gyratory screen, also known as a gyratory sifter or gyratory separator, is mainly used for grading or screening sand materials, with the characteristics of high screening accuracy and large output. The gyratory screen is widely used in the precise screening and grading process of materials in chemical, metallurgical, ceramsite, non-ferrous metals, non-ferrous metals, grain, food, abrasives, mining, and other industries.

- Model: FYBS-1536 , FYBS-2040

- Material: Carbon Steel

- Mesh Size: 2-200 mesh

- Layers: 1-10 layers

- Motor Power: 5.5kW/7.5 kW

- Capacity: 100kg – 25 Tons/hour

- Customized: Acceptable

Price: $14800.0 – 23400.0 / Set

Working Principle

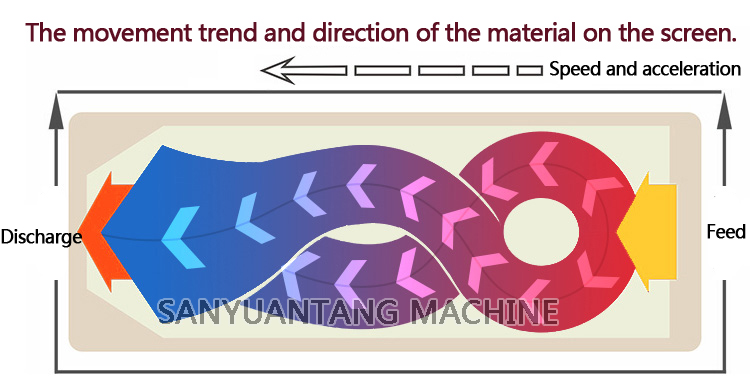

After the rectangular gyratory screen is started, the shaking body of the screen machine, that is, the screen box, reciprocates back and forth under the action of inertial force. The screen box drives the screen surface to shake periodically so that the materials on the screen surface make directional jumping movements together with the screen box.

During this period, materials smaller than the screen pore size fall to the lower layer through the sieve holes and become under-screen materials. Materials larger than the screen pore size are discharged from the discharge port after continuous rolling and jumping motion, thereby completing the screening work.

