In the field of industrial screening, Gyratory Screen is an efficient and durable screening equipment widely used in chemical, food, mining and waste treatment industries. It realizes fine grading and screening of materials through unique rotary motion, and compared with traditional vibrating screen, it has the features of large handling capacity, high screening precision and low energy consumption. In this article, we will introduce the working principle of gyratory screen, its features, its application in sand making production line. please read on:

What is Gyratory Screen?

Gyratory screen, also called a gyratory sifter, which is a kind of high efficient screening equipment with high precision and large output, which is usually used for screening and grading of fine materials. It is characterized by better self-cleaning screen effect, long life with high screen utilization rate and good sealing effect. It is widely used in sand and gravel aggregate, chemical industry and new material, metallurgy, metal powder, mineral powder, food, salt, sugar, abrasive, feed and other industries. Through the square swing vibrating screen, the gyratory motion occurring in the exciter is transmitted to the screen surface, so that the material is rapidly dispersed in the front of the screen machine, thus achieving the purpose of efficient screening.

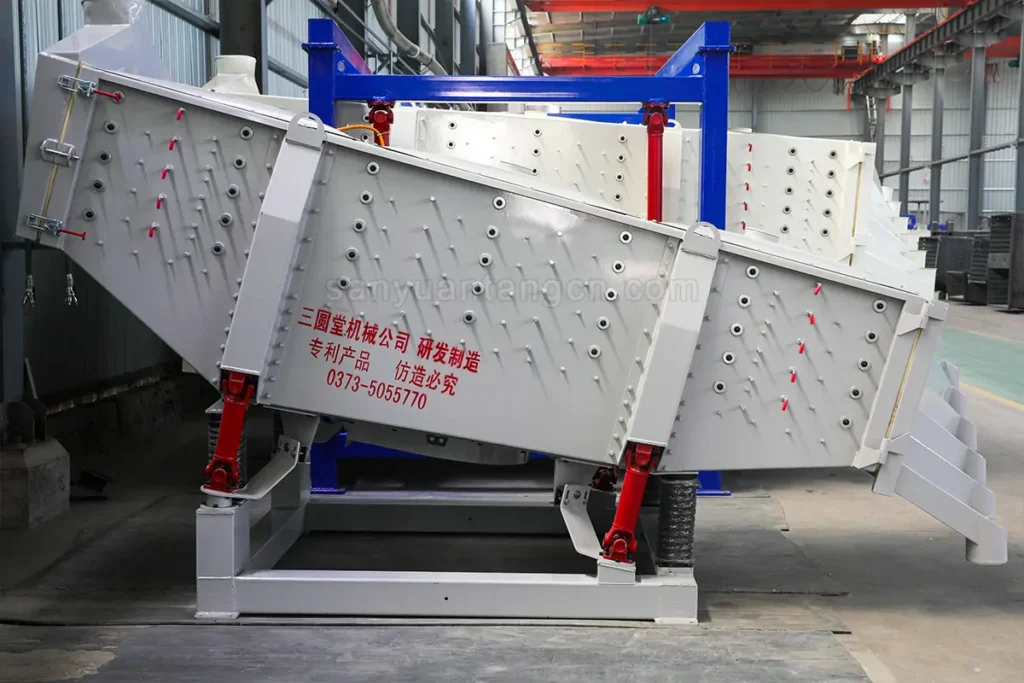

Structures

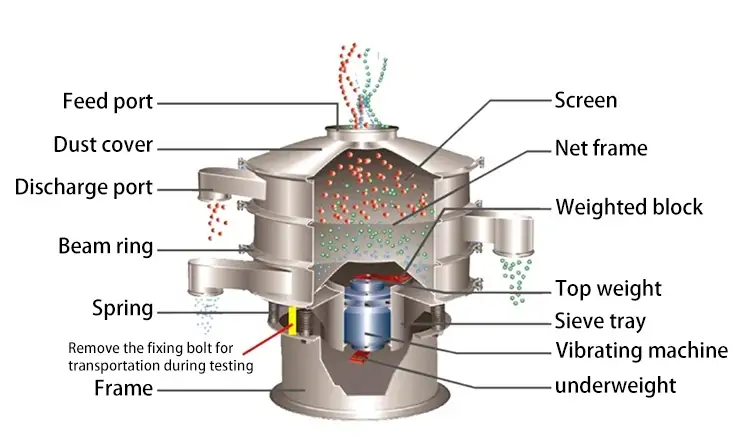

The structure of Gyratory Screen mainly consists of components such as drive device, fabricator, screen box, support frame, driving device, vibration damping device and so on.

Driving device: It includes driver, motor, locking sleeve, locking nut, stop washer and taper sleeve and other components.

Sieve box: includes components such as sieve frame, sieve mesh, sieve grid, spring card and bouncing ball. Therein, the screen frame is fitted with upper and lower screen mesh, the screen mesh is tensioned on the screen grid by spring cards set on the periphery of the screen grid, and the bouncing ball is set in the square of the screen grid.

Working Principle

The screen box of Gyratory screen is reciprocating back and forth under the action of inertia force, and the screen box drives the screen surface to make periodic shaking, so that the materials on the screen surface make plane cyclotron movement with the screen box, during which the materials smaller than the aperture of the screen surface fall through the sieve holes to the lower layer, and become the under-screen material, and the materials larger than the aperture of the screen surface are discharged from the discharge port after continuous tumbling and jumping movement, so as to complete the sieving work.

