Are you seeking to optimize your material screening operations in Australia? Look no further than vibrating screen for sale Australia. These excellent screening equipment have revolutionized industries nationwide, offering unparalleled efficiency and productivity. In this article, we’ll delve into the benefits of vibrating screens and why they’re a must-have for businesses in Australia.

Table of Contents

Why Choose Vibrating Screen for Sale Australia?

Vibrating screening machines have become the go-to solution for sorting, classifying, and separating materials in various industries. It has the following characteristics:

Enhanced Efficiency: Vibrating screens streamline material processing by efficiently separating particles based on size, shape, and density. This leads to increased throughput and reduced processing times, ultimately boosting productivity.

Versatility: Whether you’re in mining, construction, recycling, or agriculture, vibrating screens cater to a wide range of applications. From sorting aggregates to classifying minerals, these screens adapt to diverse industry needs with ease.

Improved Quality: By ensuring uniformity in particle size and eliminating impurities, vibrating screens contribute to higher-quality end products. This is particularly crucial in industries like construction and agriculture, where product consistency is paramount.

Cost Savings: Investing in vibrating screens for sale in Australia is a smart financial move. Their efficient operation leads to lower energy consumption and reduced maintenance costs, translating to long-term business savings.

Types of Vibrating Screens for Sale Australia

The types of vibrating screens suit different industry applications. The following are some common vibrating screen types, features, and applications:

Gyratory Vibrating Screen

The gyratory vibrating screen uses a specific reciprocating rotary motion mode and a low-inclined screen surface to allow materials to pass through the screen surface quickly, with a large screening area and high throughput. 1-9 layer classification design, 90-99% screening accuracy, the output can reach 3 tons-15 tons/hour, low noise, low energy consumption, to meet the needs of large-capacity and high-precision industrial screening.

Application: The square gyratory vibrating screen is widely used in the mining and mineral industries, mainly for screening and grading carbon, quartz sand, machine-made sand, fracturing sand and other materials.

Linear Vibrating Screen

Linear vibrating screens use a linear motion trajectory, have high screening efficiency, and can process a variety of materials, including dry, wet, coarse, and fine particles. Compared with other types of vibrating screens, linear vibrating screens have a simple design, fewer moving parts, and simple maintenance, thereby reducing downtime and operating costs.

Application: Linear vibrating screens are widely used in mining and quarrying operations to screen and sieve a variety of materials, including ores, aggregates, and minerals.

Tumbler Screening Machine

The tumbler screening machine simulates the manual screening action and process of human beings, performs three-dimensional circular motion, and cleverly combines the screening (planar circular motion) and the winnowing (upward parabolic motion). It has both circular motion and upward arc motion, so the circular swing screen has the characteristics of high screening accuracy, high efficiency, large output (up to 5-10 times that of ordinary vibrating screens), and long screen life. It can easily complete the screening process of large output and high density.

Application: The tumbler screening machine is often used for various fine powders and micro-particle powder materials within the range of ultra-fine metal powders, and is more suitable for materials that are difficult to handle by ordinary vibrating screens. Such as flour, salt, graphite and other spherical, cylindrical, flake, and even irregular shapes that are easy to block the net and require precise screening.

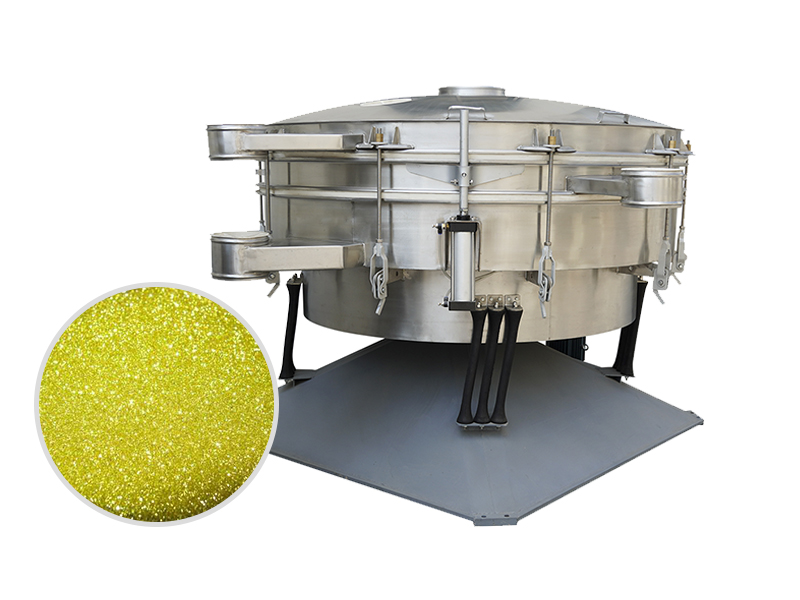

Rotary Vibrating Screen

The rotary vibrating screens use a circular motion trajectory, which can efficiently screen materials in all directions. Rotary vibrating screens provide multi-layer configurations, which can screen multiple particle sizes simultaneously and effectively separate fine powders and oversized materials. Adjustable amplitude and speed: Users can adjust the amplitude and speed of the rotary motion to flexibly optimize the screening process for different materials and applications.

Application: Rotary vibrating screens are widely used in food processing, chemical industry, pharmaceuticals, minerals and mining, ceramics, and powder industries to screen and grade powder, particles, and liquid, effectively improving production efficiency and quality control.

Each type of vibrating screen has unique advantages, designed to meet the screening requirements such as capacity, efficiency, and particle size. By understanding the characteristics and applications of each type, you can choose the most suitable vibrating screen to match your production needs.

How to select a suitable vibrating screen?

Before buying a vibrating screen, keep an eye out for the following features to ensure you’re getting the best value for your investment:

- Screen Size and Capacity: Choose a vibrating screen with the right dimensions and capacity to meet your production requirements.

- Mesh Configuration: Opt for screens with customizable mesh configurations to suit the specific characteristics of your materials.

- Vibration Mechanism: Look for screens equipped with reliable vibration mechanisms that deliver consistent performance and minimal downtime.

- Durability: Invest in vibrating screens made from robust materials that can withstand the harsh conditions of Australian industries.

Ready to take your material processing operations to the next level? Explore the wide selection of vibrating screens available from reputable suppliers and manufacturers across Australia. Whether you prefer to buy new or used equipment, there’s a vibrating screen solution to suit your needs and budget.

Conclusion: Increase productivity and efficiency with vibrating screens

In the competitive landscape of Australian industries, efficiency is key to staying ahead of the curve. With vibrating screens, your businesses can unlock new levels of efficiency, productivity, and quality in their material processing operations. Don’t miss out on the opportunity to optimize your processes and maximize your bottom line with these versatile and reliable devices.

Ready to experience the benefits of a vibrating screen for sale in Australia? Contact [Sanyuantang Machinery] today to explore our range of high-quality solutions tailored to your industry needs.