Project Background

In the production process of color masterbatch, plastic pellets and PVC pellets are typically at a high temperature after extrusion or pelletization. If cooling is insufficient, problems such as pellet deformation, adhesion, and agglomeration are likely to occur, which can affect the stability of subsequent packaging, weighing, and conveying.

In this case, the customer hopes to achieve fast plastic pellet cooling and stable plastic pellet conveying in a limited space, while ensuring continuous output and pellet integrity, with high requirements for equipment stability and process matching.

Customer Material and Working Conditions

Material Type: Color masterbatch / Plastic pellets / PVC pellets

Feed Temperature: About 130℃

Target Discharge Temperature: About 35℃

Output Requirement: 400 kg/h

Material State: High-temperature pellets with good flowability

Customer Core Requirements

Through preliminary communication and on-site working condition analysis, the customer mainly focuses on the following points:

- High-efficiency cooling to prevent pellet adhesion and deformation. high temperature pellet cooling, pellet deformation prevention. cooling system

- Stable vertical lifting without damaging the pellet shape. vertical vibrating elevator. stable vertical pellet lifting equipment

- Smooth connection with the existing production line, continuous pellet processing

- Screening before lifting to remove abnormal pellets. Pellet screening equipment, linear vibrating screen for pellet screening

Equipment must run stably and meet long-term continuous production, a continuous high-temperature pellet cooling system

Our Solution

Based on the characteristics of the customer’s material and output requirements, we provided an integrated screening, cooling, and conveying solution with the following configuration:

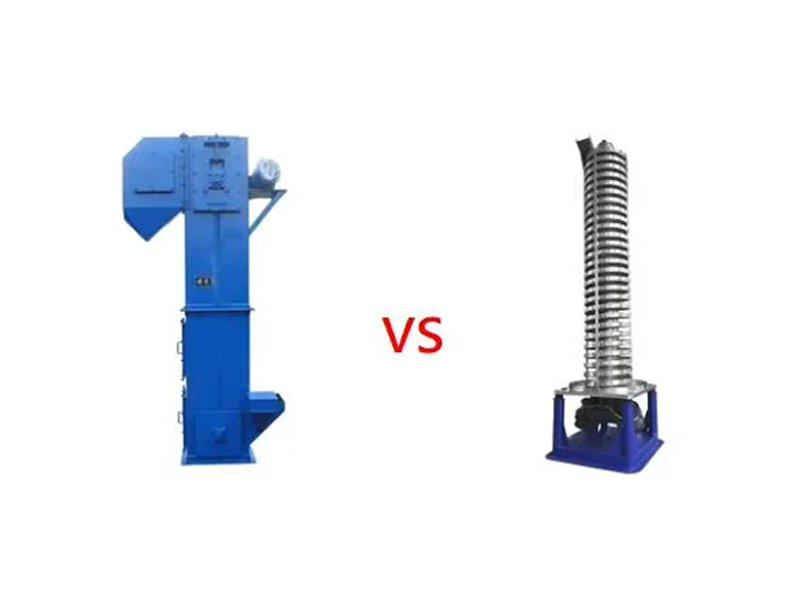

1. Water Cooled and Air Cooled Vertical Vibrating Elevator

Equipment Type: Water-cooled and air-cooled composite Vertical Vibrating Elevator

Recommended Diameter: 500 mm to meet 400 kg/h output

Customer Choice: 800 mm large size

Net Lifting Height: 3.5 m

Cooling Method Description:

- Built-in water cooling system quickly removes pellet heat water cooled and air-cooled vibrating elevator

- Combined with an air cooling structure for uniform secondary cooling, high high-efficiency plastic pellet cooling system

Solution Advantages:

- Lifting and cooling are completed simultaneously, saving space

- The gentle vibrating conveying method does not damage pellets, pellet deformation prevention cooling system

- High cooling efficiency, stable discharge temperature, and plastic granule cooling

- Suitable for high-temperature plastic pellets and color masterbatch continuous production lines, color masterbatch cooling and conveying system

- Simple structure, suitable for long-term operation

Product Information: Standard Vertical Vibrating Spiral Elevators

2. Linear Vibrating Screen

Installation Position: Front end of the vertical vibrating elevator

Screen Plate Type: Perforated plate

Screen Hole Size: 8 / 2 mm

Equipment Model: SYZ-515 Linear Vibrating Screen

Main Functions:

- Remove oversized or irregular pellets. screening and conveying equipment for plastic granules

- Ensure uniform pellet size entering the elevator

- Improve cooling effect and overall system stability, plastic granule conveying

Product Information: Linear Vibrating Screen

Implementation and Communication Process

- Confirm material characteristics and temperature range in advance

- Design and calculation of drawings by our professional team based on material temperature, and output customized pellet cooling and conveying solutions

- Provide layout suggestions to optimize on-site space utilization

- Confirm the cooling method and screening accuracy, then finalize the solution

Project Implementation Results

After the equipment was put into operation, the following goals were achieved:

- Material temperature was stably reduced from 130℃ to about 35℃, and high-temperature pellet cooling

- Actual output met and stably ran above 400 kg/h, continuous pellet processing

- Pellets without adhesion or deformation, pellet deformation prevention cooling system

- Stable lifting process and good continuity, stable vertical pellet lifting equipment

- Effectively improved the downstream packaging and conveying efficiency of plastic pellet conveying

Applicable Industries and Material Expansion

This solution is also suitable for the following fields:

- Modified plastic pellets, plastic granule cooling

- Engineering plastic pelletizing industrial plastic granule cooling solution

- PVC, PE, PP, ABS pellets, PVC pellet cooling and conveying line

- Color masterbatch production line, color masterbatch cooling and conveying system

- High-temperature pellet cooling and lifting process, high-efficiency plastic pellet cooling system

Our Service Support Includes

- Solution customization and selection support customized pellet cooling and conveying solutions

- Technical documents and drawings support

- Production line matching and layout suggestions

- Installation and commissioning guidance

- After-sales technical support and maintenance services

If your working conditions have the same problems, you can contact us now. We are a manufacturer with 30+ vibrating screen production lines. Our professional technical team can help you solve any vibrating screen and screening problems. Contact us now for more support.