Vibrating screening equipment is widely used in mining, mineral processing, coal preparation, building materials, and chemical industries, and its performance directly affects production efficiency and economic benefits. Due to the complexity of vibrating screens, the same failure may be caused by multiple factors, and the corresponding solutions may also differ. Therefore, mastering vibrating screen troubleshooting is an essential skill for operators and maintenance engineers to ensure stable operation and reduce downtime.

Based on practical operating experience, this article summarizes common vibrating screen failures and corresponding solutions.

Vibrating Screen Troubleshooting for Exciter Failures

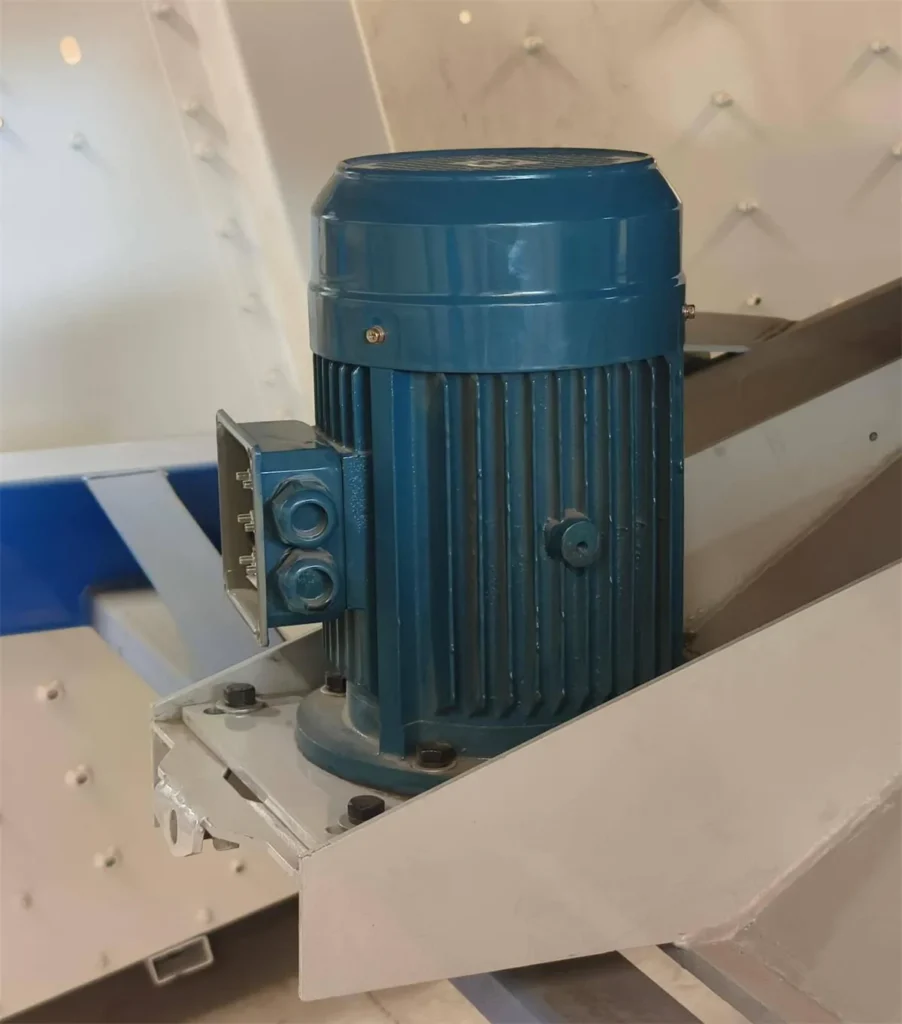

The exciter is the power source of the vibrating screen. It drives the screen body to vibrate through the centrifugal force generated by the rotation of eccentric masses.

During long-term operation, common exciter failures include:

- Heavy-load startup: Production or other equipment failures may cause the screen box to be filled with material. Restarting the exciter under heavy-load conditions can easily damage the universal coupling and other components. Therefore, restarting the vibrating screen under heavy load should be avoided.

- Failure of the damping system: Failure of damping springs or excessive accumulation of material under the screen can cause the damping system to become uncoordinated, which may further damage the exciter. Damping springs should be inspected regularly, deformed or failed springs should be replaced in time, and the stiffness of the springs before and after replacement should remain consistent.

- Installation issues during maintenance: Improper adjustment of exciter clearances during maintenance can lead to errors in the axial and radial clearances between the exciter, motor, and universal coupling, as well as errors in the relative positions of the eccentric blocks. This may cause excessive exciter vibration and result in high temperatures.

