In the production and recycling processes of the plastics industry, the screening of plastic pellets is of paramount importance. Whether it involves pelletizing virgin material, manufacturing modified plastics, or processing recycled pellets, the selection of plastic pellet screening machines determines product purity, particle size, and the stable operation of subsequent processes. Currently, three main types of plastic pellet screening machines are commonly used in the industry: linear screening machines, rotary vibrating screens, and inline vibratory screens. Let’s explore the performance, application scenarios, and selection recommendations for each type. I hope my suggestions prove helpful.

linear screening machine

linear screening machine Rotary Vibrating Screen

Rotary Vibrating Screen Inline Vibratory Screen

Inline Vibratory Screen

Linear Screening Machine

Working Principle

Dual motors operate synchronously to create a linear material movement trajectory. Material advances uniformly and at a constant speed across the screen surface. Equipped with 1-3 layers of screens, it achieves 2-4 levels of particle size separation. Its quick-release modular screen design accommodates frequent material changes.

Typical Applications:

- Post-granulation plastic grading: In PP/PE pellet production, separates finished pellets into 2-5mm specifications for injection molding, film blowing, and other downstream processes.

- Coarse screening of recycled plastics: For post-shredded PE film recyclates, a linear screening machine first removes large impurities over 10mm and fine powder below 50 mesh, providing efficient raw material for subsequent washing processes.

- Pre-screening of modified plastics: In glass-fiber reinforced PA66 production, a linear screening machine separates inadequately dispersed glass fiber bundles after extrusion pelletization to prevent compromising the mechanical properties of injection-molded parts.

Rotary Vibrating Screen

Working Principle

Vertical vibrating motors with upper and lower eccentric weights induce a “rotate-jump” composite motion on the screen surface. This increases material contact probability with the mesh by over 30% compared to linear screening machines. Combined with a ball-jumping screen-cleaning device, it effectively resolves plastic particle adhesion issues. Its 5-layer screen design enables up to 6-stage particle size classification, with screening accuracy controlled within ±2%.

Typical Applications:

- Precision Grading of Engineering Plastics: In PBT, PC, and other engineering plastic production, granules can be precisely separated into 1.2mm, 1.5mm, and 1.8mm grades.

- Medical-grade plastic purity screening: For PVC infusion tube pellet production, a 304 stainless steel rotary vibrating screen with 100-mesh screens removes minute metallic impurities and black specks.

- Functional masterbatch grading: In color masterbatch manufacturing, the rotary vibrating screen separates 0.8-1.2mm effective pellets from oversized color specks and ultrafine color powders.

Inline Vibratory Screen

Working Principle

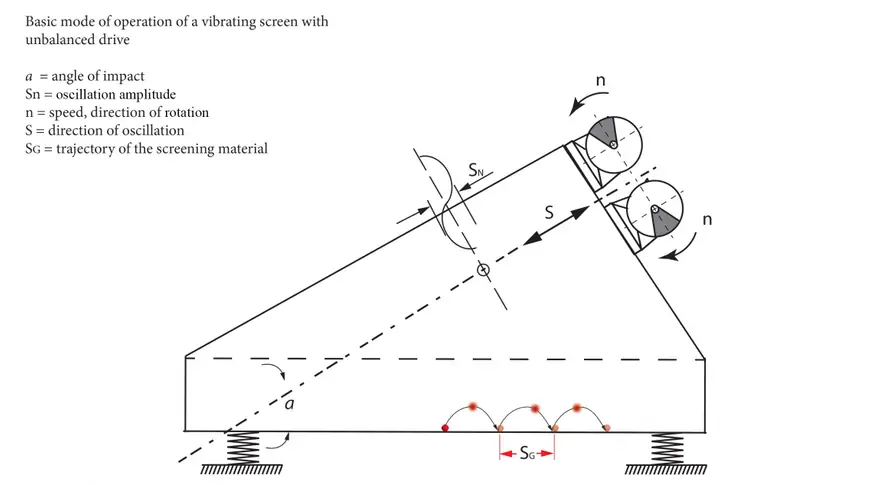

Employing a high-frequency, low-amplitude vibration mode, material residence time on the inclined screen surface is only 2-3 seconds. Combined with large-aperture screens, this enables rapid screening. Particularly suited for rapid impurity removal at the front end of production lines.

Typical Application Scenarios:

- Pre-processing impurity removal in plastic pelletizing lines: During PE pipe pellet production, extruded pellets first pass through an inline vibratory screen to rapidly eliminate clumps and metal debris formed during cooling.

- Rapid screening of bulk plastics: Processing over 20 tons per hour of pellets in PP woven bag raw material production.

- Pre-processing of raw materials in injection molding workshops: For bulk-purchased ABS pellets, an inline vibratory screen performs coarse screening at 12 mesh before feeding into injection molding machines to remove minor agglomerates formed during transportation.

The above outlines the primary principles and common application scenarios of plastic screening equipment. Below are recommendations for machine selection based on our experience.

Recommendations for Selecting Common Plastic Pellet Screening Machines

If your production facility prioritizes high-volume output with stringent requirements for multi-stage grading and batch consistency, the linear screening machine is the preferred choice.

For industries demanding exceptional pellet purity and impurity removal (e.g., functional masterbatches, transparent materials), the rotary vibrating screen outperforms the linear screening machine. Its advantages are particularly pronounced in high-end plastic products where finished appearance is critical.

For inline impurity removal and rapid screening during production—especially to prevent oversized particles or foreign objects from entering subsequent processes—the inline vibratory screen is the optimal solution. Its core function is not grading but ensuring production stability and safety.

The following table provides a comparative overview to assist your selection process.

Core Differences Comparison Chart: Plastic Pellet Screening Machines

| Feature | Linear Screening Machin | Rotary Vibrating Screen | Inline Vibratory Screen |

| Motion Trajectory | Linear, reciprocating | Three-dimensional elliptical/rotary | Primarily vertical |

| Primary Advantage | High capacity, simple structure, durability | High precision, anti-blinding, easy screen changing | Rapid discharge, space-saving, easy cleaning |

| Screening Precision | Medium | High | Medium (mainly for de-trashing) |

| Processing Capacity | High/Large | Medium | High/Large |

| Multi-layer Grading | Excellent | Good | Generally not applicable |

| Suitable Materials | Medium/coarse pellets, dry materials | Fine pellets, sticky, electrostatic-prone materials | Pellets, slurries, materials requiring rapid processing |

| Space Occupation | Rectangular, requires length | Circular, small footprint | Requires height, but small footprint |

Conclusion:

Based on the above data comparison, linear screening machines, rotary vibrating screens, and inline vibratory screens each have distinct advantages. We must select plastic pellet screening machines according to specific production processes and quality requirements. When choosing plastic pellet screening machines, enterprises should fully consider their production scale, product positioning, and requirements for particle size and purity.

As a Chinese manufacturer with over 30 years of experience in designing and producing vibrating screens, we possess professional designers and engineers to address diverse screening challenges. If you encounter any screening issues, contact us now. We will provide assistance promptly.