The rotary vibrating screen and inline vibratory screen are common screening equipment, used for screening and classifying materials. However, there are some differences between them, including working principle, structural characteristics, application scope, price, and so on.

Appearance

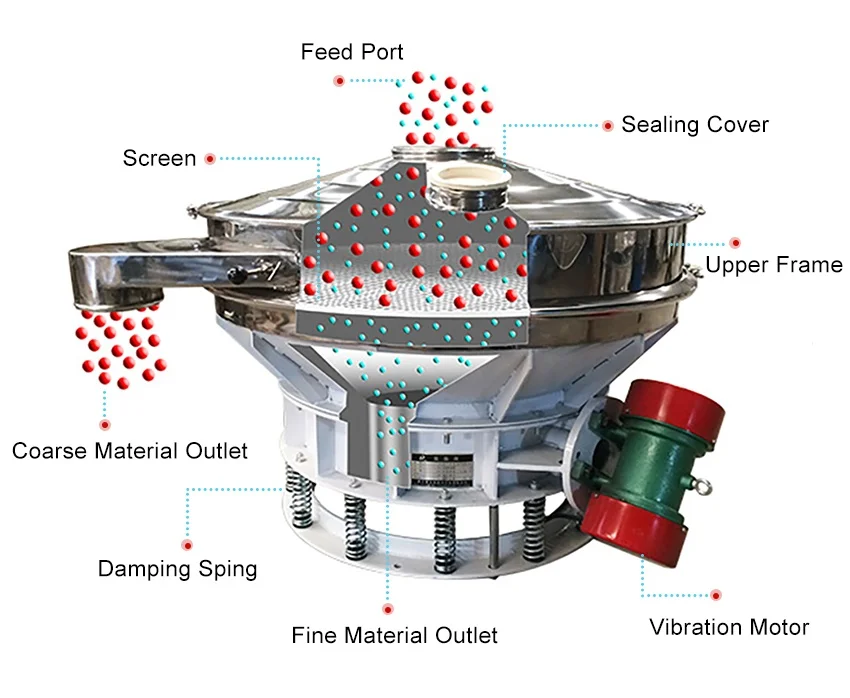

The rotary vibrating screen and self-discharge screen are very similar in appearance, both are round sieves. But the motor of the rotary vibrating screen is a vertical vibrating motor, the equipment can do 1-5 layers of 6 levels of screening, usually using three layers of screen mesh. The rotary vibration sieve screen can be as fine as 500 mesh, for the fine materials below 60 mesh screening effect is better than the inline vibratory screen.

The inline vibratory screen adopts a horizontal vibration motor, according to the demand can choose a single-side motor or double-side motor. Inline vibratory screens commonly use mesh 12 mesh, 20 mesh, 24 mesh, 30 mesh, 40 mesh, and 60 mesh, usually using a single layer of screen mesh for material screening.

Structure

There are also some differences in the structural characteristics of rotary vibrating screens and inline vibratory screens. Rotary screens are usually arranged horizontally and consist of a screen box, a vibrator, and a screen surface. The vibrator makes the screen box and screen surface vibrate by generating vibration force.

The inline vibratory screen is usually arranged vertically, and the screen surface consists of multi-layer screen panels, with different sizes of holes in each layer.

Working Principle

The working principle of rotary vibrating screen is to use vertical vibrating motor as the excitation source, driven by the motor material in the screen frame to do horizontal, vertical, inclined three-dimensional movement. The materials are separated by the elliptical movement trajectory produced by the vibrating screen machine. After the material is put into the feed port, it is vibrated by the vibration force, and makes linear vibration up and down along the elliptical trajectory. This vibration can make the materials spread, separate and dewater quickly on the screen surface. Rotary vibrating screen is suitable for fine particles and multi-classification screening work.

The working principle of inline vibratory screen is to double vibration motor as the vibration source, driven by the motor material in the sieve frame to do elliptical movement, rapid and reciprocating to realize the material over the screen action. Through the material on the screen surface under the action of gravity from top to bottom of the linear movement, and screen surface to complete the screening process. After the material is evenly distributed in the upper feeding area, it gradually passes through the screen surface in a downward direction. In this process, the larger particles are blocked by the screen mesh above, while the smaller particles fall through the screen holes to the bottom. Therefore, inline vibratory screens are suitable for screening relatively large particles.

Application

Inline vibratory sieve and rotary vibratory screen in the scope of application is also different.

Rotary vibratory screen can be particles, powder, slurry materials for effective screening work, can be 400 mesh powder materials, 500 mesh slurry materials for effective screening work. Mainly used in chemical industry, food, food, pharmaceuticals and other fine particles and difficult to screen materials screening.

Inline vibratory screen is mainly for a large number of particles, powder materials, coarse screening in addition to impurities. Inline vibratory sieve mesh is larger, can make the material quickly through the screen, can screen 60 mesh powder materials, screening output is more than 4 times the rotary vibration sieve. Inline vibratory screen is suitable for the front-end feeding system of the production line, mainly used for coal, ore, cement and other large particles and materials that are not easy to adhere to the screen.

Mesh Clearing Method

The rotary vibrating screen is equipped with a special bouncing ball clearing device, and the bouncing ball is placed in the lower part of the screen, which is carried by the ball carrier. During the screening process, the bouncing ball produces secondary vibration to clean up the mesh surface to avoid clogging.

Inline vibratory screen general screening are particles, or coarse powder materials, not easy to block the mesh, so generally do not need special mesh clearing device.

Price

The following is the common rotary vibrating screen and inline vibratory screen price list.

From the above, it can be seen that the larger the diameter and power of the vibrating screen, the more expensive it is, so when selecting the type, it should be customized according to the needs of the choice, to avoid wasting the cost due to the selection error. In addition, the price of rotary vibrating screen and inline vibratory sieve is also affected by the material and customization requirements.

1, Material

- Rotary vibrating screen material: stainless steel, carbon steel and plastic.

- Inline vibratory screen material: stainless steel, carbon steel.

Different materials determine the price. The difference between carbon steel and stainless steel is between 100$ and 200$, and plastic is cheaper.

2、Customization

Rotary vibrating screen and inline vibratory screen can choose to customize the number of screen layers, gates, bins and so on. Inline vibratory screen can additionally add brackets and movable wheels. The specific price should be decided according to the customer’s customization requirements.

Conclusion

In short, the advantages of rotary vibrating screen and inline vibratory screen are different, and the selection of suitable screening equipment needs to be decided according to the characteristics of the material, particle size and production requirements. If you want to know more, please feel free to contact us.