There are two major pain points in the sand making industry: high moisture content and low screening efficiency. In the past, traditional screening equipment could not meet the needs of dehydration and screening at the same time, resulting in the industry: the finished sand moisture content is too high, the loss of fine sand is serious, the equipment wears quickly, and the production cost remains high. However, the emergence of dewatering vibrating screen has solved these two major problems. This article will introduce the working principle, steps and applications of dewatering vibrating screen in sand making industry in different industries.

Working principle and dehydration steps

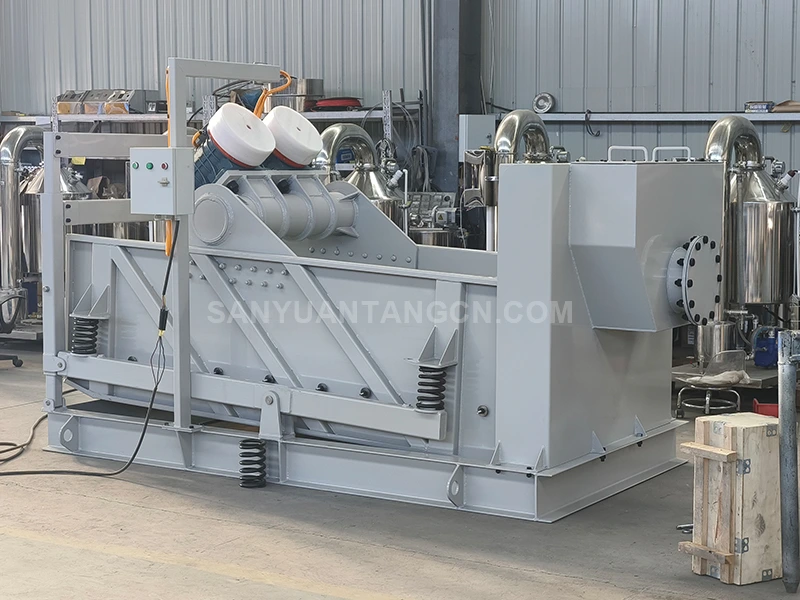

The dewatering vibrating screen is a screening and dewatering equipment that combines high-frequency vibration with multi-layer screens. It is specially designed for solid-liquid separation of high-humidity materials such as ore sand, tailings, and machine-made sand.

In the sand making industry, the dewatering vibrating screen effectively solves the problems of high moisture content and fine sand loss in the wet sand making process through high-frequency vibration, gravity drainage, and multi-layer screens.