During installation, motors of the same model with identical damping characteristics and similar shutdown times should be selected to ensure synchronous operation of the two motors. Before installing the exciter, it must be ensured that the two motors rotate in opposite directions. The motor and exciter must be located in the same vertical plane. Especially during maintenance, for a pair of exciters used simultaneously, the masses of the matched eccentric wheels must remain consistent.

Structural Cracks of Vibrating Screens

During operation, the screen frame vibrates continuously and is subjected to bending fatigue, which can easily cause local deformation or cracking of the screen frame and side plates. The main reasons include:

- Unreasonable screen frame design: The design of the screen frame should take strength and rigidity into consideration to avoid structures that are too thin or too weak.

- Improper material selection: Selecting appropriate materials can improve the durability of the screen frame.

- Manufacturing process issues: Improper welding, heat treatment, and other manufacturing processes can also lead to deformation of the screen frame.

In actual maintenance, if cracks are mostly concentrated at weld seams or connection areas, they are often more closely related to manufacturing processes and welding quality.

A Common Issue in Vibrating Screen Troubleshooting

Bearing overheating is one of the common problems of vibrating screens.

Possible causes include:

- Poor lubrication: Insufficient bearing lubrication or improper selection of lubricating oil.

- Cooling system failure: Problems with cooling fans or cooling liquid systems.

- Bearing damage: Bearing wear or damage increases frictional heat.

For bearing overheating issues, maintenance should prioritize checking the following: regularly inspect bearing lubrication conditions and replace lubricating oil in time; check whether the cooling system is operating normally; regularly inspect bearing wear and replace damaged bearings in time.

Other Common Failures

In addition to the above issues, vibrating screens may also experience the following problems:

- Failure of damping springs: Spring failure can cause unstable operation of the vibrating screen.

- Aging of sealing components: Aging seals may result in oil or water leakage.

- Electrical problems: Failures of motors or control circuits.

Solutions:

Regularly inspect damping springs and sealing components, replace aged seals in time, and inspect the electrical system to ensure proper operation of motors and control circuits.

Precautions for Exciter Disassembly and Maintenance

When disassembling the exciter, the following points should be noted:

- Disassembly environment: Disassembly and assembly should be carried out in a clean environment to prevent dust and impurities from entering the bearing interior.

- Component cleaning: All components must be thoroughly cleaned and burrs removed. Bearings should not be directly struck on the inner or outer rings.

- Lubrication: Before assembly, all mating surfaces should be coated with lubricating oil, such as lithium-based grease.

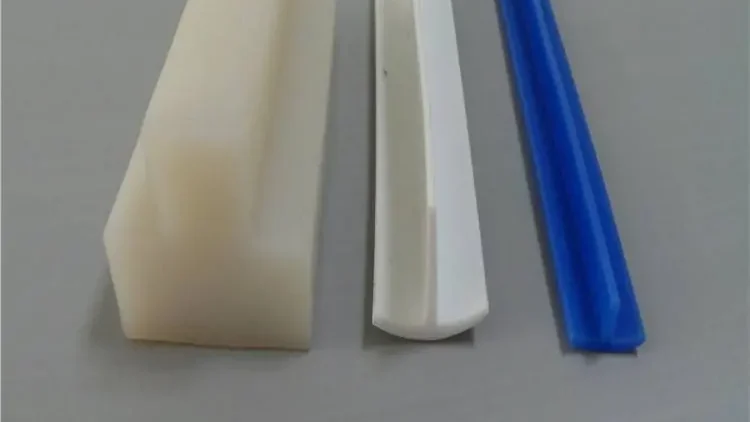

- Seal inspection: Carefully inspect sealing rings and replace them promptly if aging or damage is found.

- Bolt tightening: Add an appropriate amount of specified lubricating grease such as lithium-based grease. When assembling Y-type sealing rings, pay attention to keeping the end face facing inward. All bolts should be tightened according to specifications. During the initial installation period, bolts should be tightened every one to two days for at least three consecutive times, and thereafter inspected every two days.

By applying systematic vibrating screen troubleshooting methods, operators can significantly improve screening efficiency, reduce unplanned downtime, and avoid repeated failures caused by improper maintenance practices, ultimately extending equipment service life.

If you require additional technical support, please contact our expert team to resolve further issues for you.

Email: info@sanyuantang.com

Phone: +86-18639095165