicals, and minerals.

- Model: YBS-2600/2200/2000/1600/1200/1000

- Material: Carbon Steel/Stainless Steel 304/316L

- Mesh Size: 2-500 mesh

- Layers: 1-10 layers

- Motor Power: 5.5kW/7.5 kW

- Capacity: 500-4500 kg/h

- Customized: Acceptable

Price: $5,020.00 – $9,535.00 / Set

Application

- Abrasive material and ceramic industry:

Building sand, mica, alumina, abrasive, refractory material, slurry, etc. - Chemical industry

Resin pigment, medicine, grease, paint, palette, etc. - Food industry

Sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc. - Metallurgy and mining industry

Quartz sand, ore, titanium oxide, zinc oxide, etc. - Mechanical industry

Casting sand, powder metallurgy, electromagnetic material and metal powder, etc.

Metal Powder

Metal Powder Paint

Paint Medicinal powder

Medicinal powder Emery

Emery Glass Powder

Glass Powder Light calcium powder

Light calcium powder Plastic particles

Plastic particles Rubber Powder

Rubber Powder Cork powder

Cork powder

Working Principle

The tumbler screening machine is a low-frequency rotary vibrating screen that imitates artificial shaking. Its principle is that the instantaneous motion is the synthesis of the displacement along the radial direction and the circular motion with the displacement as the axis (spiral motion), which can adjust the eccentricity excitation. The vibration motor produces non-linear three-dimensional motion, and the material also produces the same movement that is similar to manual operation, thereby achieving the purpose of screening. A more ideal screening effect can be obtained when combined with screening accessories.

Specifications

| Model | Availability of screening area(m*m) | Screen slope (angel) | Grain size(mm) | Frequency (r/min) | Double amplitude(mm) | Power(kw) | Power(kW) |

|---|---|---|---|---|---|---|---|

| HXSY -1000 | 0.785 | 0-10 | ≤100 | 750 960 1500 | 5-8 | 1.5 | 8-15 |

| HXSY -1200 | 1.13 | 2.2 | 15-30 | ||||

| HXSY -1600 | 1.83 | 2.2 | 25-50 | ||||

| HXSY -2000 | 2.63 | 4.0 | 30-60 | ||||

| HXSY -2600 | 5.31 | 5.5 | 45-60 |

Features

1-5 layers of screen mesh, each layer of screen mesh achieves precise classification of coarse and fine particles. Material screening can reach 6 particle sizes.

Get double or even higher production capacity on the same screen.

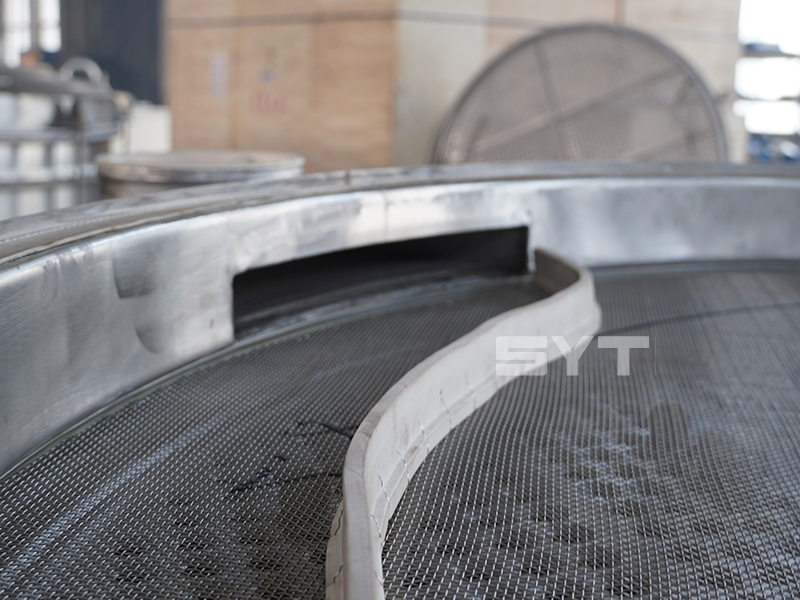

Not easy to block the Screen

A variety of cleaning systems to solve the problem of network blocking. Used for materials with high viscosity or static electricity.

Handle materials gently to reduce damage

The shaking screen imitates the manual screening movement, making the screening softer and effectively reducing the breakage of fragile materials.

Easy to operate

Network replacement is more convenient, simple to operate, and runs smoothly.

Easy to maintain

Quick and easy disassembly and installation in as little as 15 minutes. Only the bearings need to be lubricated regularly to ensure continuous operation of the equipment at full load.