Application Of Gyratory Screen In Different Industries

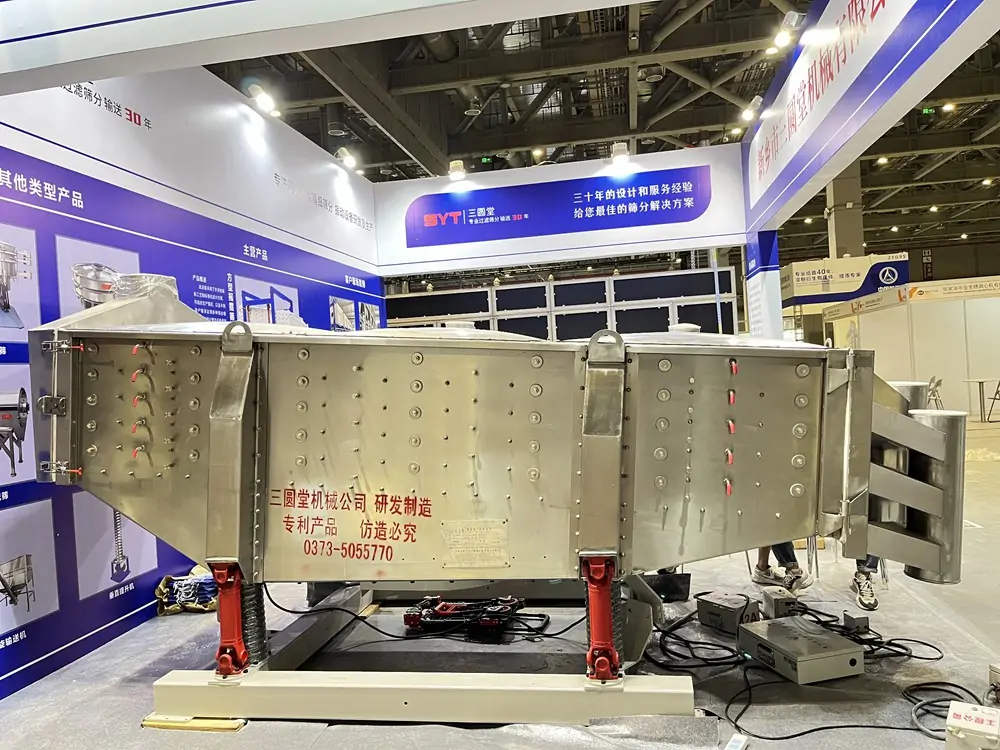

The gyratory screen is a highly efficient screening equipment, mainly divided into round gyratory screen and square gyratory screen, which is used in many industries. The gyratory screen simulates the working action of manual screening, and with the vibration in the horizontal and vertical directions, it can effectively improve the screening efficiency and accuracy, while reducing the problems of material blockage and wear. This article will explain the specific application and advantages of the gyratory screen in different industries.

Fine Screening Industry

In the chemical production line, the gyratory screen has excellent screening capabilities. Taking pigment production as an example, the equipment can accurately separate pigment particles of different finenesses to make each batch of products have consistent color. Paint manufacturers rely on their excellent screening capabilities to remove lumps and impurities in raw materials, making the paint more perfect and smooth in use. In the resin processing link, the product particle size distribution can be effectively controlled to meet the special needs of different customers.

The food processing industry has strict hygiene requirements for screening equipment. The gyratory screen is made of food-grade stainless steel. In the flour refining process, it can effectively remove impurities such as wheat bran; in the powdered sugar production line, it can make the particles uniform; in the starch processing link, it can accurately control the fineness of the product. These applications not only improve food quality, but also ensure consumer food safety.

Grading Screening Industry

In mining production, screening equipment has extremely high processing capacity requirements. The gyratory screen has a large processing capacity and a low failure rate. It can quickly separate ores of different particle sizes in the primary selection of ore; in the coal washing process, it can effectively distinguish clean coal, medium coal and gangue. Its good characteristics are widely used in mining production.

In the production of sand and gravel aggregates in the building materials industry, the equipment can accurately grade according to the standards for building sand; in cement grinding stations, it is used to control the fineness modulus of cement products. It is worth mentioning that its dust-proof design effectively reduces dust pollution in cement production.

Impurity Removal And Screening Industry

The pharmaceutical industry has almost stringent requirements for the purity of raw materials. The gyratory screen can completely remove impurities such as fibers and foreign matter in the drug powder screening process; in the drug particle classification link, it can accurately control the particle size range of the drug particles.

Application in the agricultural field. In seed processing plants, gyratory screens can efficiently separate seeds of different varieties and specifications; in feed production enterprises, they can remove foreign matter such as sand, gravel, and metal in raw materials.

Particle Shaping Industry

The plastic processing industry has strict requirements on the appearance of particles. The gyratory screen can effectively screen out irregular particles and powder in the production of PE, PP and other plastic particles; it can remove impurities and unmelted flakes in the processing of recycled plastics.

Rubber products industry. In the screening of natural rubber particles, the equipment can remove impurities such as bark; in the synthetic rubber production line, it can control the particle size distribution of the product.

Conclusion

The reason why the gyratory screen can be widely used in many industries lies in the rationality of its design: the low speed operation not only ensures the screening efficiency, but also extends the service life of the equipment; the modular design makes maintenance more convenient; a variety of screen configuration schemes can meet the screening needs of different materials. These characteristics make it an indispensable key equipment in modern industrial production.