What is a vibrating screen?

Sanyuantang is a Chinese vibrating screen supplier. We have been focusing on overall screening and conveying solutions for 30 years. The vibrating screens we produce have obtained US patents and 40 domestic patents in terms of function and technology, and are in a leading position in the industry. Sanyuantang vibrating sieving machines are mainly divided into the following types according to different structures and working principles. Please choose the appropriate product type based on actual needs, or contact us directly to provide you with a one-stop screening and conveying solution.

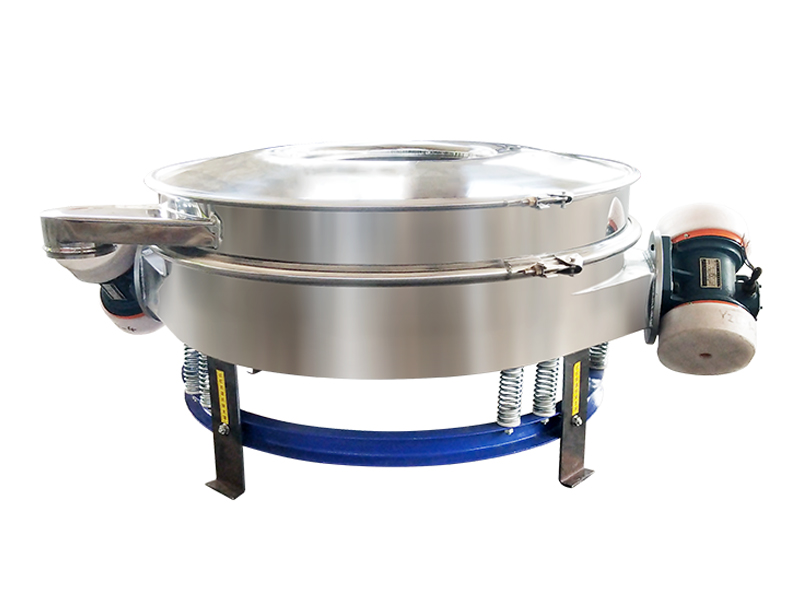

Circular rotary vibrating screen

The rotary vibrating screen is suitable for fine screening of materials with fine particle size and strong viscosity. For materials that require efficient separation, the rotary vibrating screen has a higher screening efficiency, which can reach more than 95%. It also has the advantages of low noise, small footprint, and easy cleaning, and is suitable for screening small batches of materials.

Application: Various powder industries. Any particles, powders, and slurry can be screened within a certain range.

Tumbler vibrating screen

The tumbler vibrating screen is modeled on the low-frequency and high-efficiency principle of imitating manual screening, suitable for continuous screening and classification of granules, powders, liquids and viscous materials, with a screening accuracy of 90-95%. it can screen 80-500 meshes and is accurate to 6-level separation. The screening efficiency is as high as 90%-99%. It uses silicone rubber balls, ultrasonic and other high-efficiency screen cleaning device systems, screen holes will not be clogged.

Application: flour, salt, graphite, spices, feed, plastics, rubber, chemical fertilizers, sugar and salt and other precision, brittle and irregular materials.

Inline Sifter Machine

The inlet and outlet of the inline sifter machine are in the same vertical direction, that is, the straight-row screen is used, and the screened materials are directly discharged through the screen at the discharge point. The screening speed is fast and the material is discharged quickly. It is suitable for screening large output and coarse materials, with an output of up to 30 tons per hour. Suitable for drying, dust removal, screening, etc. of granules, powders, and slurries.

Application: flour, fertilizer granules, pebbles, food additives, lime powder, condiments, sodium sulfate, metal powder, chemical raw materials, starch, silicon carbide, zinc oxide powder, puffed soybeans, feed additives, calcium powder, soda ash.

Linear vibrating screen

The linear vibrating screen is mainly used to remove impurities, for high-fluidity powder and particle processing, and to quickly remove large particles or fine powder with low content. It has a simple structure and is suitable for screening a large amount of materials. It has the characteristics of high efficiency and high output.

Application: food spices, Chinese herbal medicine, tea, silica powder, chemical fertilizers, plastic particles, resin, machine-made sand, quartz sand, etc.

Gyratory vibrating screen

The gyratory vibrating screen adopts the principle of plane rotation, the rotation frequency is 180-260 rpm, and the screen surface inclination angle is 0~5°. It can have a good screening effect on materials below 300 mesh, and the screening efficiency can reach more than 98%. It has a stable structure and smooth operation and can meet the screening needs of high intensity and large output.

Application: quartz sand, machine-made sand, fracturing sand, garnet, brown corundum, resin, compound fertilizer, reduced iron powder, zirconia, ceramsite, barite, wood chips, etc.

Function of vibrating screen

The main functions of vibrating screening machines include:

- Screening: Screen the raw materials according to different particle sizes to separate products with the required particle size.

- Removal of impurities: Impurities and foreign matter in raw materials are removed through the screening process to improve product quality.

- Grading: According to the requirements of different particle sizes, the raw materials are graded to meet the needs of different industries.

applications of vibrating screens

Vibratory screens are widely used in various industries, including but not limited to:

- Mining: Used for screening and grading raw materials such as coal and ore.

- Chemical industry: used for screening and filtering chemical raw materials, such as granules, powders, etc.

- Food Beverage: used for screening and classifying food powders, grains, etc. in the food processing industry.

- Pharmaceutical: Used for screening and filtering of medicinal materials and powders in the pharmaceutical industry.

- Vibrating screens provide important support and guarantee for the production of various industries through their efficient and precise screening capabilities.

Trustworthy China Vibrating Screen Supplier and Manufacturer

As a professional China vibrating screen supplier and manufacturer, Sanyuantang is committed to providing high-quality, high-performance vibrating screens and related equipment. The company has advanced production technology and rich experience, provides customers with a full range of vibrating screen solutions, and has established a good reputation and credibility in the industry.