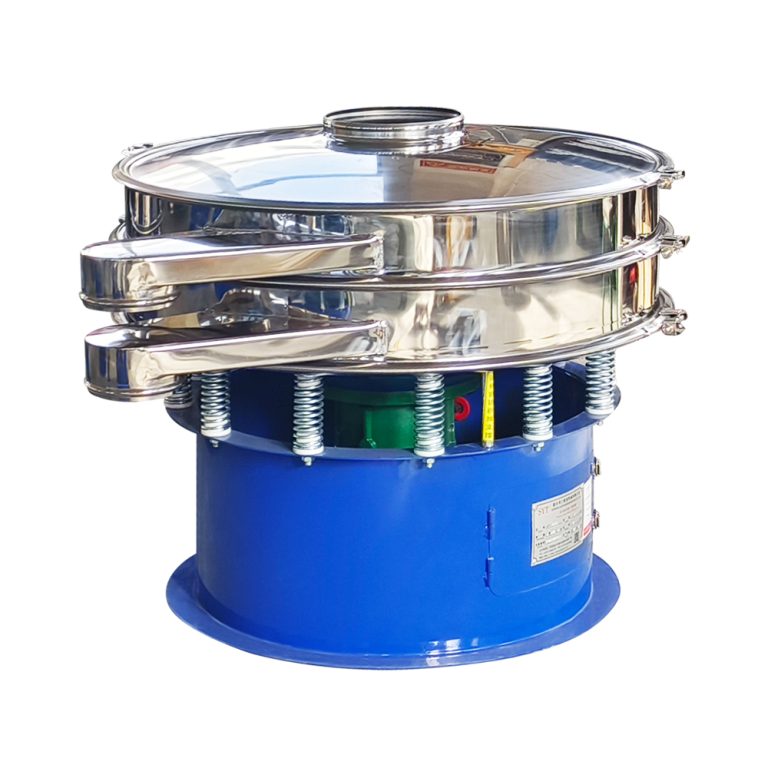

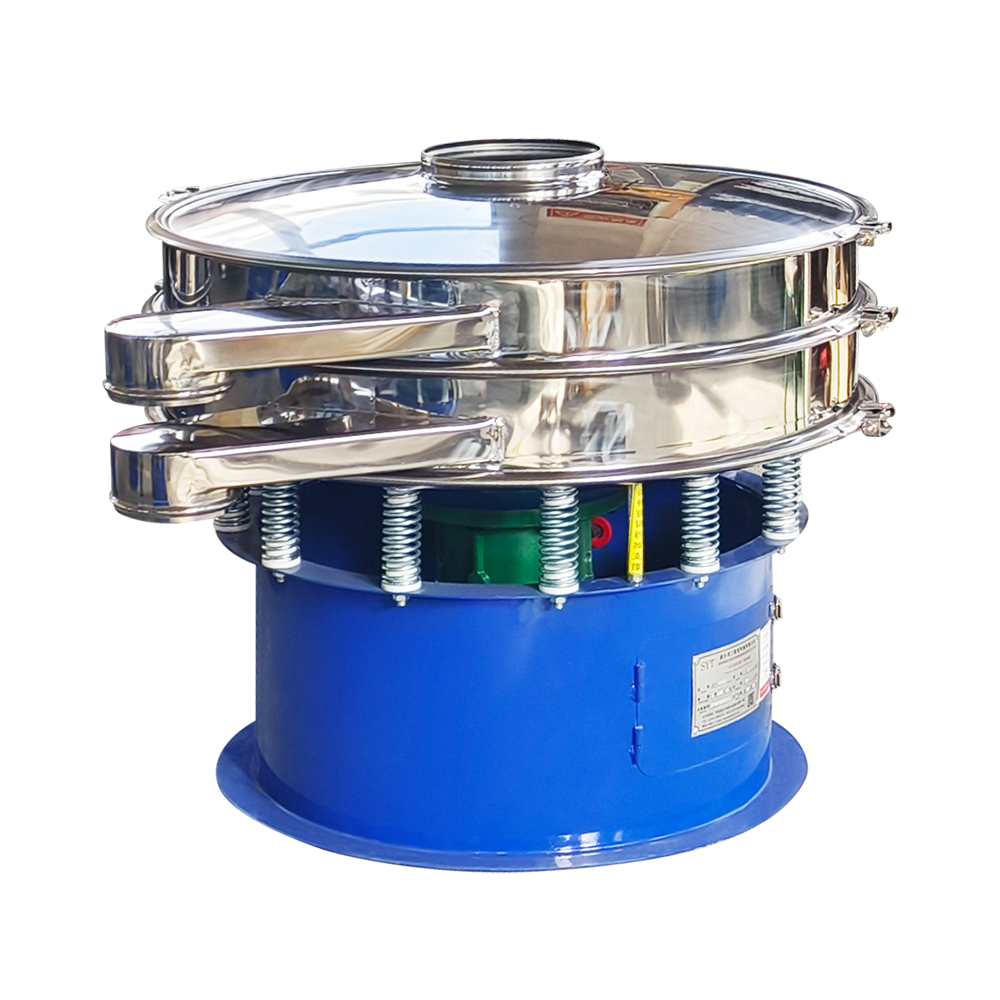

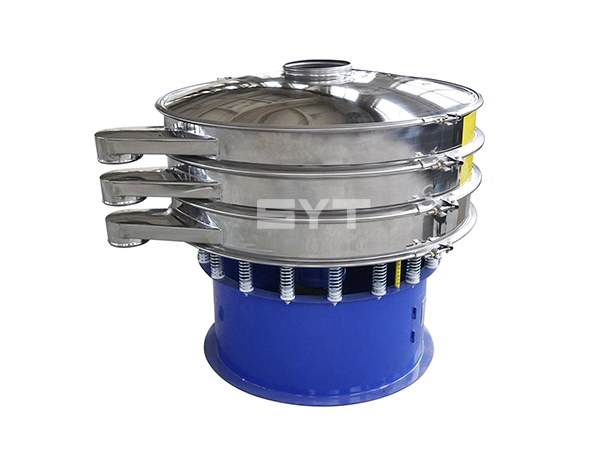

High-efficiency vibro sifter machine to improve the quality of your production

The vibro sifter, also known as a vibrating sieve or vibrating screen separator, is a specialized sifting equipment for screening various materials such as powder, granules, or liquids.

The vibrating sifter machine uses a powerful vertical vibration source, with a screening accuracy of 98%, and achieves high efficiency and high throughput without any screen clogging. Suitable for dry or wet applications such as silica, ceramics, powder coatings, tapioca starch, coffee beans, copper powder, silver powder, etc. We offer a range of customization options to fit your production line and screening needs perfectly.

- Model: SYM-1500mm/1200mm/1000mm/800mm/600mm/400mm

- Material: Stainless Steel 304/316/Carbon Steel

Price: $799.00 – $3,999.00/Set

The industrial vibro sifter uses high-speed vibration motion and an efficient design to achieve fast and thorough screening, maximizing productivity while minimizing downtime. Its user-friendly operation and low maintenance requirements further enhance the overall efficiency of the manufacturing process. The standard models are 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, and 1800mm. (can also be customized).

Screening grade

The vibro sifter is a high-precision fine powder screening machine that can divide materials into 5 grades: coarse powder, medium powder, fine powder, micro-fine powder, and ultra-fine powder. 1-5 layers of screens can be customized and used at the same time according to different needs of customers.

One-Layer

Two Layers

Three Layers

Four Layers

Materials

According to the screening needs of different industries, vibro sifters can be designed in different materials: carbon steel, 304 stainless steel, and PP plastic material.

Contact Part Stainless Steel + Carbon Steel

Full Stainless Steel

Carbon Steel

Anti Corrosion Plastic PP

Special customized design

The vibro sifter can also be specially customized for design, such as gate-type vibrating sifter, edge-type vibrating sifter, and other models.

Add hopper

Add scraper

Extended feed port

Open type

Features

- Customized mesh frame and screen, high screening efficiency, and precision can reach 98%.

- The mesh is not clogged, the powder does not fly, and it can be sieved up to 500 mesh or 0.028mm.

- Wide range of applications, any powder, particles, mucus can be screened.

- Impurities, coarse material automatically discharged, can be continuous operation.

- Compact and durable design, small volume, does not occupy space easy to move.

- 3-5 minutes to change the screen quickly, simple operation, easy to clean.

