Quartz sand is a non-metallic mineral, widely used in glass, abrasives, casting, construction, fireproof materials, etc. The quartz sand vibrating screen is mainly used to coarse or fine screen the quartz sand for multi-layer classification.

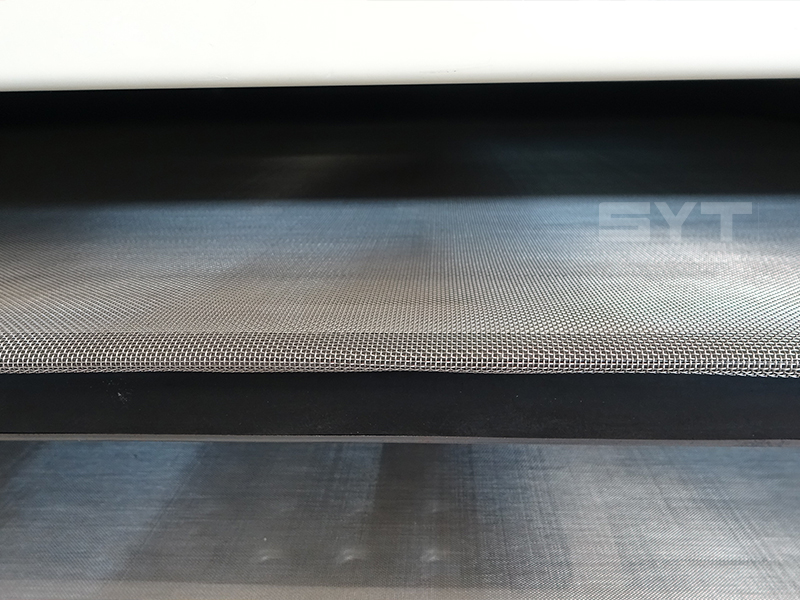

The common specifications of the vibrating sand screening machine screen are: 0.5-1mm, 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20 mesh, 20-40 mesh, 40-80 mesh, 100-250 mesh.

- Model: FYBS-1536, FYB-S2040

- Number of layers: 1-10 layers

- Screening mesh: 4-140 mesh

- Output: 10-30t/h

Price: $14800.0 – 23400.0 / Set

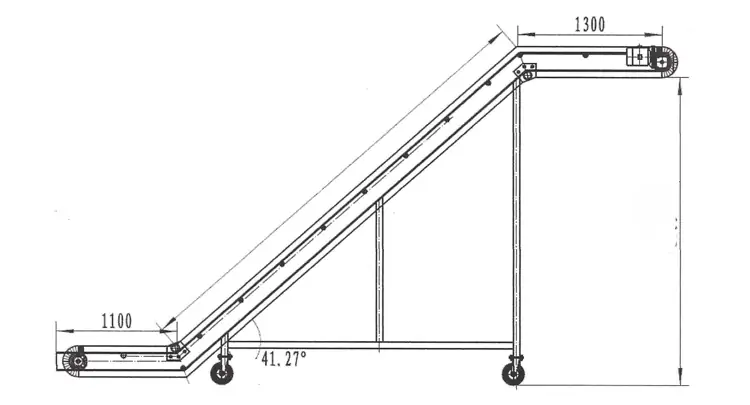

Quartz Sand Grading Process

- First, the stone is initially crushed by the coarse crusher, and then the coarse material produced is conveyed to the fine crusher by the belt conveyor for further crushing. The finely crushed stone enters the vibrating screen to screen out two kinds of stones. The stones that meet the feed particle size of the sand making machine enter the sand making machine, and the other part of the return material enters the fine crushing. Part of the gravel entering the sand making machine is made into sand, which is then cleaned by the sand washing machine to form finished sand, and the other part is crushed again by the sand machine.

- The production line has a high degree of automation, low operating cost, high crushing rate, energy saving, large output, less pollution, and easy maintenance. The machine-made sand produced meets national standards, the product particle size is uniform and the particle shape is good.

Quartz Sand Production Line Equipment

Quartz Sand Screening Analysis

- Quartz sand multi-layer classification, different particle sizes have different uses, water content is less than 7% and dry material without sticky material screening. Finished coarse materials generally have 4 mesh, 8 mesh, 16 mesh, 30 mesh, 50 mesh, 80 mesh, 100 mesh, 140 mesh. Screening accuracy> 90%, requiring the same specification of particle size uniform and neat, without large particles and fine powder.

