In wood processing, panel manufacturing, and the biomass energy industry, wood chips and sawdust are the most commonly used products. However, in actual production, raw wood chips are often mixed with impurities such as branches, stones, and gravel. Without effective screening, these contaminants can compromise the subsequent usability of the wood chips. Thus, the wood chip screener was developed. Among these, Sanyuantang Machinery’s independently developed Four-Vibration Source Square Oscillating Screen, also known as the wood chip screener, has gradually become one of the primary pieces of equipment in the wood processing industry. Its unique four-vibration-source design and highly efficient screening capability set it apart.

Structure and Features of the Four-Vibration Source Square Oscillating Screen

This equipment utilizes four vibration sources, ensuring uniform vibration and flexible frequency adjustment for different materials, thereby stabilizing screening results. The screen section typically employs wear-resistant perforated metal plates, which are not only durable but also configurable with various aperture sizes to achieve multi-stage screening according to customer requirements. The equipment can be configured with up to five screening layers, enabling simultaneous classification of large wood chips, medium-sized wood shavings, and fine sawdust.

At the feed end, the equipment features an umbrella-shaped distributor and a material control gate. The distributor evenly disperses wood chips across the screen surface, preventing material buildup that could reduce screening efficiency. The control gate adjusts feed rate according to operational requirements.

The Role of Wood Chip Screeners in Production

Wood chips are one of the most common byproducts in wood processing. Sawdust is loose and lightweight but often contains mixed debris such as branch fragments, stones, or metal impurities. Without effective screening, these contaminants severely impact wood chip reuse. For instance: in biomass fuel briquette production, stone impurities cause mold damage; in particleboard manufacturing, oversized branches compromise board density and surface flatness.

The wood chip screener effectively resolves these issues. Through multi-layer screening, wood chips of different sizes are clearly separated: large particles remain on the upper screen, medium-sized chips pass through the middle layer, and finer sawdust is collected on the bottom layer. This grading process significantly improves wood chip classification and subsequent utilization rates.

Advantages of the Four-Vibration Source Square Oscillating Screen

Compared to traditional equipment, the Four-Vibration Source Square Oscillating Screen offers significant advantages in the following areas:

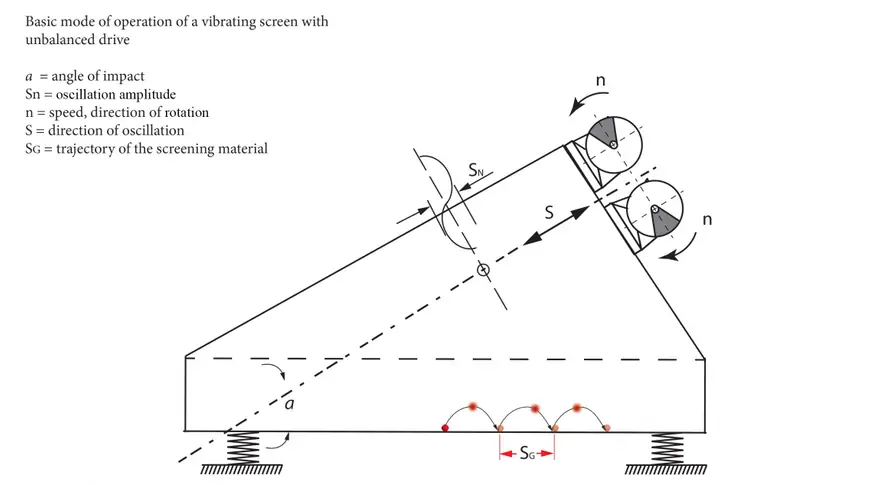

- High Screening Efficiency: Multi-point vibration sources ensure uniform force distribution across the screen surface, enabling rapid chip passage and reducing clogging.

- Intelligent Vibration Frequency Adjustment: Adaptively modifies vibration parameters based on wood species, moisture content, and material properties, effectively preventing wet wood adhesion and lightweight material dispersion.

- Fully Enclosed Design: Prevents dust leakage, meets environmental standards, and improves workplace conditions.

- Multi-Stage Screening Capability: Configured with three to five screen layers, it achieves precise grading of materials across different sizes in a single pass.

- Low Maintenance Costs: Metal perforated screens offer wear resistance and impact durability for extended service life; the four-vibration-source design reduces load on individual motors, lowering equipment failure rates.

Application Fields of Wood Chip Screener

The wood chip screener is not only suitable for separating ordinary wood chips and sawdust but is also widely used in the following industries:

- Biomass Energy Industry: Screened wood chips are used to produce wood pellet fuel, offering higher combustion efficiency and more stable quality.

- Plywood Manufacturing: Production of particleboard, MDF, and plywood demands strict wood chip particle size specifications. Screening ensures uniform raw materials, enhancing board quality.

- Agriculture and Horticulture: Screened fine wood chips serve as mulch or soil conditioners, reducing moisture evaporation and improving soil structure.

- Animal Bedding: Clean, uniform wood chips are commonly used as bedding in livestock farming. Screening removes harmful impurities, ensuring a safe rearing environment.

- Activated Carbon and Paper Manufacturing: Some enterprises require wood chips as raw material. Screening yields particle sizes that better meet production specifications.

Sawdust

Sawdust wood chips

wood chips Wood pellets

Wood pellets wood chip

wood chip

Conclusion

Sanyuantang Machinery Four-vibration source square Oscillating Screen – Wood chip screener with its excellent performance, for sawdust, wood chips, wood chips and other mixed wood materials such as fast and accurate screening provides an ideal solution, not only allows you to improve the production efficiency, reduce production costs, but also through the enhancement of product quality to enhance the competitiveness of enterprises in the market.