Videos

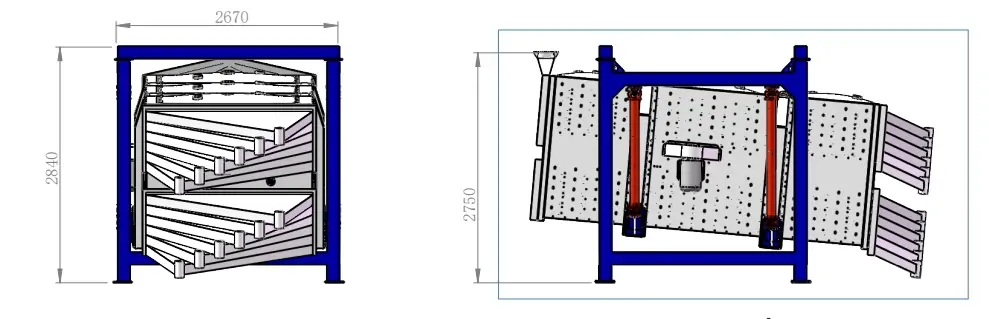

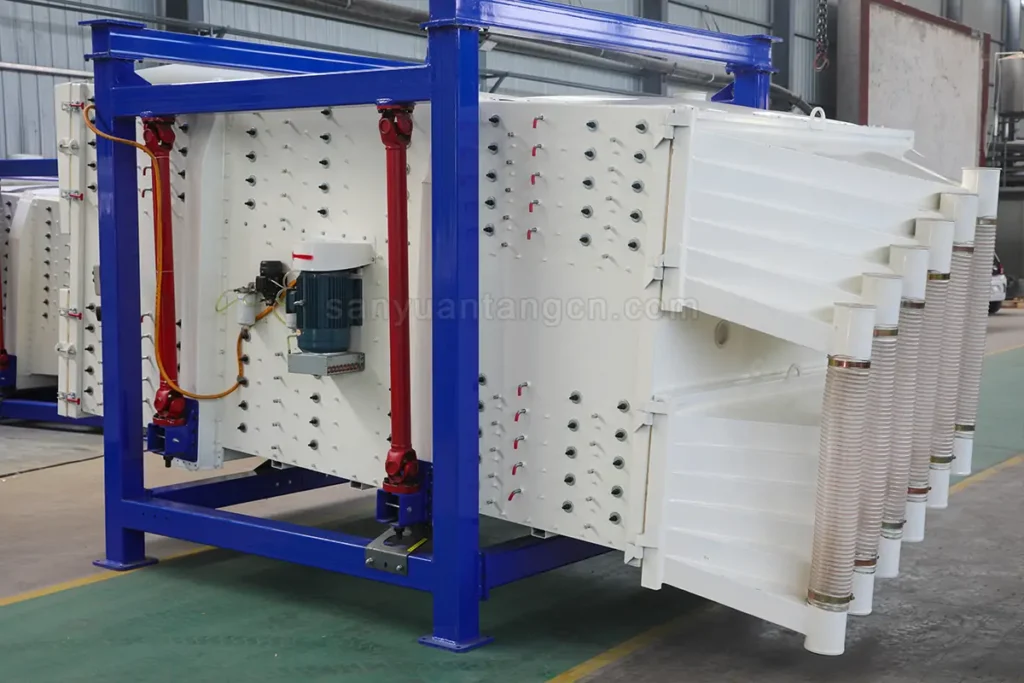

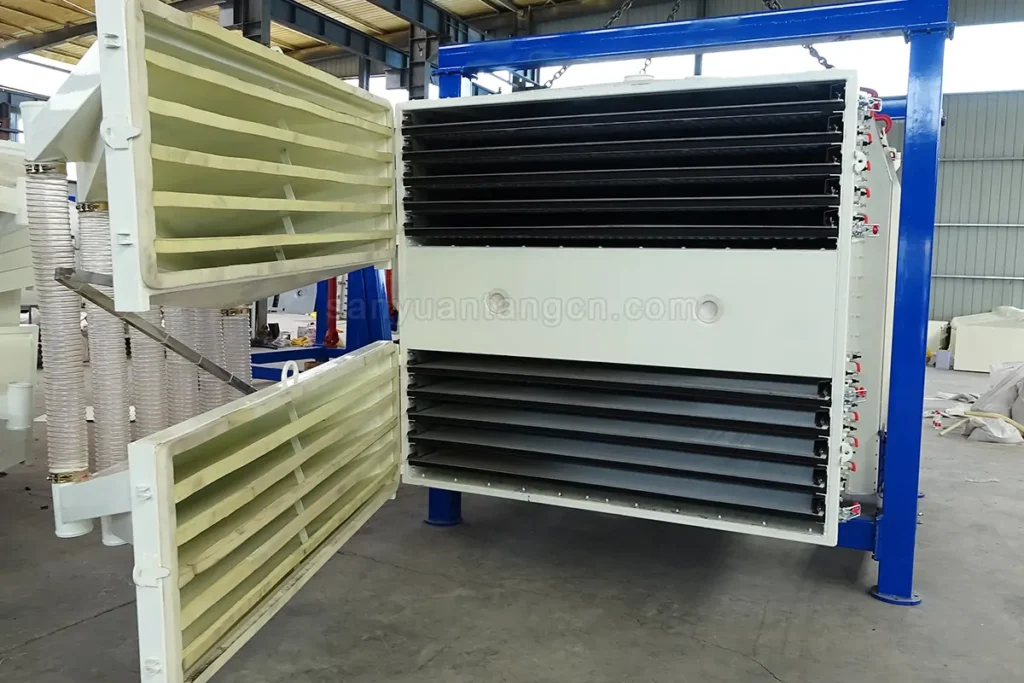

Structures

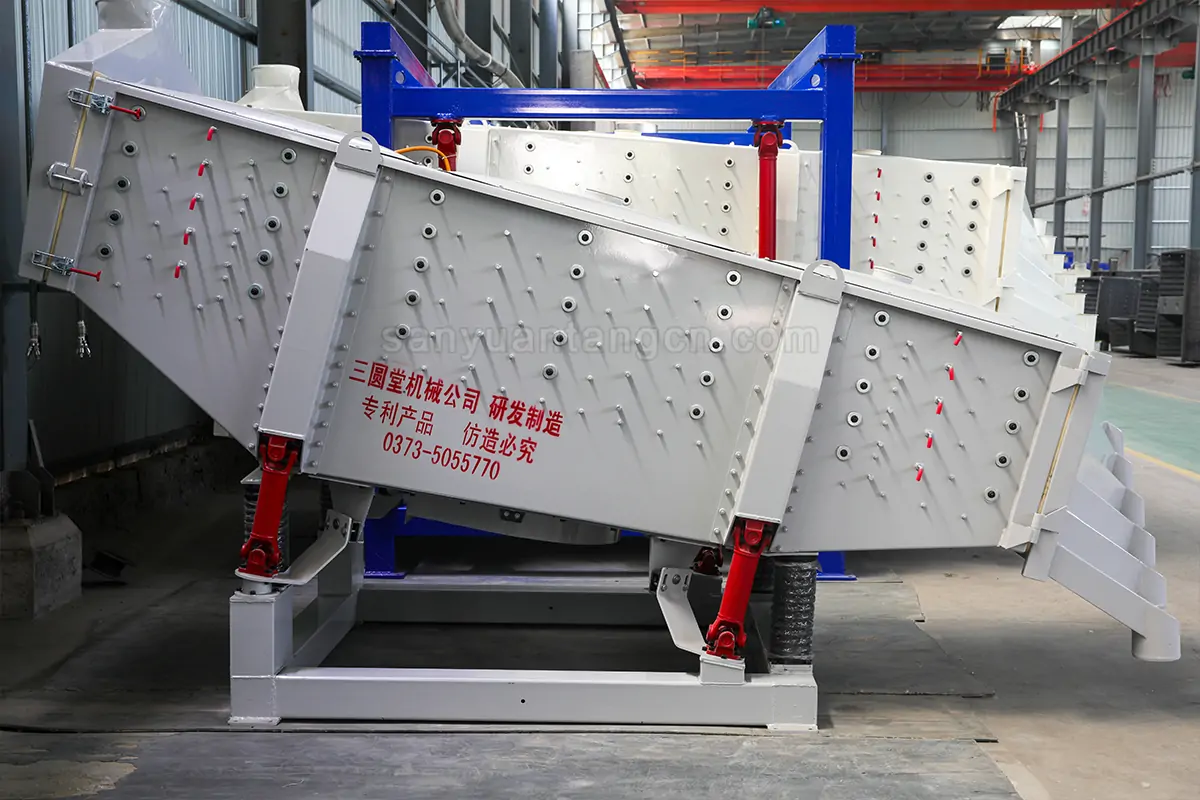

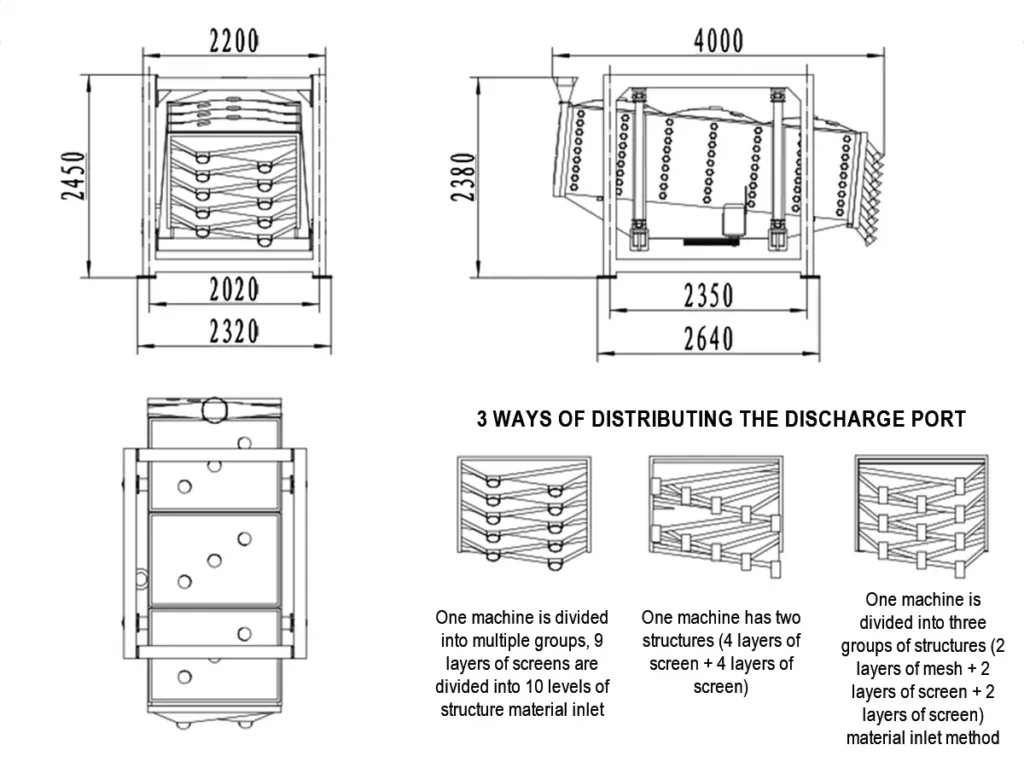

The square gyratory screen is a hanging shaker sieve, mainly comprises a feed port, screen box, drive device, screen frame, support frame, vibration reduction device, discharge port, and other components. The follow is gyratory screen diagram:

- Feeding system: innovative design, using an independent material distribution plate to optimize the uniformity of material distribution; lightweight rear door enhances the front-end swing efficiency, promoting the rapid and uniform spreading of materials on the screen surface.

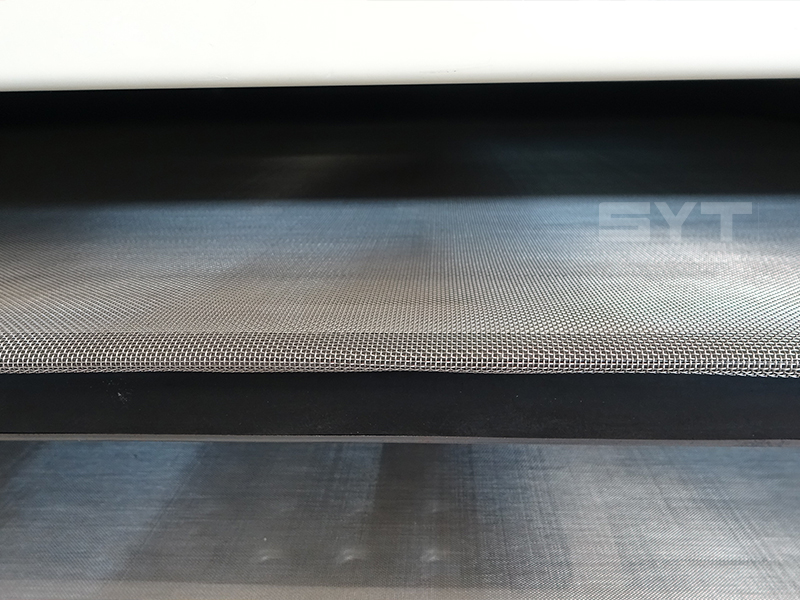

- Screening box: integrated screen frame, equipped with double-layer screen, using spring clip to fasten the edge of the screen to ensure screening accuracy; built-in bouncing ball to enhance material bounce, prevent blockage, and improve screening efficiency.

- Power drive unit: driven by an electric motor, with precision cone sleeve and locking mechanism, stabilize the position of the drive shaft, and achieve efficient and stable power output.

- Flexible connection system: universal shaft is used to connect the screen box, which effectively buffers the impact force during the swing process, ensures the smooth operation of the screen machine, and extends its service life.