- At present, due to the efficiency problem of the sand-making machine, the finished product of the sand-making machine with an output of 100 tons per hour only accounts for 20-30%, which requires a large-capacity square gyratory sifter to complete. The single gyratory sifter is 3-5 times that of an ordinary vibrating screen.

- Quartz sand vibrating screen is usually used for screening and classifying non-sticky quartz sand, quartz powder, quartz stone, machine-made sand, artificial sand, and other materials with a particle size of 0.074~5mm, moisture content of less than 7%, and no cohesiveness. This equipment can change the screen surface spacing and inclination angle according to the material particle size and screen penetration probability to achieve flexible adjustment. At the same time, it can screen multiple layers of materials and separate a variety of quartz sand of different specifications without mixing or bunching.

Working Principle

Judging from the direction of rotation, the sand vibrating screen is also called a swing vibrating screen. The vibration force generated by the driving device is an inertial force along the fixed axis, and its direction changes according to certain rules. The essence of the square vibrating screen machine is the reciprocating inertia force formed by the rotation of the eccentric wheel around the fixed axis. According to the vibrating screen machine working principle and structural characteristics, the screen surface is arranged to tilt at a certain angle (the tilt angle is generally 5-8 degrees). After the vibrating screen machine is opened, the screen box makes a reciprocating motion under the action of vibrating screen exciter force.

The sand vibrating screen box drives the screen surface to shake periodically, causing the materials on the screen surface to make directional jumping motions with the screen box. During this period, materials smaller than the screen hole fall to the lower layer, and materials larger than the screen hole make a jumping motion and are discharged from the coarse-grained outlet. After the rotary screen is started, under the action of the vibrator, the shaking body of the screen machine makes a reciprocating motion under the action of inertial force. The screen box drives the screen surface to shake periodically, causing the materials on the screen surface to make directional jumping motions together with the screen box.

