There are different types of vibrating screens, each designed for specific applications and industries. Below is an overview of common types, their functions, how they work, and the factors that affect their price and specifications.

Different Types of Vibrating Screens

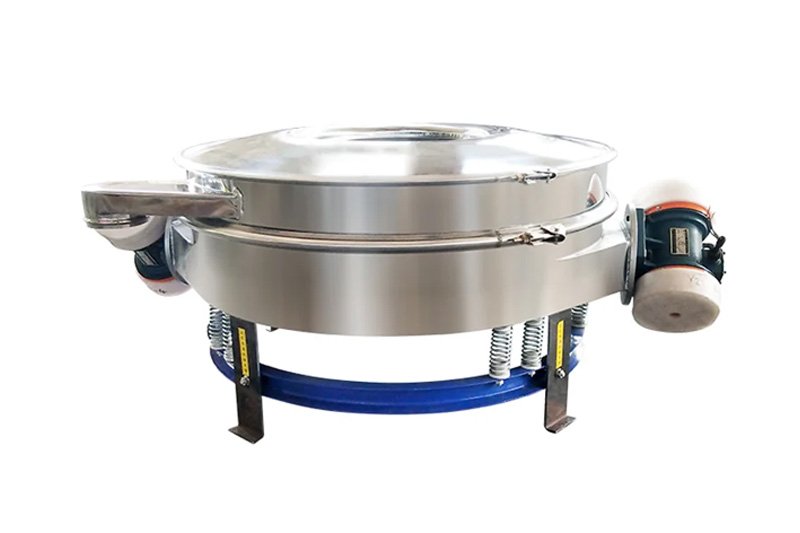

Circular Vibrating Screen

Circular vibrating screen operates in a circular motion, generated by an eccentric shaft with an unbalanced weight on its ends, causing the screen to vibrate in a circular pattern.

Circular vibrating screens are widely used in industries such as food industry, pharmaceutical, chemical, and others for efficient screening and sizing of various materials. Some key advantages of circular vibrating screens include their ability to handle a wide range of materials, their high screening efficiency, and their ability to perform well even with wet and sticky materials.

Tumbler Screening Machine

Tumbler screening machine, also known as a tumbler screener, is a specialized screening equipment designed to perform highly efficient fine particle separation. It is commonly used in industries such as pharmaceuticals, chemical, food processing, and mineral processing, where precise particle size separation is crucial.

The tumbler screen machine operates on the principle of gyratory motion, wherein the material being screened is subjected to a unique tumbling motion along with a series of gyratory vibrations. This motion allows for better dispersion of the material, preventing it from getting trapped in the screen openings and improving the screening efficiency.

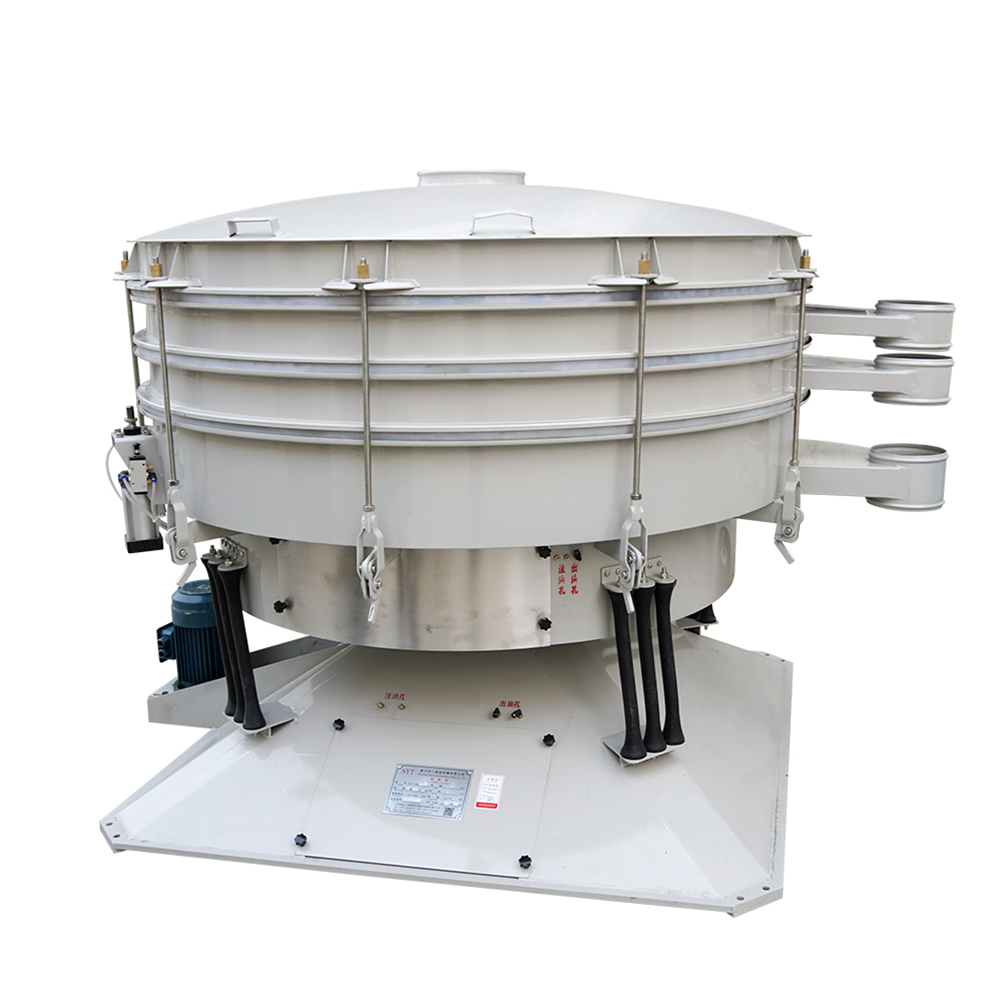

Gyratory Vibrating Screen

Gyratory screen, also known as a gyratory sifter or gyratory separator, is an efficient and reliable screening equipment, particularly when dealing with difficult-to-screen materials or high-capacity requirements. It is an efficient and versatile screening machine commonly used in various industries, including food processing, chemicals, pharmaceuticals, and agriculture.

The gyratory screen consists of a circular screening assembly that is driven by a vibratory motor located beneath the screen surface. The motor imparts a gyratory motion to the screen assembly, causing it to vibrate in a circular path on a horizontal plane. As the material is fed onto the screen, it spreads out evenly due to the gyratory motion.

Linear Vibrating Screen

Linear vibrating screen is a type of screening equipment that is commonly used in mineral processing, coal preparation, and other industrial applications to separate and size particles. It operates on the principle of vibration in a straight-line motion, causing the material to move across the screen and be classified based on its size.

Linear vibrating screens can handle large capacities of material and their simplicity in design and operation. They are efficient for classifying a wide range of materials, from fine powders to coarse particles.

Operating Principle

The vibrating screen operates on the principle of applying vibration to the screen surface, causing the material particles to move and separate based on their size and shape. The vibration is typically generated by electric motors or mechanical excitation systems. The amplitude and frequency of the vibration can be adjusted to optimize the separation process for specific materials.

Function

The primary function of vibrating screens is to separate and classify materials by size and other characteristics. This allows for efficient processing and handling of materials, improving product quality and consistency. The functions of vibrating screens include:

Price

| Products | Model | Layers | Mesh Size | Capacity | 5.5 kW /7.5 kW | Price($/sets) |

|---|---|---|---|---|---|---|

| Circular Vibrating Screen | SY-400/600/800/1000/1200/1500/1800mm | 1-5 | 2-500 mesh | 100kg-3 tons/hour | 0.25-3KW | $799-3899 |

| Tumbler Screen Machine | YBS-1000/1200/1600/2000/2200/2600mm | 1-5 | 5-625mesh | 100Kg-10 tons/hour | 1.5-4KW | $2299-5899 |

| Gyratory Vibrating Screen | FYBS1536 /2040mm | 1-10 | 5-625mesh | 10-20 tons/hour | 5.5 kW /7.5 kW | $7800-13450 |

| Linear Vibrating Screen | SYZ-520/ 525/530/1020/1025/1030/1225mm | 1-5 | 2-200mesh | 100Kg-10Tons/hour | 0.37-1.5KW | $2399-11099 |

The price and specification of vibrating screens can vary widely based on several factors:

- Screen Type and Size: Different screen types and sizes come with varying costs.

- Material of Construction: Screens can be made of stainless steel, carbon steel, or other materials, influencing the price.

- Capacity and Throughput: Higher capacity screens may be more expensive.

- Features: Additional features like dust covers, anti-blinding devices, and automation can affect the price.

- Brand and Manufacturer: Well-known brands or specialized manufacturers may have premium-priced products.

Conclusion

Always consider your specific application requirements when selecting a vibrating screen to get accurate pricing and specifications for the vibrating screen that suits your requirements.

Sanyuantang is a professional vibrating screen factory, we have rich experience in production and design, If you have needs, please contact us to customize a suitable solution for you.

Email: info@sanyuantang.com

Phone: +86-18639095165

FAQs

Related products

Related Articles

- Circular Vibrating Screen Working Principle

- How To Choose Right Vibrating Screen Mesh

- Difference Between Circular Tumbler Screen And Rotary Vibrating Screen

- Vibrating Screen Mesh Size And Pore Size Comparison Table

- Tumbler Screening Machine Benefits And Working Principle

- The Role Of Bouncing Balls In Vibrating Screens

- Vibrating Screen For Sale Australia