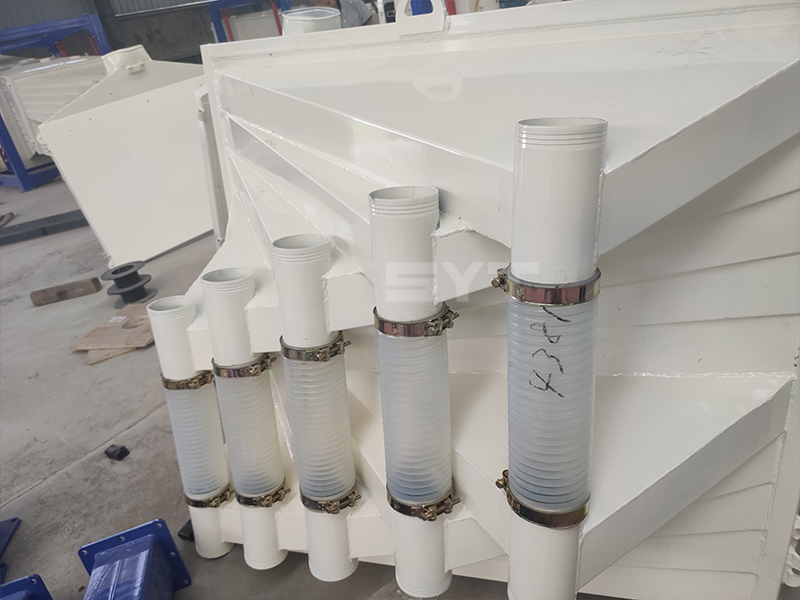

- Flexible discharge design: customized discharge port according to material characteristics, optimized flow control, reduced blockage, and accelerated smooth discharge of materials by adjusting angles, expanding pipe diameters, and other measures.

Details

Application

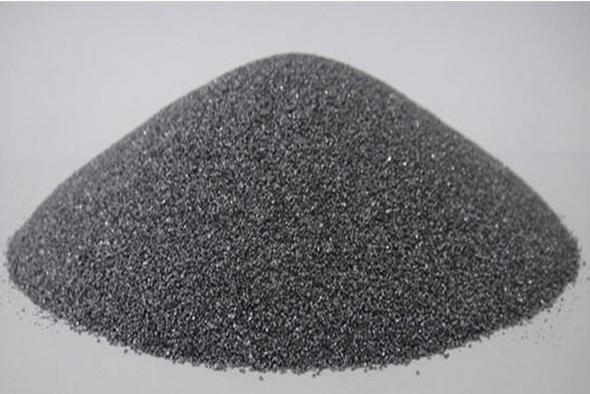

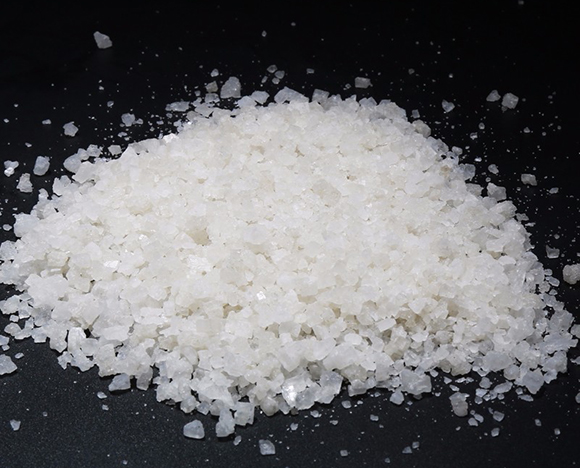

The gyratory screen is mainly used for screening materials such as Quartz sand, silica sand, machine-made sand, fracturing sand, sheet sand, glass sand, ceramic sand, river sand, drying sand, pearl sand, mica powder, garnet, carbon, carburizing agent, calcium carbonate powder (limestone), Petroleum coke, calcined coke, industrial salt, polypropylene, dried mineral powder, talc powder, fertilizer, etc.