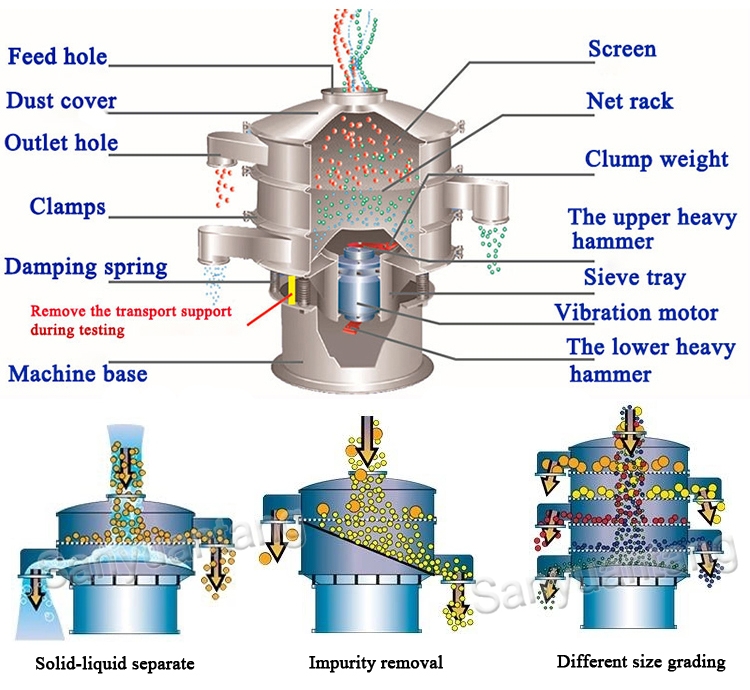

Working Principle

The vibro sifter uses an upright motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights, which convert the rotational motion of the motor into three-dimensional motion of horizontal, vertical, and tilt, and then transfer this motion to the screen surface. The material is made to expand involute motion on the screen surface, so also called as rotary vibrating screen.

The vibro sifter machine mechanism has the advantages of long material running trajectory and high screen surface utilization. Adjusting the phase angle of the upper and lower weights can change the movement trajectory of the material on the screen surface. It can carry out precision screening and probability screening of materials. wait.

