As an important part of the linear vibrating screen, the screen mesh frame materials have two types: wooden frame and metal frame. In this article, we will explore the characteristics, advantages and disadvantages of each type to help you make an informed decision.

Understanding linear vibrating screen mesh frames

Wooden screen mesh frame

Wooden screen mesh frames are mainly used in the abrasive industry to prevent the friction between materials and carbon steel plates from mixing iron powder in the materials, which affects product quality. Commonly used in smaller linear vibrating screens. Each set of wooden screen mesh frames consists of two stacked frames. It is convenient to replace the screen, and you can also add bouncing balls to increase the mesh penetration rate, effectively prevent the screen from being blocked, and is suitable for screening granular and powdery materials.

Advantages of wooden screen mesh frame:

- Natural affinity: Wood materials may have better affinity for certain specific materials, reducing wear or contamination of materials during screening.

- Cost considerations: Compared with metal screen mesh frames, wooden screen mesh frames may be more economical in initial investment and suitable for projects with limited budgets.

- Environmental adaptability: In specific environments, such as places with proper humidity control, wooden mesh screen frames can operate stably, but attention should be paid to moisture and mildew prevention.

- Durability considerations: Despite the low cost, wooden mesh is relatively less durable, especially when facing high-intensity vibration or corrosive materials, which may require more frequent replacement.

Disadvantages

- It is suitable for fine materials such as powder and granules, but it is not easy to use wooden mesh for large particles or corrosive materials.

- When the wooden mesh is used for a long time, wood chips will fall off, causing these wood chips to mix with the screened materials, which will affect the screening effect of the linear vibrating screen.

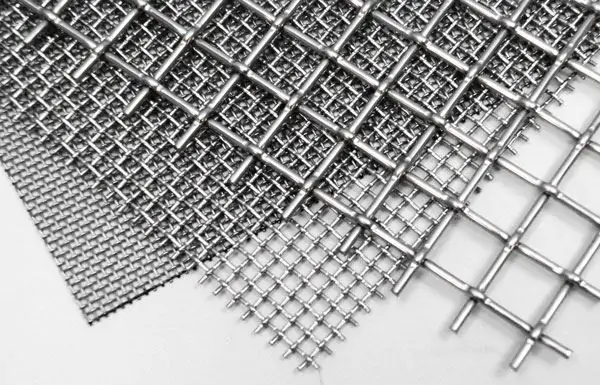

Metal screen mesh frame

The metal screen mesh frame of the linear vibrating screen is usually made of Q235 carbon steel or 304 stainless steel, the main advantages are durability, not easy to break, and large screening area. It is often used to handle larger particles and materials with higher specific gravity.

Advantages of metal Screen Mesh frame

Tighter screen: The metal screen mesh frame has a tighter screen, ensuring higher quality and precision during the screening process.

Corrosion and wear resistance: It has excellent corrosion and wear resistance and is suitable for handling corrosive or abrasive materials.

Easy maintenance: The structure of the metal mesh is usually simple, easy to clean and maintain, and reduces maintenance costs and time.

Customization flexibility: The metal mesh can be precisely customized according to specific screening needs, such as aperture size, screening area, etc., to meet a variety of screening scenarios.

Meet hygiene requirements: For materials in industries such as food and chemical industries that have hygiene requirements and anti-corrosion, stainless steel metal mesh can be selected.

Disadvantages of Metal Screen Mesh frame

High Cost: Metal screen mesh frames are more expensive to manufacture than wooden frames, which is an important factor for businesses with tight budgets.

Complex Replacement: While metal screen mesh frames are more durable and less prone to damage, replacing metal screen mesh frames can be more complicated and time-consuming than wooden frames.

Note:

Be sure to choose a screen with a coarser wire diameter, because the installation of a linear screen is relatively complicated.

- When cutting, the width of the screen should be consistent with the mesh screen mesh frame, and the length must be 50~70mm longer than the mesh frame.

- When installing, the screen must be tightened, because the tension of the screen is an important factor affecting the screening efficiency.

- When adding a net-clearing ball, be sure to consider the screening difficulty and mesh number of the material, and do not install it blindly.

- If the material has a large specific gravity or the mesh number of the screen is high, a support net with a suitable mesh number should be added under the screen. The purpose is to play a supporting role, reduce the pressure of the material on the screening net, and extend its service life.

- After the mesh screen mesh frame is assembled to the screen box as required, remember to extend the extended screen into the corresponding discharge port to avoid mixing.

- When installing the pressure plate, be sure to pay attention to its flatness and tighten it evenly with a highly elastic sponge sealing belt, because this is not only the key to preventing mixed grades, but also an important factor affecting the service life of the screen.

- After installation, a small amount of material should be used to test the screen cloth and screening conditions. If the material is evenly transported forward, the classification is accurate, and there is no mixing, it means that it can be put into use; on the contrary, if there are uneven phenomena such as deviation or accumulation, the flatness and uniformity of the screen surface of the screen machine should be adjusted. If mixed grades occur, check the sealing of the screen and whether it is pressed tightly.

Choosing the Right Screen Mesh frame for Your Linear Vibrating Screen

The choice between wooden and metal screen mesh frames depends on several factors, including material properties, screen mesh, output requirements, and desired precision. Here are some considerations to help you make your decision:

Material Properties

- Fine vs. Coarse: For fine, powdery, or granular materials, a wooden screen mesh frame may be sufficient. However, for larger or more abrasive materials, metal screen mesh frames are recommended due to their durability and strength.

- Corrosive Materials: If you are screening corrosive materials, stainless steel frames are the best choice because they resist corrosion and chemical damage.

Screen Mesh and Output:

- Mesh Size: The desired mesh size will affect the choice of frame. Tighter meshes may benefit more from the rigidity and precision of a metal screen mesh frame.

- Output: High-output applications may require the robustness of a metal screen mesh frame to handle increased loads and maintain long-term efficiency.

Precision Requirements:

- Precision: For industries where precision is critical, such as pharmaceutical or food processing, the tighter screening quality of a metal screen mesh frame ensures better results.

- Regulatory Compliance: Some industries have strict regulations regarding materials and processes. Stainless steel screen mesh frames are often better able to meet these requirements than wooden screen mesh frames.

Conclusion

When choosing a linear vibrating screen mesh frame, you should consider the material properties (such as particle size, humidity, corrosiveness), screening requirements (such as output, accuracy), operating environment (such as humidity, temperature, vibration intensity) and budget. For scenes that need to handle corrosive or highly abrasive materials, metal screen mesh frames are undoubtedly the better choice; for cost-sensitive occasions with milder material properties, wooden screen mesh frames may be an economical choice. At the same time, you also need to pay attention to the maintenance cost and service life of the frame to ensure the long-term stable operation of the screening equipment.