Silica Sand

Silica Sand Oil Fracturing Proppant

Oil Fracturing Proppant Ceramic Sand

Ceramic Sand Perlite

Perlite Metal Silicon Powder

Metal Silicon Powder Industry Salt

Industry Salt Cork powder

Cork powder Calcium Carbonate

Calcium Carbonate Soda Ash

Soda Ash

Specifications

| Model | Screen size | Screening area | Screen inclination | Layers | Power | Number of turns | Case travel |

|---|---|---|---|---|---|---|---|

| FYBS1536 | 1.5*3.5 m | 4.5-9 m2 | 5-8 | 1-10 | 5.5 | 180-260 | 25-60 mm |

| FYBS2040 | 2.0*4.0 m | 8-9 m2 | 5-8 | 1-10 | 7.5 | 180-260 | 25-60 mm |

types of gyratory screen

According to the setting mode of vibration source, the gyratory screen can be divided into different types such as middle vibration type, down vibration type, double vibration source type, and single vibration source type. When choosing, it is necessary to comprehensively consider factors such as specific screening requirements, material characteristics, and production environment.

Different vibration modes

Middle-vibration square gyratory screen

Features: The vibration source of the middle-vibration square gyratory screen is usually located in the middle or near the center of the screen. This design allows the vibration force to be transmitted to each part of the screen surface more evenly, which helps to improve the screening efficiency and utilization of the screen surface.

Application: Suitable for occasions with high requirements for screening efficiency and uniformity, such as fine chemicals, food, and other industries.

Lower-vibration square gyratory screen

Features: The vibration source of the lower-vibration square gyratory screen is located at the bottom or below the screen. This design can reduce the impact of vibration on the upper structure of the screen machine and make the screen machine run more stably. At the same time, since the vibration source is at the bottom, the overall area of the screen surface can be better utilized for screening.

Application: Suitable for occasions with high requirements for screening stability or heavy screening materials, such as mining, metallurgy, and other industries.

different setting of vibration source

Double Vibration Source Square Gyratory Screen:

Features: The double vibration source square gyratory screen sets two or more exciters at different parts of the screen body. By changing the motion trajectory of the screen machine, the material has a relatively short pause state on the screen, thereby improving the screening capacity and accuracy. This type of screen machine usually has higher screening efficiency and a better net cleaning effect.

Application: It is widely used in occasions that require high-precision and large-volume screening, such as chemical, food, metallurgy, and other industries. Especially when the material particle size difference is large or multi-stage screening is required, the double vibration source square swinging screen performs well.

Single Vibration Source Square Gyratory Screen:

Features: The single-vibration source gyratory vibrating screen only sets one vibration source, and the vibration force generated by the vibration source drives the screen body to swing. This type of screen machine has a simple structure and is easy to maintain, but the screening efficiency and accuracy may be slightly inferior to the double-vibration source screen machine.

Application: It is suitable for occasions where the screening requirements are not particularly high or the material particle size distribution is relatively uniform. In some small production lines or laboratories, the single-vibration source square swinging screen is also widely used.

Features

Up to 5 times the output per unit area; accurate to 9 levels of separation, and the screening efficiency is as high as 95%-99%.

Each layer of screen mesh is equipped with a screen mesh anti-clogging cleaning device. The screening machine continuously cleans the mesh mesh under working conditions, and the mesh mesh has almost no clogging.

New technology

The large-scale electrostatic spraying process makes the equipment more beautiful, wear-resistant, and rust-proof.

Longer life

For flexible screening, the acceleration is 4-5 times lower than that of ordinary vibrating screens, and the service life is increased, thereby reducing maintenance costs.

Easy to operate

Network replacement is more convenient, simple to operate, and runs smoothly.

Environmental friendly

Fully enclosed structure, dust does not fly, and the screen machine has small vibration and low noise (less than 75 decibels), which meets environmental protection requirements.

Customer Site

With our rich project experience and excellent technical strength, we have successfully built customized square gyratory screener production lines for many customers, which not only significantly improved the screening efficiency and product quality, but also brought significant economic benefits to customers. The following are pictures of our customer’s on-site feedback: