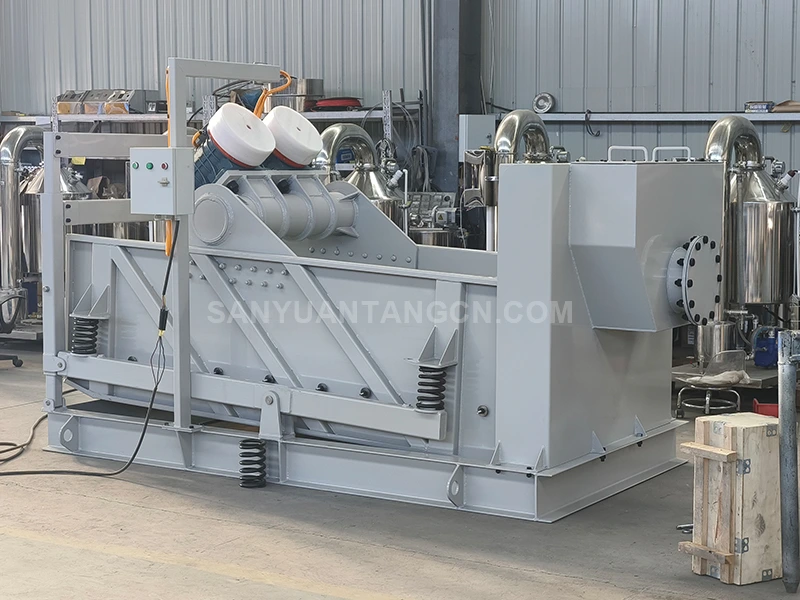

Dewatering vibrating screen is mainly used for dewatering and particle size grading of wet sand in sand production line, which can quickly remove water through high-frequency vibration and inclined screen surface, reduce the moisture content of the finished sand, and meanwhile separate the particles of different particle sizes, so that the finished product meets the standard of particle size, and improve the efficiency of subsequent drying or storage. With a compact structure and large handling capacity, it is suitable for the wet sand process, effectively optimizing the production process and reducing energy consumption.

Today, we are going to talk about the advantages of the dewatering vibrating screen in the industry. At the same time, we will also show you its advantages through its working performance in the sand-making production line.

First, let’s talk about its advantages:

Advantages of dewatering vibrating screen

1. Efficient dewatering performance

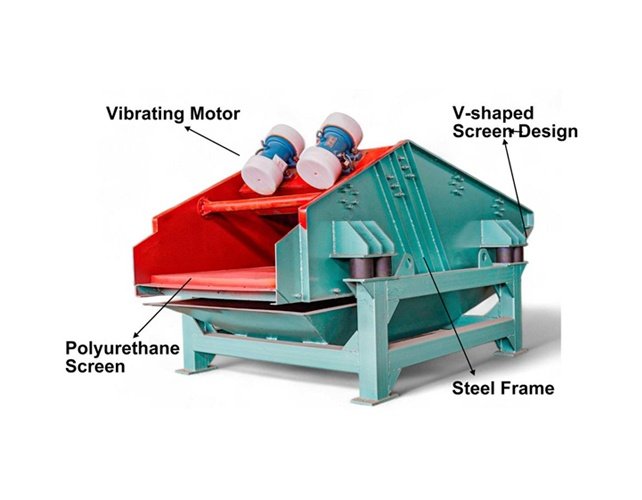

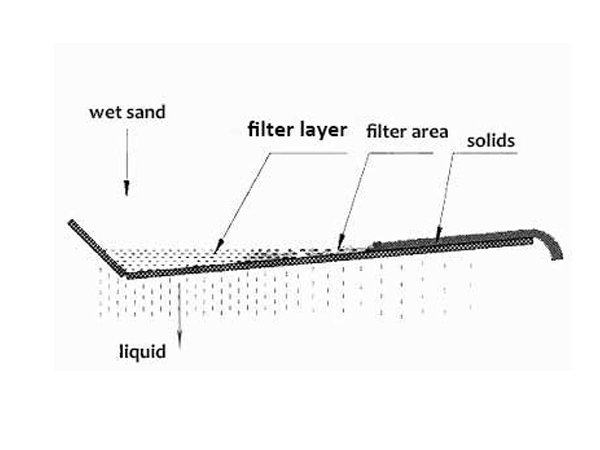

The dewatering vibrating screen adopts high-frequency vibration equipment and a multi-layer polyurethane screen, with a processing capacity of 10-30t/h. Optimizing the vibration trajectory can reduce the moisture content of a single dehydration by 30-50%, so that the moisture content of the product is within the standard. Compared with the traditional natural dehydration method, the processing efficiency is increased by more than 20 times.