Types of Gyratory Screen

According to different needs and applications, gyratory screens can be divided into the following types:

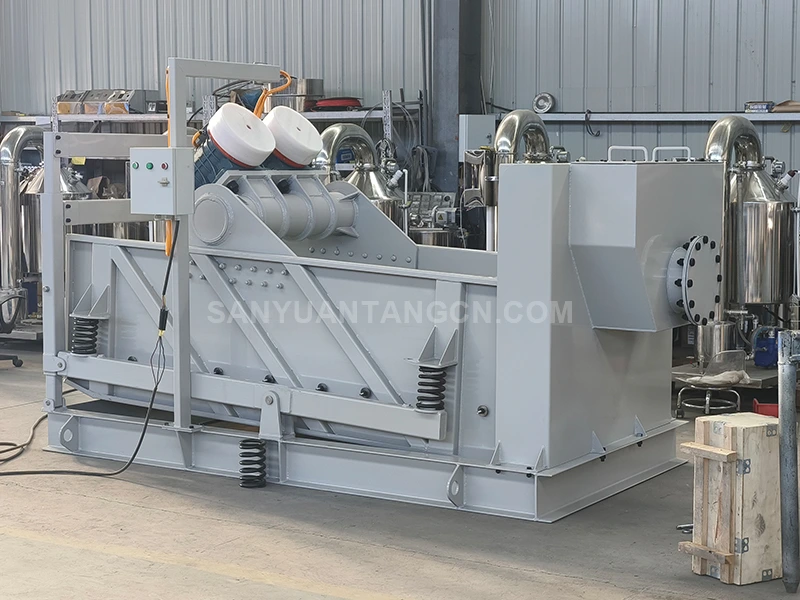

Sing;e Vibration Source (Double-Seven Layer)

Double Vibration Source (Double-Five Layer)

Large-Inclination Swing Probability Vibrating Screen

Linear Swing Vibrating Screen Machine

Features:

- Large electrostatic plastic spraying process, with beautiful, wear-resistant, rust-resistant features.

- Adopt multi-layer grading screen design, a machine divided into two groups, double the output.

- Fully enclosed structure, dust does not fly, screen vibration is small, low noise, in line with environmental protection requirements.

- Flexible screening, the acceleration is 4-5 times lower than ordinary vibrating screen, the service life is improved, thus reducing the maintenance cost.

- Convenient and fast screen change, simple operation.

- Two layers of screen mesh adopts the same aperture, so that the materials screened once can be screened again to achieve higher screening precision.

- Material screening by fine → medium fine → medium → coarse way screening, self-cleaning effect is better.

Use In Sand Production Line

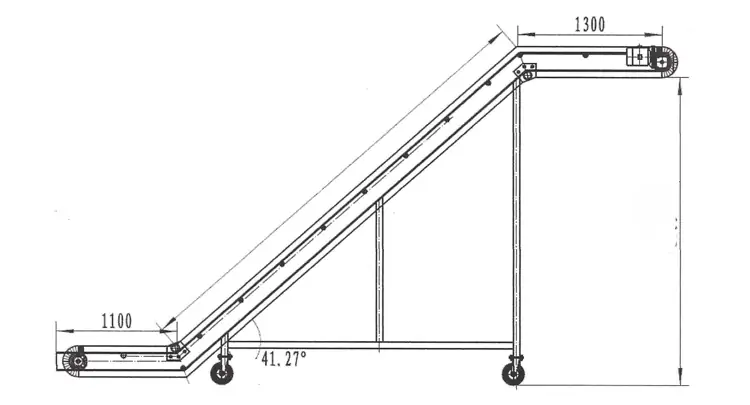

In the sand and gravel aggregate processing line, the Gyratory Screen is usually used in conjunction with bucket elevators, belt conveyors and sand mills, and is the core equipment for screening medium and fine-grained materials (0-50mm). In the crushing and screening process, the Gyratory Screen is often configured in sand mills or fine crushing closed-circuit systems, and is mainly used in the following areas:

- Pre-screening link: 5-10mm coarse screening of the mix after jaw crushing, with a screening efficiency of over 90%.

- Finished product classification: precise separation of 0-5mm mechanism sand, 5-16mm/16-31.5mm crushed stone, by adjusting the screen surface inclination angle (15°-25°) can be adapted to different moisture content materials.

Silica Sand Production Line

Quartz Sand Production Line

Quartz Sand Production Line

Quartz Sand Sieving

It adopts double-deck modular screen box design, supports rapid replacement of polyurethane screen mesh, meets the screening requirements of different hardness materials such as basalt, river pebbles, etc., and can realize continuous and stable operation in large sand and gravel production lines with an hourly output of more than 500 tons.

Conclusion

In summary, the Gyratory Screen is an efficient and reliable screening solution. Compared with traditional vibrating screens, it performs better in terms of anti-clogging holes, low noise, long service life and ease of maintenance, and is especially suitable for wet viscous materials, fine classification and large-scale continuous production scenarios. If you’re looking for a high-capacity, low-maintenance, long-life screening machine, the Gyratory Screen is the ideal choice. Consult with Sanyuntang today for a customized screening solution!