Quartz Sand Vibrating Screen Videos

Structures

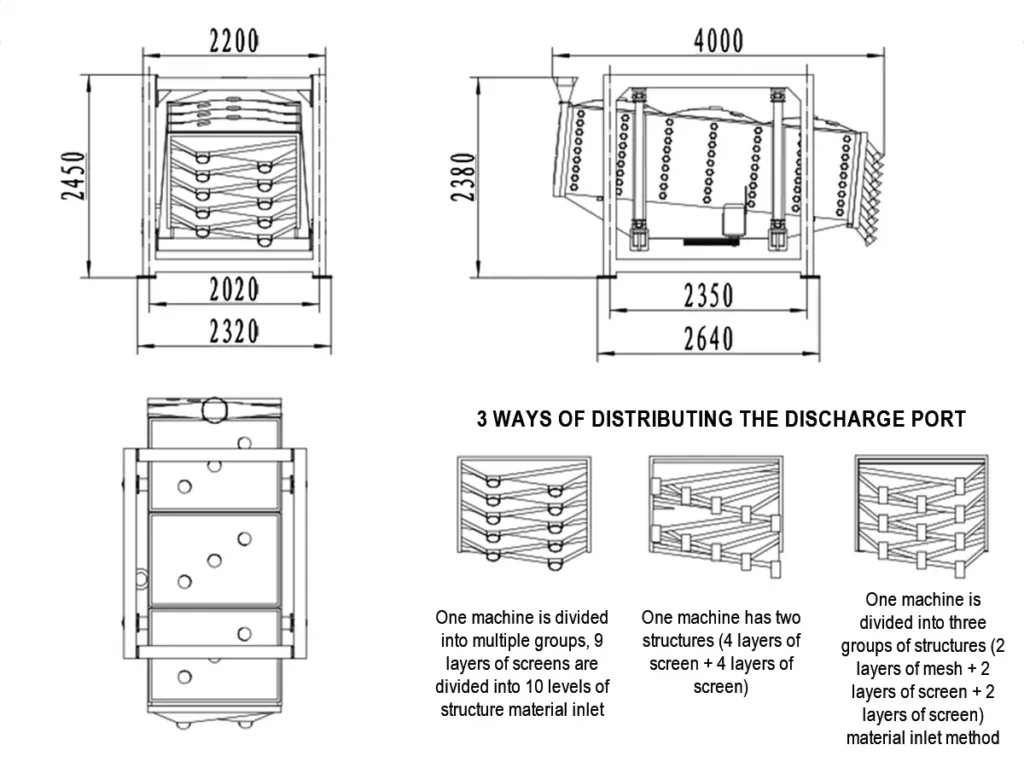

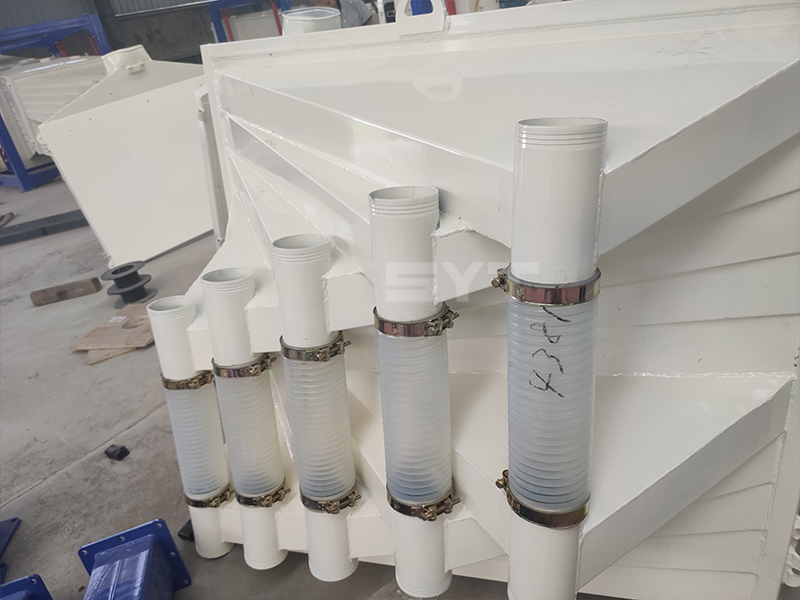

Quartz sand vibrating screens mostly use gyratory screens, with 1-10 screen layers, which can sort quartz sand materials into 2-9 different specifications at the same time. In addition, Sanyuantang can customize the screen box height, the passing space between the screen plates, the motor’s drive size, the grid’s structural style, the discharge port’s orientation, etc. according to the material particle size and grading requirements on site.

sand Vibrating Screen details

Specifications

| Model | Screen size | Screening area | Screen inclination | Layers | Power | Number of turns | Case travel |

|---|---|---|---|---|---|---|---|

| FYBS1536 | 1.5*3.5 m | 4.5-9 m2 | 5-8 | 1-10 | 5.5 | 180-260 | 25-60 mm |

| FYBS2040 | 2.0*4.0 m | 8-9 m2 | 5-8 | 1-10 | 7.5 | 180-260 | 25-60 mm |

Features

- The vibrating sand screen adopts a multi-layer structure, which is especially suitable for materials that require a multilayer vibrating screen. This structure can effectively improve screening efficiency. It also has an automatic screen cleaning device to avoid material clogging.

- The output per unit area can reach 5 times; the separation is accurate to 6 levels, and the screening efficiency is as high as 90%-99%.

- Transmitting vibrating screen exciter to the screen surface, the square vibrating screen machine can quickly stratify the materials on the screen surface, thereby improving screening accuracy.

- The frequency and amplitude of the vibrating screen machine can be adjusted as needed to adapt to the screening requirements of different materials.

- The structure of the sieve machine is relatively simple and easy to maintain. At the same time, the screen mesh adopts a pull-tension type and can be easily replaced.

- The square vibrating screen machine is suitable for screening various powdery and granular materials, can also be customized as needed to meet the screening requirements of different industries.

Customer Site

Professional Sand vibrating screen Machine Manufacturer

We are a professional vibrating screen manufacturer in China. We have strong technical strength, committed to developing and producing a sand vibrating screen machine. Our company has an experienced technical team that continuously explores innovates and conducts in-depth research on the core technology of sand vibrating screen machines to ensure the advancement and reliability of the products. We focus on combining technology research and development with market demand and continuously launch sand vibrating screen products that meet market demand to meet the diverse needs of customers.

Our sand vibrating screen machines have been widely recognized and praised in the market. Our products have been successfully applied in sand screening operations in many fields, such as mining, construction, highway roads, etc. Customers have spoken highly of our products, believing that our products have stable performance, reliable quality, and considerate after-sales service. We always adhere to the customer-centered concept and provide customers with high-quality products and services. If you are interested in our machine or have any questions, please contact us, and we will serve you wholeheartedly.