2. Energy saving and environmental protection

The equipment is equipped with a high-efficiency vibration motor (power 7.5-45kW), and the energy consumption per ton of processing is only 0.5-1.2kWh. Equipped with a three-stage water circulation system, the water recycling rate is more than 85%, and the suspended solids content (SS value) of the discharged water is <50mg/L, which meets the GB8978-1996 emission standard. The whole machine adopts a vibration isolation design, and the operating noise is controlled below 75dB(A).

3. Wide application of materials

The material particle size range can be processed from 0.045-25mm, suitable for various materials with Mohs hardness ≤7.5. The specially designed anti-blocking screen and the bouncing ball cleaning device can effectively handle sticky materials with a viscosity of ≤5000cP. The amplitude (2-10mm) and vibration frequency (0-3000rpm) can be freely adjusted.

4. Intelligent control system

The PLC automatic control system can be optionally equipped to monitor the moisture content of the material in real time (accuracy ±0.5%) and automatically adjust the feed amount and vibration parameters. Equipped with a fault self-diagnosis system, the life monitoring accuracy of key components (bearings, screens, etc.) is more than 95%.

5. Durable and economical advantages

The whole machine adopts Q345B steel structure frame, and the screen uses polyurethane + silicon carbide composite material, with a service life of 8000 hours. The vibration motor bearing adopts an excellent brand with an estimated life of 10,000 hours. The maintenance cost is only 0.3 yuan/ton, which is more than 60% lower than that of centrifugal dehydration equipment.

Technical Parameter Comparison

| Indicator | This Equipment | Traditional Filter Press | Centrifugal Dewatering Machine |

| Processing Capacity (t/h) | 10-30 | 5-15 | 8-20 |

| Product Moisture Content (%) | 10-15 | 8-12 | 15-20 |

| Energy Consumption per Ton (kWh) | 0.5-1.2 | 1.8-2.5 | 1.2-1.8 |

| Maintenance Cost (¥/ton) | 0.3 | 0.8 | 0.7 |

| Noise Level (dB) | ≤75 | ≤85 | ≤80 |

Through the above data, we can clearly know that the dewatering vibrating screen directly improves our work efficiency. At the same time, it not only improves efficiency but also saves a lot of costs. At the same time, it calls for environmental protection and is also one of the mainstream equipment in the future trend. Our company has more than 30 years of vibration screening technology and equipment. We have rich experience to solve vibration screening solutions for you. Come and contact us to join us!

Next, I will tell you about its application and advantages in specific industries. Today, we will take sand production as an example. Let’s follow us to learn about it.