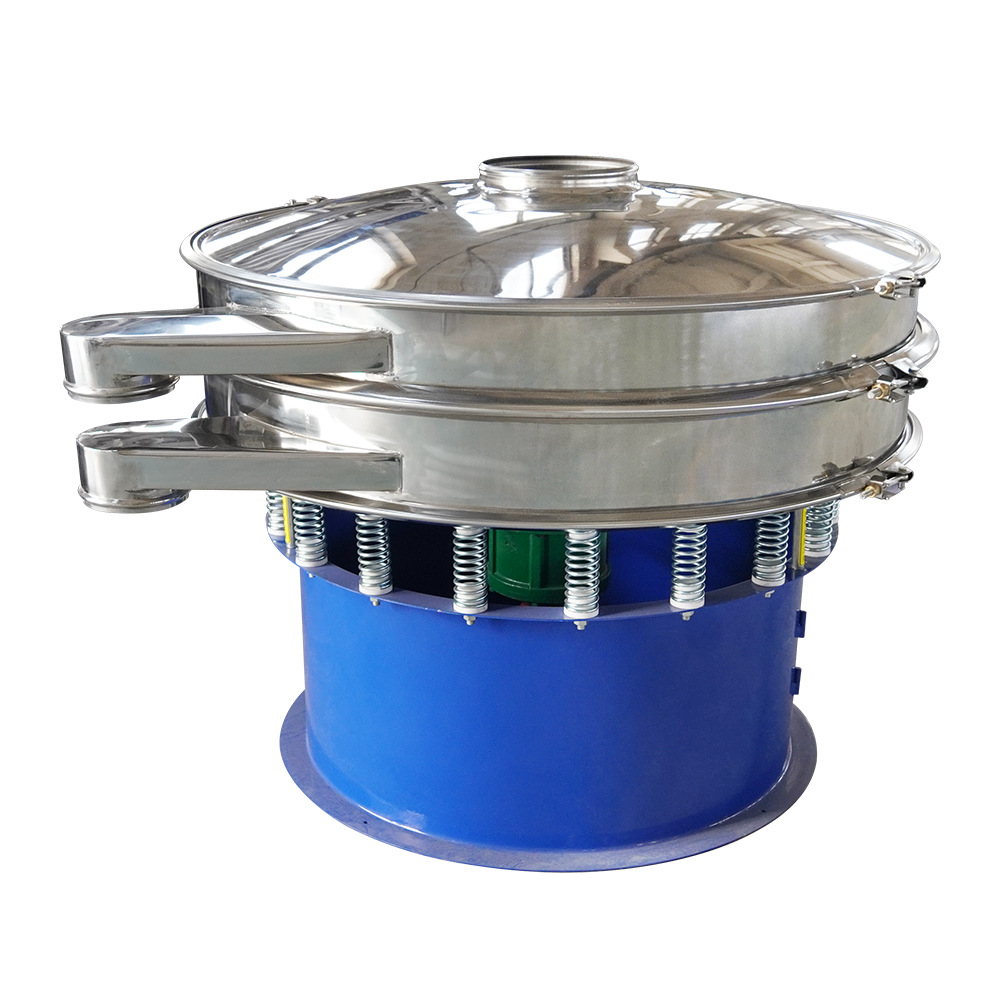

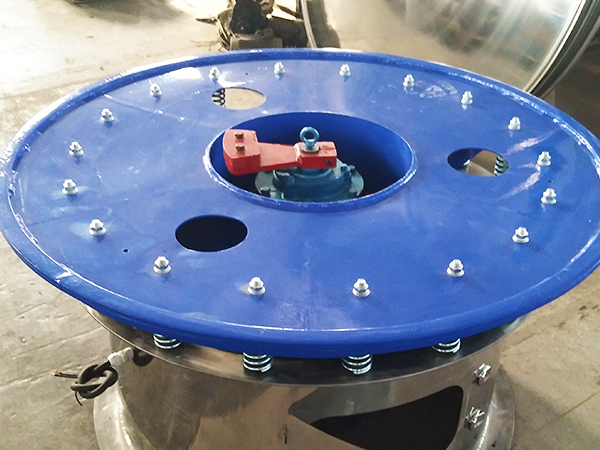

parts of vibro sifter

The parts of vibro sifter mainly consist of the following parts.

Dust cover, feed hole, screen frame, screen mesh, screen frame, beam ring, outlet, vibration motor, vibration transducer, upper and lower weights, vibration isolation spring, spring washer, base.

Feeding Hole

Feeding Hole Outlet Hole

Outlet Hole Screen

Screen Gate

Gate Damping Spring

Damping Spring Vibration Motor

Vibration Motor

Vibration motor: source power

The vibration motor provides the original power for the vibro sifter to work and is the excitation source of the screen machine.

Up and down eccentric weight: key to operation

The excitation force generated by the vibration motor changes the direction of the force through the eccentric weight – into three movement modes: horizontal, vertical, and tilt. Under the combined action of these three forces, the material can be evenly dispersed on the screen. It is screened layer by layer and then discharged from the discharge port.

Spring group: buffering effect

Since the force generated by the vibration motor will cause damage to the screen machine, adding a spring group can buffer the force generated by the motor, prevent the screen frame from being cracked, and extend the service life of the screen machine.

Screen frame, screen frame, screen mesh, beam ring: main body of screening

The screen mesh is placed on the support structure formed by the screen frame. The middle can prevent mesh cleaning pinballs, which can not only reduce the damage of the material to the screen mesh but also clean the screen mesh holes in time. The beam rings fix the screen frames of each layer so that the vibro sifter mechanism can classify materials layer by layer.

Specifications

| Model | Layer (s) | Granularity (mm) | Sieve Mesh | Effective Diameter (mm) | Power (KW) | Capacity(Kg/h) |

|---|---|---|---|---|---|---|

| SY-XZS400 | 1-3 | <20 | 2-500 mesh | 380 | 0.25 | 100 |

| SY-XZS600 | 1-3 | <20 | 3-500 mesh | 580 | 0.55 | 200 |

| SY-XZS800 | 1-5 | <30 | 3-500 mesh | 780 | 0.75 | 500 |

| SY-XZS1000 | 1-5 | <30 | 3-500 mesh | 970 | 1.1 | 800 |

| SY-XZS1200 | 1-5 | <30 | 3-500 mesh | 1170 | 1.5 | 1200 |

| SY-XZS1500 | 1-5 | <50 | 3-500 mesh | 1470 | 2.2 | 1500 |

| SY-XZS1800 | 1-5 | <50 | 3-500 mesh | 1770 | 3.0 | 2000 |

Types of Vibro Sifter

Standard Vibro Sifter

The vibro sifter can be used to screen and filter coarser particles or powders while providing 5 levels of classification to achieve precise particle size distribution and screening up to 500 mesh.