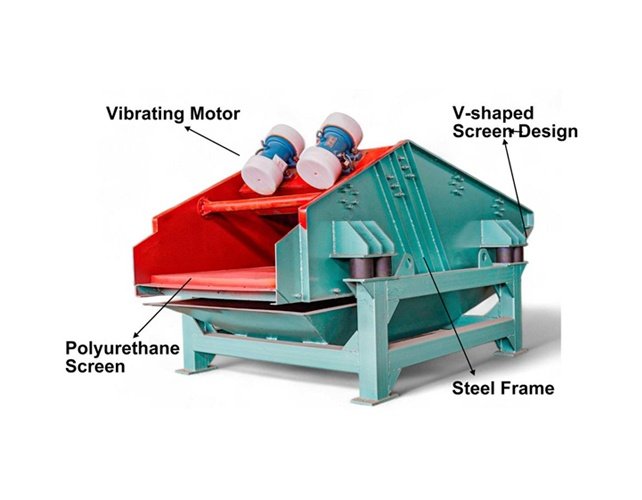

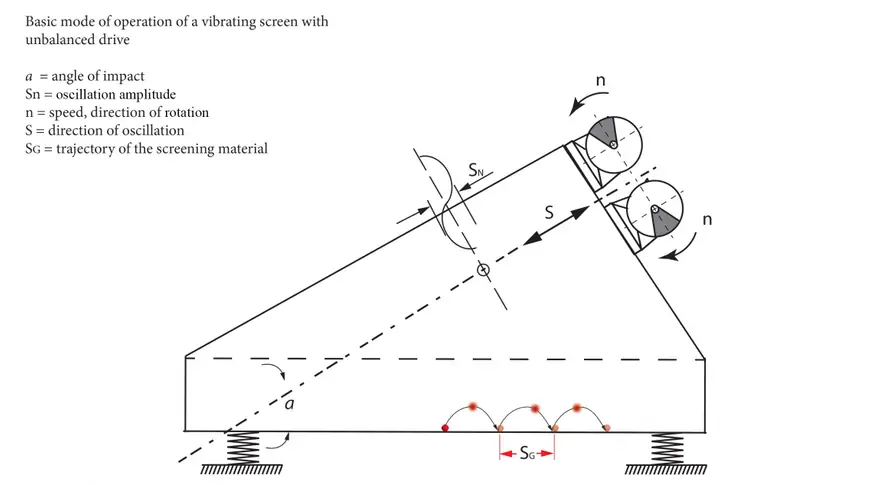

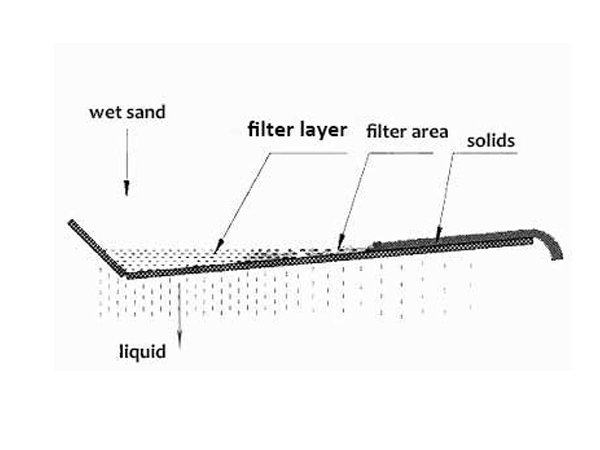

Working principle: The vibration motor generates high-frequency linear vibrations of 1500-3000 times/minute, causing the material to jump forward on the multi-layer screen surface inclined at 15°-25°. The upper screen (2-5mm) completes the coarse particle classification, the middle screen (0.5-1mm) recovers fine sand, and the bottom screen (below 0.074mm) realizes mud and water separation, allowing the water to be quickly discharged through the screen holes.

In the sand and gravel aggregate production line, the dewatering vibrating screen completes efficient dewatering and screening in four steps:

Basic dewatering: wet sand after sand washing enters the screen surface, and high-frequency vibration makes the material evenly thinned;

Grading screening: coarse particles are transported forward along the screen surface, and fine sand falls through the screen;

Deep dewatering: the fine sand layer is constantly churning under the action of vibration, and the water is forced to be discharged from the screen;

Dry material collection: the dehydrated finished sand (water content ≤8%) is discharged from the discharge port, and the mud is centrally processed through the bottom water guide trough.

This process can reduce the moisture content of the finished sand from 15%-20% to below 8%, recover more than 90% of 0.075mm fine sand, and reduce 30% of drying energy consumption. It is a key equipment for modern sand production line manufacturers to improve quality and reduce costs.

Application Performance, Advantages and Improvement Suggestions of Dewatering Vibrating Screen in Various Industries

| Industry | Main Issues | Dewatering Screen Solutions | Key Advantages | Improvement Suggestions |

| Aggregate Production (Granite/Basalt) | 1. High moisture content 2. Impacts concrete strength 3. High transportation cost | 1. Post-washing dewatering 2. Effective fines recovery | 1. Reduces drying costs 2. Improves product yield 3. Meets construction standards | 1. Use variable frequency models 2. Regular screen inspection |

| Tailings Management (Gold/Iron Ore) | 1. High water content 2. Large tailings ponds required 3. Environmental risks | 1. Combined dewatering process 2. Significant moisture reduction | 1. Lowers tailings storage costs 2. Enables dry stacking 3. Minimizes wastewater | 1. Select corrosion-resistant materials 2. Add self-cleaning mechanism |

| Sand Washing Plants (River Sand/Crushed Stone) | 1. Significant fines loss 2. Incomplete cleaning | 1. Double-layer dewatering 2. Fines recovery system | 1. Greatly improves fines recovery 2. Reduces clay content | 1. Optimize screen angle 2. Regular drainage maintenance |

| Coal Preparation | 1. Excess moisture in clean coal 2. Slurry handling difficulties | 1. Integrated dewatering system 2. Effective slurry dewatering | 1. Enhances coal quality 2. Reduces transport costs | 1. Use explosion-proof models 2. Install wear-resistant parts |

| Quartz Sand Processing | 1. High moisture after acid washing 2. Fine particle loss | 1. Acid-resistant screens 2. Multi-stage dewatering | 1. Significantly reduces moisture 2. Improves fines recovery | 1. Implement special cleaning 2. Monitor process parameters |

Through different performances in different screening industries, we can clearly feel the advantages of dewatering vibrating screen in dewatering screening. Dewatering vibrating screen helps various industries achieve: reducing energy consumption, improving efficiency and meeting environmental protection standards through different application solutions. It will be one of your important equipment in dewatering screening, come and buy it now!

Conclusion

Through the above explanation, the dewatering vibrating screen has proved its excellent dewatering and screening performance and the advantages of increasing efficiency and reducing costs in practice in many industries. The dewatering vibrating screen will continue to promote the mining sand making industry to develop in the direction of high efficiency, energy saving, green and environmental protection, and create greater economic benefits and market competitiveness for enterprises.

As a provider of overall fine screening solutions, Xinxiang Sanyuantang Machinery Co., Ltd. relies on 30 years of technical accumulation and innovation strength to provide customers with efficient, stable and energy-saving dewatering screen equipment, helping enterprises to achieve a dual improvement in production efficiency and economic benefits. Contact us now to escort your screening production