The role and advantages of dewatering vibrating screen in sand production

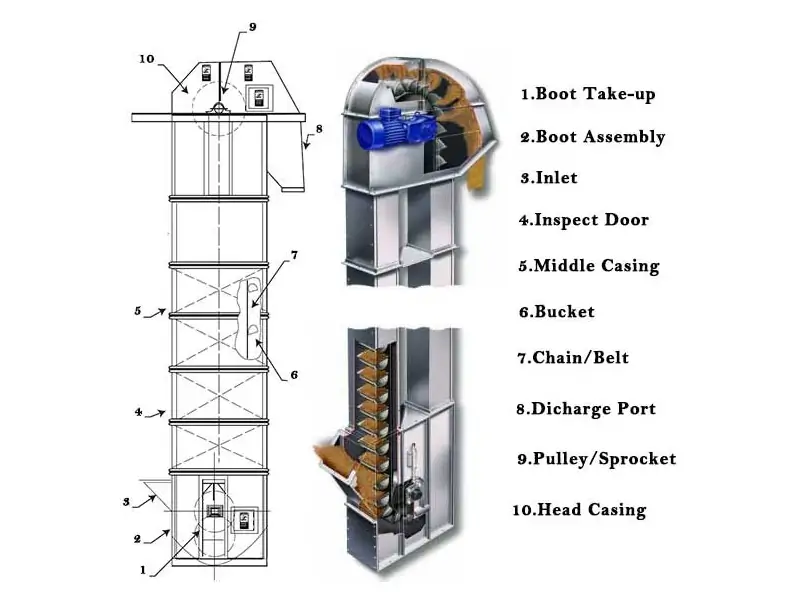

In the sand production line, the dewatering screen (dewatering vibrating screen) is a key solid-liquid separation equipment, mainly used for sand and gravel dewatering, fine sand recovery and sewage purification in the wet sand making process. In the wet sand making process, after the sand and gravel are crushed and washed, they will carry a lot of water (usually 15%~30% moisture content). Direct stacking or loading will lead to high transportation costs, affect the concrete mix ratio, and fine sand loss.

The role of the dewatering vibrating screen:

- Reducing the moisture content of sand (can be reduced to 10%~15%, easy to transport and store).

- Recovering fine sand (reducing the loss of 0.075~0.3 mm fine sand and increasing production).

- Purifying sewage (the separated water can be recycled to reduce wastewater discharge).

1. Economic Benefit Comparison (Annual Processing Capacity: 500,000 tons of sand and gravel)

| Cost Item | Dewatering Vibrating Screen | Traditional Filter Press | Centrifugal Dewatering Machine | Savings Effect |

| Equipment Investment ($) | 65,000-85,000 | 115,000-170,000 | 100,000-145,000 | Save 35-50% |

| Electricity Cost ($/year) | 25,000-35,000 | 70,000-90,000 | 50,000-65,000 | Save 55-60% |

| Labor Cost ($/year) | 4,000-7,000 | 11,000-17,000 | 8,000-13,000 | Reduce 50% |

| Maintenance ($/year) | 6,000-8,500 | 17,000-25,000 | 13,000-20,000 | Save 60-65% |

| Fine Sand Loss (tons/year) | <500 | 3,000-5,000 | 1,500-2,500 | Recover 2,500+ more tons |

| Water Consumption (m³/year) | 8,000 | 25,000 | 15,000 | Save 17,000m³ |

| Annual Total Cost | 100,000-130,000 | 215,000-310,000 | 170,000-240,000 | Annual Savings: $115,000-180,000 |

2.Technical Performance Advantages

| Key Indicator | Dewatering Vibrating Screen | Industry Average | Advantage Margin |

| Processing Capacity | 30-50 t/h | 15-25 t/h | +100% |

| Energy Consumption | 0.6 kWh/t | 2.2 kWh/t | -72% |

| Moisture Content | 10-12% | 15-18% | 5-6 percentage points lower |

| Fine Sand Recovery Rate | 90-95% | 40-60% | +50% |

| Labor Requirement | 1 person | 2-3 persons | 1-2 persons reduction |

| Floor Space | 160-215 ft² | 320-430 ft² | -50% |

By comparing the above two sets of data, we can directly understand the performance of the dewatering vibrating screen in the sand production line. It can not only significantly improve work efficiency, but also save a lot of costs for us. If you have any questions, you can contact us now, and our team will provide you with high-quality vibration screening treatment solutions.

As an efficient equipment in the field of industrial screening, the dewatering vibrating screen has shown significant advantages in scenarios such as sand and gravel production, tailings treatment, and sludge dewatering. Its characteristics of efficient dewatering, energy saving and environmental protection, intelligent control, and durable economy can not only greatly improve production efficiency, but also save a lot of operating costs for enterprises. At the same time, it meets environmental protection standards and is the mainstream equipment for future industrial development.

Xinxiang Sanyuantang Machinery Co., Ltd. relies on more than 30 years of technical accumulation to provide you with customized dewatering screen solutions. Whether it is sand and gravel production or other industrial needs, our professional team will provide you with all-around support.

Contact us to get exclusive solutions, so that efficiency and energy saving can create greater value for your company!