- Mesh size: 2-500mesh

- Capacity: 100-3300 kg/h

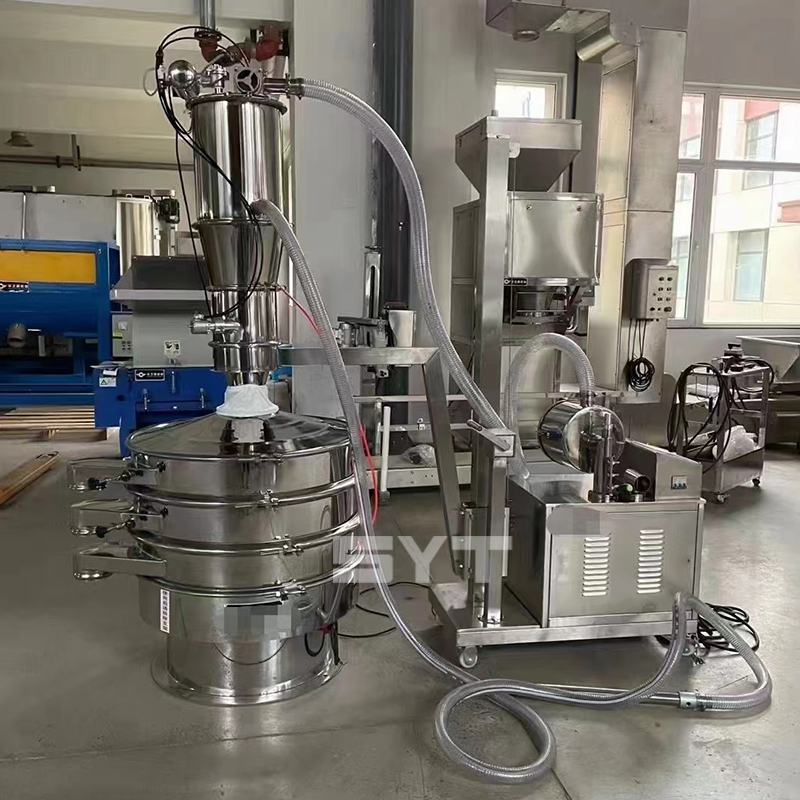

ultrasonic vibro sifter

The ultrasonic vibro sifter uses high-frequency ultrasonic pulses to clean the screen. It has high screening efficiency, does not block the screen, and has high screening accuracy. Compared with ordinary vibro sifter sieves, the output can be increased by 10 times. It is mainly used for powdery materials above 300 mesh and is suitable for screening and filtering sticky and easily adsorbed materials.

- Mesh size: 300-635mesh

- Capacity: 100-5000kg/hr

Videos

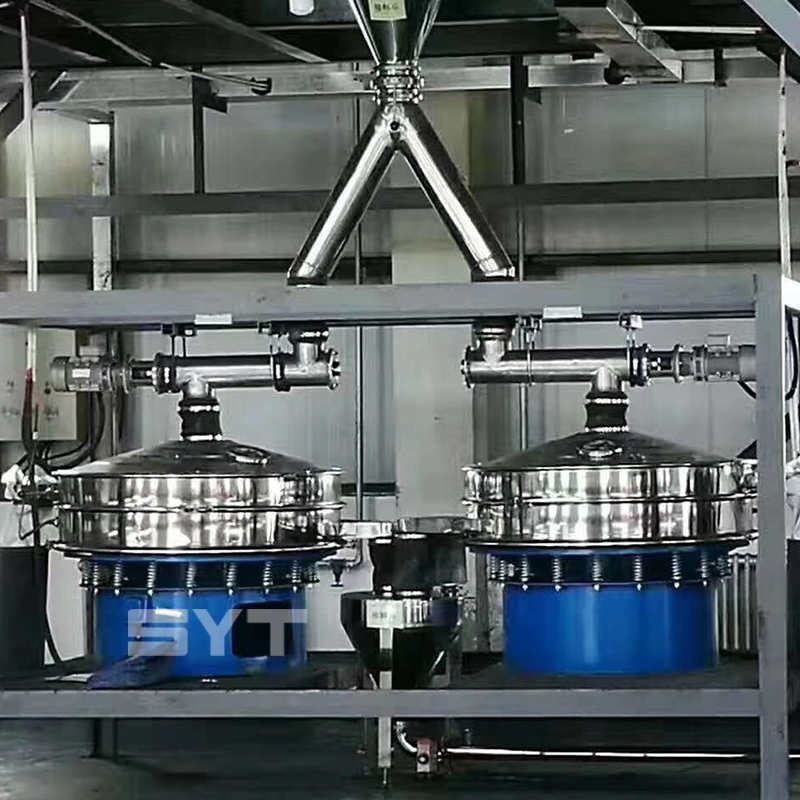

Customer Site

Solutions

| Material | Mesh | Capacity(kg/hr) | Model |

|---|---|---|---|

| Flour | 24 | 2200 | SYM-1500-2S |

| Lime powder | 80 | 800 | SYM-1200-1S |

| Rubber powder | 20/60 | 5000 | SYM-1500-2S |

| Paint coating | 100/150 | 500 | SYM-1000-2S |

| Soy sauce | 100 | 7500 | SYM-1200-2S |